Choosing the wrong flow measurement technology can lead to significant accuracy issues and unnecessary maintenance costs in industrial processes.

The most suitable flow measurement technology depends on the fluid type, with Coriolis meters offering highest accuracy for liquids, while ultrasonic meters excel in clean fluids and electromagnetic meters in conductive liquids.

Let me share my experience in selecting flow measurement solutions across different industries.

What Is The Most Accurate Type Of Flowmeter?

Plant managers often struggle with selecting flowmeters that deliver the precision their processes require.

Coriolis flowmeters provide the highest accuracy (up to ±0.1%) for mass flow measurement, while magnetic flowmeters offer similar precision (±0.2%) for volumetric flow in conductive liquids.

From my field experience:

Accuracy Comparison

Technology Rankings

Meter Type Typical Accuracy Best Applications Limitations Coriolis ±0.1% Mass flow, density High cost Magnetic ±0.2% Conductive liquids Conductivity needed Ultrasonic ±0.5% Clean liquids Installation sensitive Vortex ±0.7% Steam, gas Reynolds number dependent Influencing Factors

- Installation conditions

- Fluid properties

- Process parameters

- Environmental conditions

Selection Criteria

Application Requirements

- Process criticality

- Required precision

- Budget constraints

- Maintenance capability

Performance Optimization

- Proper sizing

- Correct installation

- Regular calibration

- Environmental protection

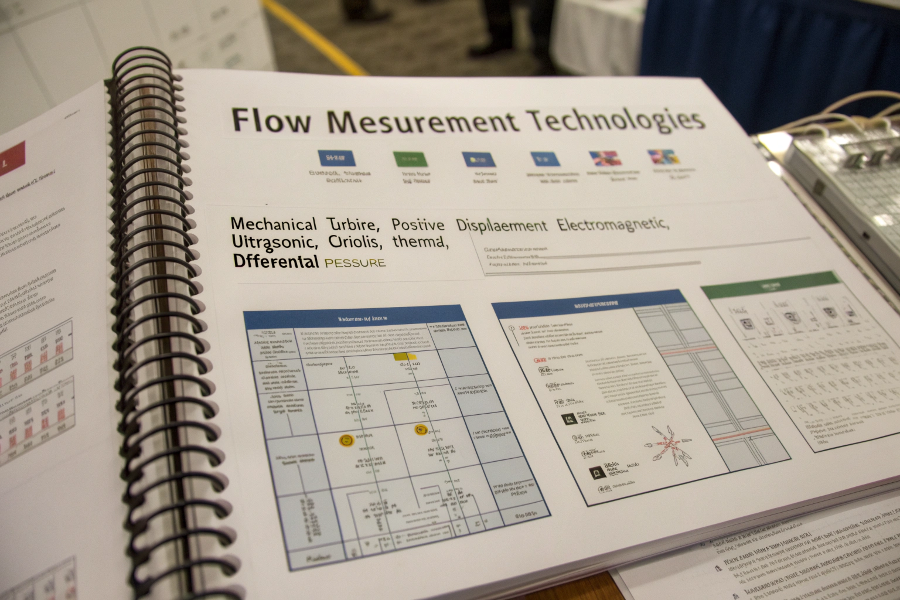

What Technology Is Used To Measure Flow?

Understanding various flow measurement technologies helps in making informed decisions for specific applications.

Flow measurement technologies include mechanical (turbine, PD), electromagnetic, ultrasonic, Coriolis, thermal, and differential pressure principles.

Flow Measurement Technologies in Detail

Based on my implementation experience:

Technology Overview

Operating Principles

Technology Measurement Method Key Advantage Main Application Mechanical Direct displacement Simple, reliable Oil products Electromagnetic Faraday’s law1 No moving parts Water, chemicals Ultrasonic Sound wave transit Non-intrusive Clean liquids Coriolis Mass measurement High accuracy Mass flow Application Considerations

- Fluid characteristics

- Process conditions

- Installation requirements

- Maintenance needs

Implementation Strategy

Selection Process

- Application analysis

- Technology matching

- Cost evaluation

- Life cycle assessment

Operation Planning

- Installation guidelines

- Maintenance procedures

- Staff training

- Performance monitoring

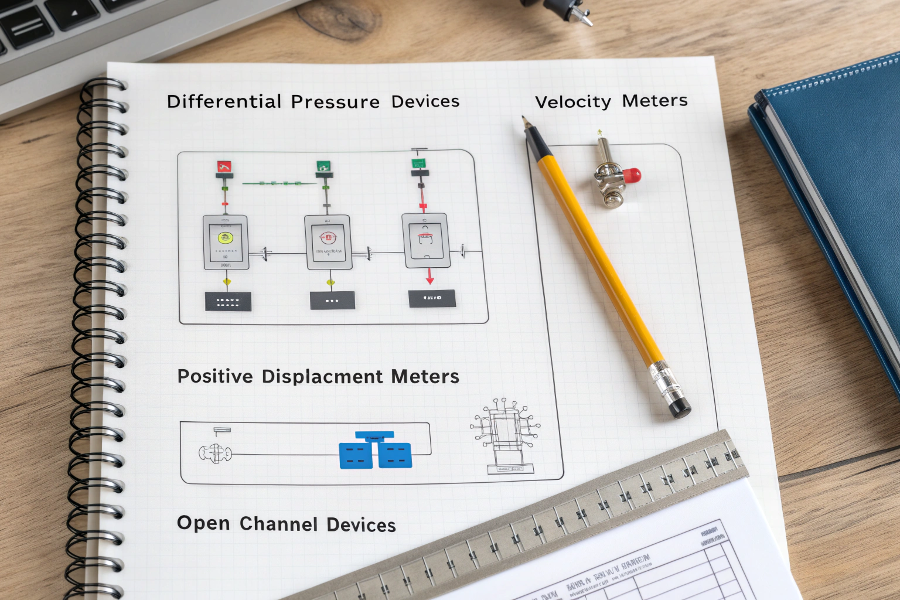

What Are The Different Types Of Flow Measuring Devices?

The variety of flow measuring devices can be overwhelming for those seeking the right solution.

Flow measuring devices include differential pressure devices, velocity meters, positive displacement meters, mass flow meters, and open channel devices.

Types of Flow Measuring Devices

Drawing from my expertise:

Device Categories

Technology Classification

Category Device Types Best For Limitations DP Devices Orifice, Venturi Low cost Pressure loss Velocity Magnetic, Ultrasonic No obstruction Specific conditions PD Meters Gear, Piston High accuracy Moving parts Mass Flow Coriolis, Thermal Direct mass Cost Application Matching

- Process requirements

- Fluid properties

- Installation constraints

- Maintenance capabilities

Selection Guidelines

Decision Factors

- Flow conditions

- Accuracy needs

- Cost considerations

- Maintenance requirements

Implementation Steps

- Site assessment

- Technology selection

- Installation planning

- Performance validation

What Is The Most Accurate Way To Measure Water Flow?

Many industries require precise water flow measurement for process control and billing purposes.

For water flow measurement, electromagnetic flowmeters offer the best combination of accuracy (±0.2%), reliability, and cost-effectiveness, with no pressure loss.

Based on my water industry experience:

Measurement Solutions

Technology Comparison

Method Accuracy Installation Maintenance Cost Magnetic ±0.2% Simple Minimal Medium Ultrasonic ±0.5% Critical Low High Mechanical ±1.0% Standard Regular Low DP Devices ±1.5% Complex Moderate Low Success Factors

- Proper sizing

- Correct installation

- Regular verification

- Environmental protection

Best Practices

Implementation

- Site preparation

- Installation guidelines

- Commissioning procedures

- Performance validation

Maintenance

- Regular checks

- Calibration schedule

- Troubleshooting procedures

- Documentation requirements

Conclusion

Successful flow measurement requires matching the right technology with specific application needs, considering accuracy requirements, fluid properties, and operational constraints for optimal performance.

Understanding Faraday’s law can enhance your knowledge of electromagnetic measurement methods and their applications. ↩