Last month, a chemical plant in Texas lost over $50,000 in product due to inaccurate flow measurement. Their traditional mechanical meter had been quietly failing, leading to incorrect batch mixing. This common scenario highlights why choosing the right flow meter is crucial.

Ultrasonic flow meters use sound wave technology to measure liquid flow, offering non-invasive measurement solutions with accuracy up to ±0.5% for pipes ranging from 15mm to 5000mm. Unlike mechanical meters, they have no moving parts and require minimal maintenance.

Ultrasonic Flow Meter Overview

| Performance | |

|---|---|

| Flow Rate | ±0.03m/s~±12m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% of measured value |

| Linearity | ±1% |

| Pipe Size | DN25-DN1200 |

| Function | |

| Output | Analog output: 4-20mA, Max. load 750Ω ;Pulse output: 0~10KHz |

| Communication | RS232/RS485 Modbus(M-Bus or Hart is optional) |

| Power Supply | 10-36VDC / 90-245VAC |

| Display | 240*128 backlit LCD |

| Temperature | Transmitter:-20℃–60℃;Transducer:-40℃–80℃(TT01,TT02);Transducer:-40℃–130℃(TT03,TT05);Transducer:-40℃–180℃(TT02H);Transducer:0℃–65℃(TT02S);Transducer:0℃–135℃(TT03S) |

| Humidity | Up to 99%RH, non-condensing |

| Physical | |

| Transmitter | PC+ABS, IP65 |

| Transducer | Enccapulated design IP68;Double-shielded transducer cable;Standard/Max. cable length: 30ft/1000ft(9m/300m) |

In my 15 years of experience supplying flow solutions, I’ve seen how proper meter selection can save companies millions in operational costs. Let me share what I’ve learned to help you make an informed decision.

Introduction Of Ultrasonic Flow Meter

One of my clients spent weeks troubleshooting their water treatment process before realizing their flow measurement was off by 15% due to incorrect meter selection.

Ultrasonic flow meters use high-frequency sound waves (typically 0.5-1MHz) to measure liquid flow rate without contacting the media, providing real-time monitoring with digital accuracy and zero maintenance requirements.

Let me break down the core components based on my field experience:

Core Components Explained

Essential Elements

Component Function Real-world Impact Common Issues Transducers Converts electrical signals to ultrasonic waves Determines measurement accuracy Signal degradation over time Controller Processes time differences to flow rate Affects data reliability Software updates needed Display unit Shows flow rate and diagnostics Critical for operators Screen visibility in sunlight Mounting system Ensures proper signal coupling Installation success rate Alignment challenges Modern Features

- Bluetooth connectivity for remote monitoring

- AI-powered signal processing for improved accuracy

- Self-diagnostic capabilities

- Cloud data integration

Working Principle Of Ultrasonic Flow Meter: How Does It Actually Work?

During a recent project at a beverage plant, operators couldn’t understand why their flow readings fluctuated. The issue wasn’t the meter – it was their understanding of how ultrasonic technology works with their specific fluid.

Ultrasonic flow meters calculate flow rates by measuring the time difference between upstream and downstream ultrasonic signals. When fluid moves faster, the time difference increases, allowing precise flow calculation through advanced algorithms.

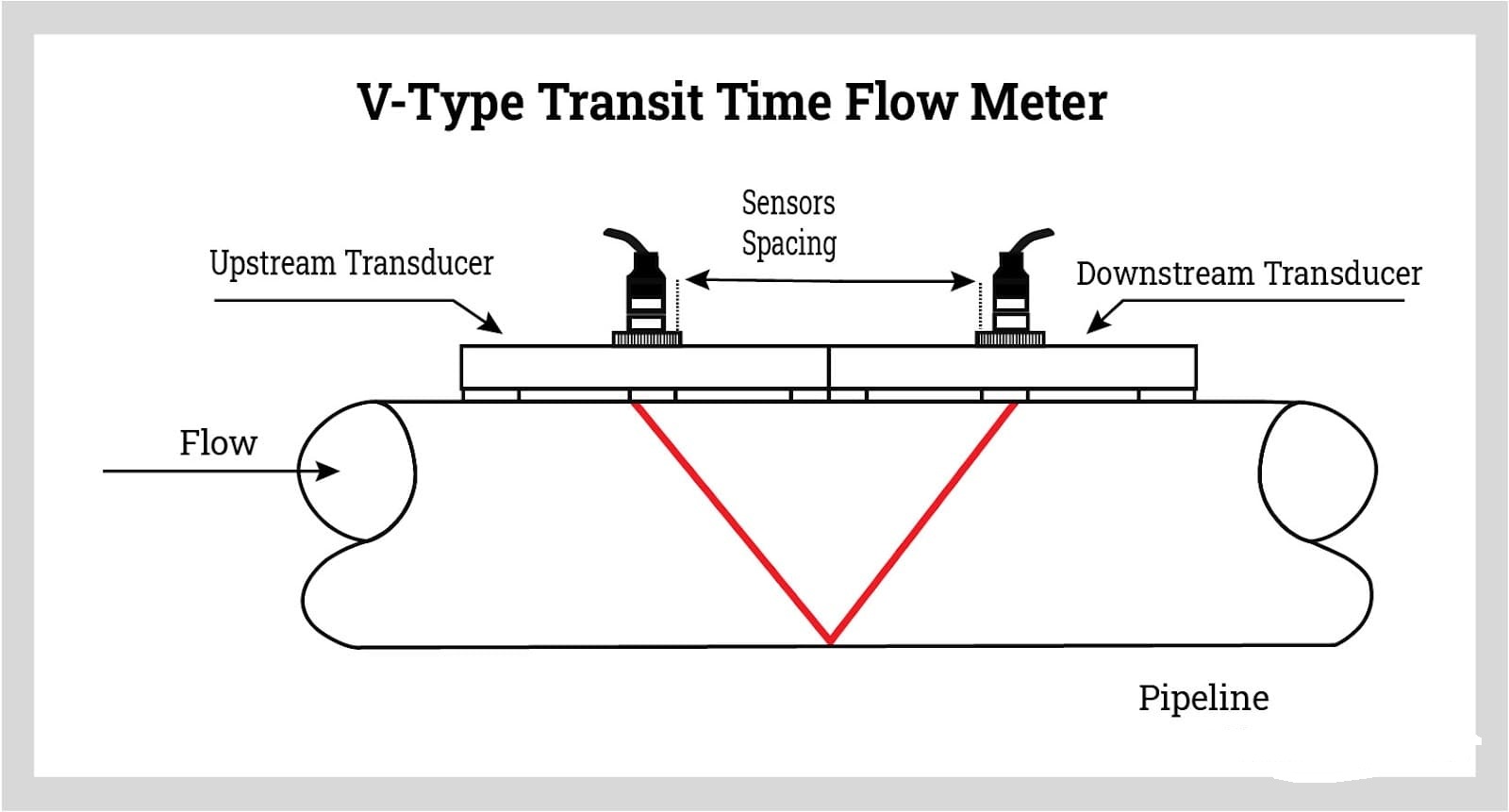

Transit Time Measurement Principle

Here’s what I’ve learned from installing hundreds of meters:

Understanding the Science

Signal Path Analysis

Process Step What Happens Why It Matters Common Mistakes Wave Generation 1MHz signal pulse created Signal strength affects accuracy1 Wrong frequency selection Transit Time Waves travel diagonally Path length crucial for calculation Incorrect angle setting Signal Reception Time difference measured Flow velocity determination2 Poor signal coupling Flow Calculation Algorithm processes data Final flow rate output Calibration errors Critical Parameters

- Reynolds number impact on accuracy

- Sound velocity in different liquids

- Temperature compensation methods

- Signal strength requirements

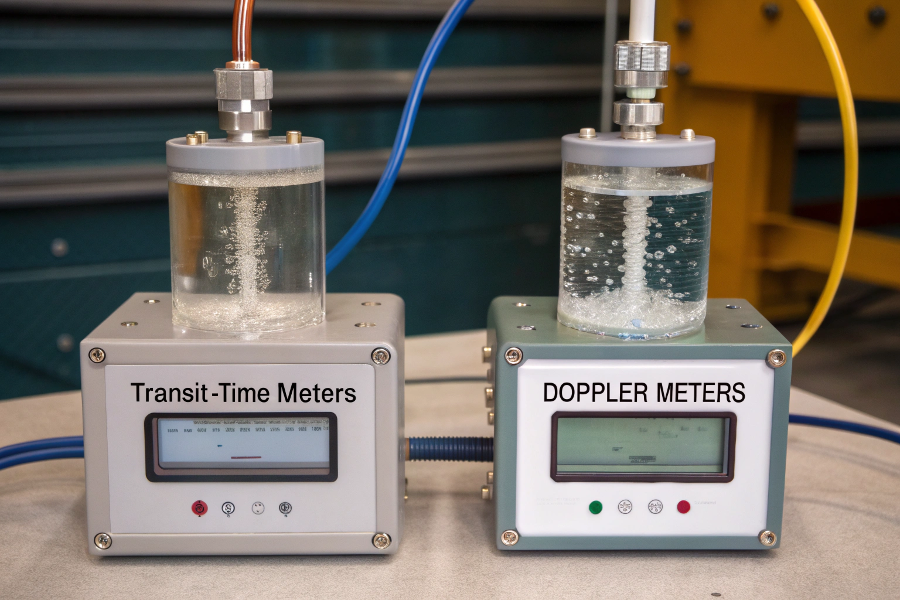

Two Types Of Ultrasonic Flow Meters: Which One Is Right For You?

Last year, a wastewater treatment plant wasted $30,000 on a transit-time meter when they needed a Doppler meter for their particle-laden fluid.

Transit-time meters excel in clean liquids with less than 2% particles, achieving ±0.5% accuracy, while Doppler meters work best in dirty liquids with over 100ppm suspended solids.

Transit-Time vs Doppler Technology

Let me share a decision framework I’ve developed:

Detailed Comparison

Transit-Time Technology

Feature Performance Best Applications Real-world Examples Accuracy ±0.5% Municipal water City water monitoring Price Range $2,000-$8,000 Power plants Boiler feed water Installation More critical Chemical processing Coolant systems Maintenance Annual calibration Food & Beverage CIP systems Doppler Technology

- Handles slurries and sewage

- More tolerant of installation variables

- Lower initial cost ($1,500-$4,000)

- Ideal for mining and wastewater

Advantages And Disadvantages: Real-world Performance Analysis

A power plant engineer once told me he saved $20,000 annually in maintenance costs after switching from magnetic meters to ultrasonic ones. However, they had to invest in proper installation training.

Ultrasonic meters offer non-invasive measurement, zero pressure drop, and maintenance-free operation. However, they require careful installation, clean pipe surfaces, and sometimes struggle with highly aerated liquids.

Based on customer feedback and personal experience:

Real-world Performance

Proven Benefits

Advantage Cost Saving Implementation Example ROI Period No pressure loss $5,000/year energy Cooling systems 6 months Zero maintenance $3,000/year labor Chemical plants 1 year Non-intrusive $10,000 installation Retrofit projects Immediate Long lifespan $15,000 replacement Process lines 2 years Practical Limitations

- Requires 10D upstream, 5D downstream straight run

- Installation expertise needed

- Higher initial investment

- Temperature limitations

Applications: Where Do Ultrasonic Flow Meters Work Best?

Recently, I helped a pharmaceutical company switch to ultrasonic meters for their pure water system. They were amazed by the improvement in batch consistency and reduced contamination risks.

Ultrasonic flow meters excel in applications requiring high accuracy, clean-in-place compatibility, and zero contamination risk. Key industries include pharmaceutical, food & beverage, water treatment, and power generation.

Industry-specific Applications

Here’s my industry-specific analysis based on hundreds of installations:

Industry-Specific Solutions

Application Matrix

Industry Application Success Rate Key Benefits Pharmaceutical Pure water systems 98% Zero contamination Food & Beverage CIP processes 95% Sanitary design Power Generation Cooling systems 92% High temperature Water Treatment Distribution 96% Low maintenance Critical Success Factors

- Proper pipe material selection

- Correct installation location

- Regular calibration schedule

- Environmental protection measures

Buying Guide: How To Choose The Right Ultrasonic Flow Meter?

Last month, I prevented a client from making a $12,000 mistake by helping them understand their actual measurement needs before purchasing.

Select ultrasonic flow meters based on fluid properties, required accuracy, pipe conditions, and budget. Ensure supplier provides installation support, calibration certificates, and after-sales service.

Let me share my proven selection process:

Selection Framework

Technical Requirements

Parameter Consideration Impact Verification Method Flow Range Min/Max flow Sizing Process data analysis Accuracy Required ±% Cost Standard calibration Pipe Size Installation space Model selection Site measurement Environment Temperature/Humidity Protection grade Site survey Commercial Considerations

- Total cost of ownership

- Warranty terms

- Local support availability

- Spare parts accessibility

Installation Tips: Ensuring Optimal Performance

A food processing plant lost three days of production due to poor meter installation. I’ll share how to avoid such costly mistakes.

Proper installation requires careful attention to straight run requirements, transducer mounting, signal cable routing, and grounding. Following manufacturer guidelines can ensure measurement accuracy up to 99.5%.

From my installation supervision experience:

Installation Best Practices

Critical Steps

Step Key Points Common Errors Prevention Location Selection Straight run Insufficient space Pre-installation survey Surface Preparation Clean, smooth Poor contact Proper cleaning tools Transducer Mounting Alignment Wrong spacing Use mounting frames Signal Verification Strong signal Interference Cable protection Post-Installation Checks

- Zero flow verification

- Signal strength testing

- Flow profile analysis

- Documentation completion

FAQ: Common Questions About Ultrasonic Flow Meters

Here are the most common questions I receive from customers:

Q: How often should I calibrate my ultrasonic flow meter?

A: For most applications, annual calibration is sufficient. However, critical processes might require semi-annual verification.

Q: Can ultrasonic meters work with any pipe material?

A: Most common pipe materials work well, but some composites or heavily corroded pipes may cause signal issues.

Q: What’s the minimum flow rate these meters can measure?

A: Modern ultrasonic meters can measure down to 0.1 m/s, but accuracy is best above 0.3 m/s.

I’d love to hear about your experiences with ultrasonic flow meters. Share your stories in the comments below about:

- Your biggest challenges with flow measurement

- Success stories with ultrasonic meters

- Questions about specific applications

Resources and Further Reading

Want to learn more? Here are some valuable resources:

Conclusion

After 15 years in the flow measurement field, I’ve seen ultrasonic technology transform industrial processes. Choose wisely based on your specific needs, invest in proper installation, and you’ll enjoy years of accurate, maintenance-free operation.

Remember: The right meter in the right place can save thousands in operational costs and prevent costly production errors. Don’t hesitate to consult experts for guidance – it’s always cheaper than fixing mistakes later.