Manufacturers proudly advertise ±0.5% accuracy for electromagnetic flowmeters (EMFs), but field technicians know reality often differs. What really determines your magmeter’s actual performance?

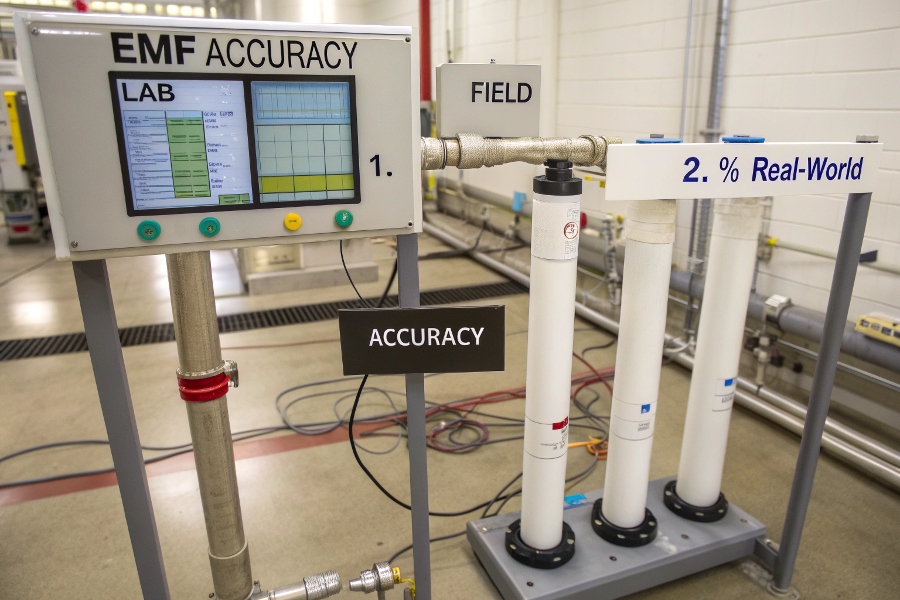

True EMF accuracy requires perfect installation conditions: full pipes with symmetric flow profiles, adequate conductivity (>5 μS/cm), and proper grounding. While lab tests may achieve 0.5% under ideal circumstances, field conditions typically yield 1-2% real-world accuracy due to installation compromises and fluid variations.

Lab vs Field Accuracy

Let’s examine why advertised specs don’t always translate to real piping systems.

Do EMF Apps Actually Work?

Mobile apps claiming to measure magnetic fields cause unnecessary panic.

These apps use smartphone magnetometers that lack proper calibration and sensitivity (typically ±5μT resolution vs professional EMF meters’ 0.01μT). They detect ambient fields but cannot assess actual magmeter performance or compliance with industrial standards like MID or OIML R49.

Measurement Tool Comparison

Understanding measurement limitations prevents costly mistakes:

Why Apps Fail for Industrial Use

| Issue | App Limitation | Professional Solution |

|---|---|---|

| Calibration | No traceable calibration | Annual certified calibration |

| Range | 0-100μT (misses weak fields) | 0.01μT-10T measurement range |

| Frequency | DC-200Hz sampling | 0-100kHz for harmonic analysis |

| Environment | Affected by phone electronics | Shielded probes with ground reference |

| Standards | No industrial certification | IEC 61326 EMC compliance |

Are EMF Concerns Real?

Workplace safety requires distinguishing hazards from myths.

Industrial magmeters generate 0.01-0.1 Tesla fields (100-1000μT) at the pipe wall – below the 5000μT occupational exposure limit (ICNIRP). The alternating fields pose less risk than permanent magnets, with intensity dropping exponentially (inverse square law) from the measurement zone.

Magnetic Field Decay

Practical safety measures address legitimate concerns:

EMF Safety Implementation

Zoning

- Mark 0.5m restricted area during operation

- Install warning labels per ISO 7010

Pacemaker Considerations

- 1m clearance for workers with implants

- Non-magnetic tools in maintenance areas

Field Containment

- Steel conduit routing for excitation cables

- Twisted pair wiring reduces stray fields

Monitoring

- Annual gaussmeter checks at access points

- Logbook for extended exposure workers

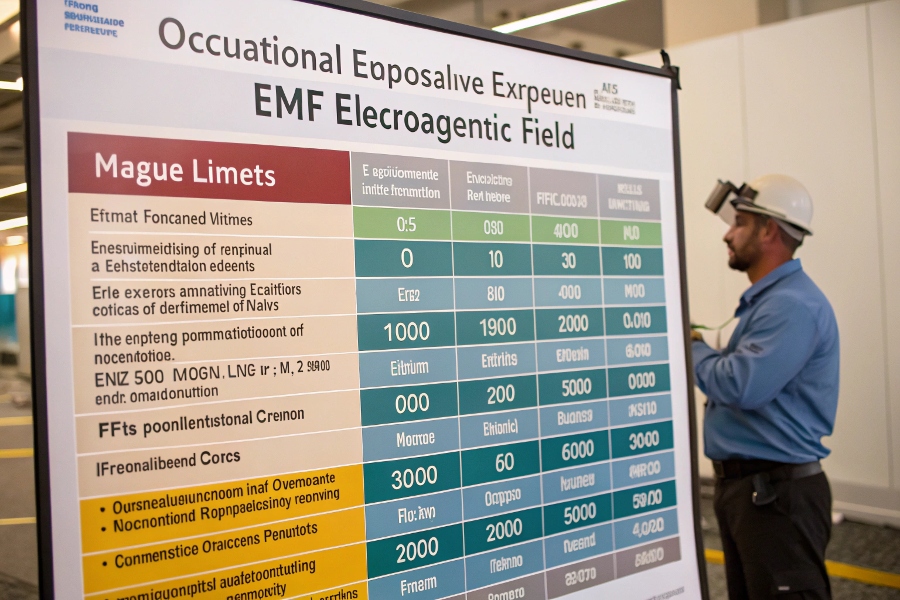

What Is the Acceptable Level of EMF Exposure?

Regulations protect workers without restricting operations.

ICNIRP guidelines allow 5000μT occupational exposure (8hr/day) and 2000μT public exposure. Magmeters typically measure <1000μT at 30cm – well within limits. Special cases like MRI technicians follow different thresholds (200μT continuous).

International EMF Limits

Compliance involves multiple standards:

Regional EMF Regulations

| Region | Standard | Limit (Occupational) | Enforcement |

|---|---|---|---|

| EU | 2013/35/EU | 5000μT | Workplace inspections |

| USA | IEEE C95.1 | 9040μT (1.5kHz) | OSHA complaint-based |

| China | GB 8702-2014 | 4000μT | Environmental audits |

| Japan | MHLW Notice 273 | 3000μT | Equipment certification |

What Is the Average EMF Reading in a Home?

Residential fields pale against industrial equipment.

Typical home readings range 0.01-0.5μT from appliances (<1μT at 30cm). Magmeters in neighboring factories may increase localized readings to 1-3μT – still 1000× below occupational limits. True concerns arise only during maintenance when proximity to exposed coils occurs.

Household EMF Comparison

Real-world measurements reveal actual exposures:

Residential EMF Hotspots

| Source | Typical Field (μT) | Safe Distance |

|---|---|---|

| Refrigerator | 0.5-2 (compressor on) | 0.3m |

| Wi-Fi Router | 0.01-0.1 | N/A (below limits) |

| Power Lines | 0.2-4 (under lines) | 30m buffer zone |

| Industrial Magmeter | 1-10 (factory perimeter) | 5m from pipe |

| Microwave Oven | 10-100 (during use) | 1m (front) |

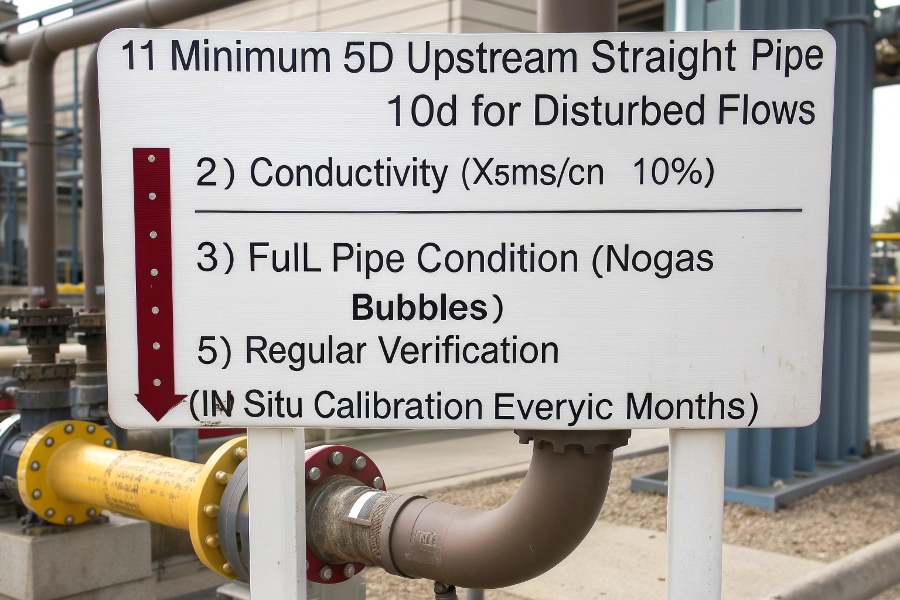

Achieving True 0.5% Accuracy

Precision requires more than buying expensive equipment.

Five critical factors: 1) Minimum 5D upstream straight pipe (10D for disturbed flows), 2) Conductivity stability (>5μS/cm ±10%), 3) Full pipe condition (no gas bubbles), 4) Proper grounding (isolated flange gaskets), and 5) Regular verification (in-situ calibration every 12 months).

Accuracy Maintenance Steps

A structured approach maintains performance:

Accuracy Assurance Protocol

Pre-Installation Checks

- Conductivity lab test with process samples

- Pipe dimensional survey for area calculation

Installation Validation

- Laser alignment of pipe sections

- Ground resistance test (<1Ω)

Commissioning Tests

- Zero stability check (1hr observation)

- Simulated flow test with reference meter

Ongoing Maintenance

- Quarterly electrode inspection

- Annual magnetic field strength test

Conclusion

While EMFs can achieve 0.5% accuracy under ideal conditions, real-world operation typically yields 1-2% due to installation constraints and fluid variability. By understanding the gap between lab specs and field performance, engineers can make informed decisions—prioritizing proper installation over theoretical specs. Regular maintenance and adherence to safety standards ensure reliable measurements