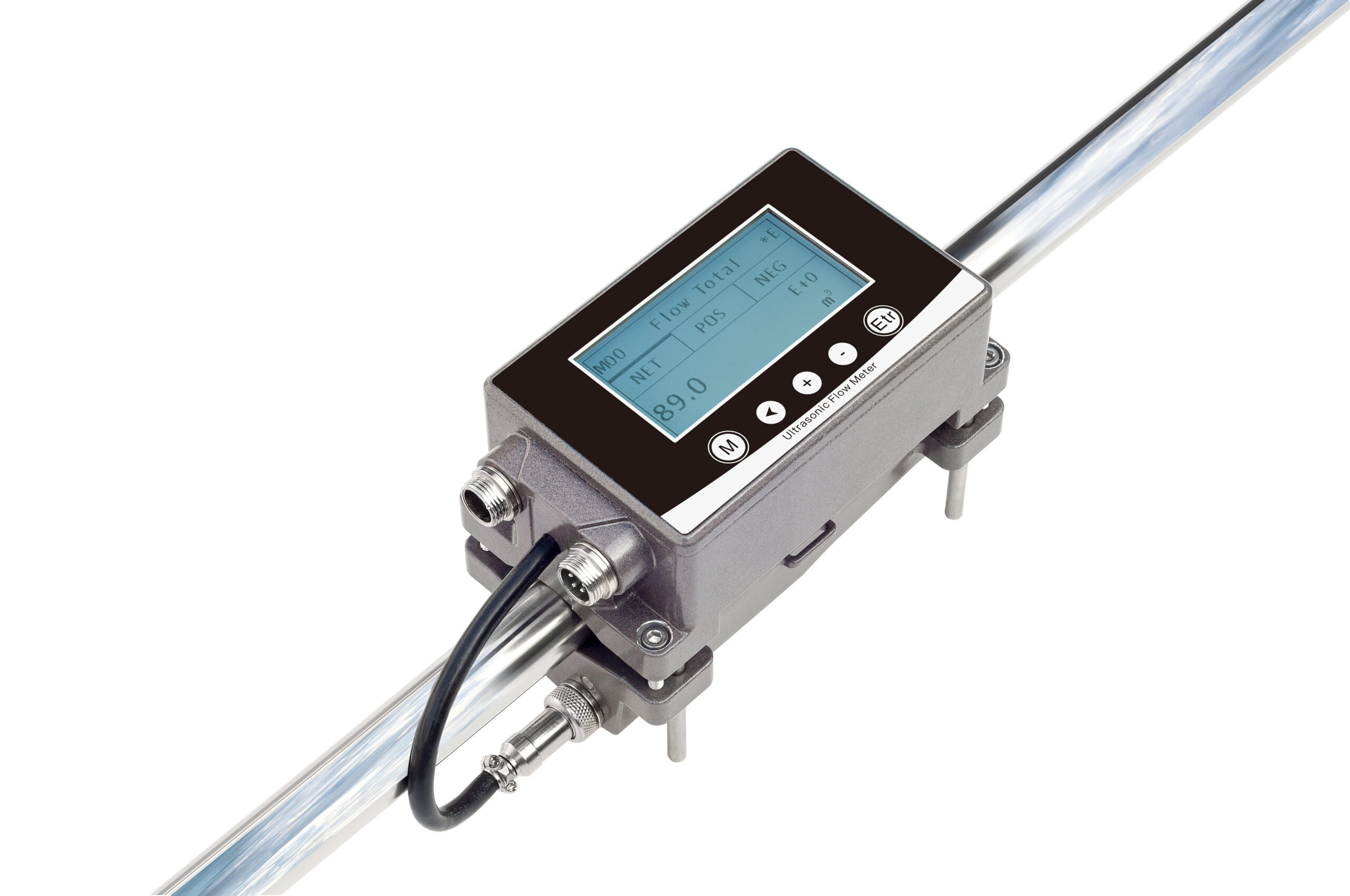

Standard flow meters often fail in specialized small pipe applications, costing companies thousands in inaccurate measurements and downtime. Custom ultrasonic solutions solve these precision challenges.

Customized ultrasonic flow meters for small pipes (6-50mm) overcome 3 key limitations: 1) They handle difficult fluids using specialized transducers (PVDF for chemicals, PEEK for high temps), 2) Adapt to space constraints with compact housings, and 3) Achieve ±0.25% accuracy through calibrated measurement paths tailored to pipe geometry. These modifications cost 15-30% more but improve performance by 40-60%.

Ultrasonic Flow Meter for Small Pipes

The true value emerges when standard meters can’t meet application demands. Here’s how customized solutions bridge the gap.

What Are the Disadvantages of an Ultrasonic Flow Meter?

Seven challenges that customization solves:

Standard vs. Customized Performance

| Limitation | Standard Meter Issue | Custom Solution |

|---|---|---|

| Dirty Liquids | Signal attenuation | High-power 2MHz transducers |

| Pulsating Flow | Measurement errors | Advanced DSP algorithms |

| Small Pipe Vibration | Noise interference | Vibration-damped mounting |

| High-Temperature Steam | Transducer failure | Ceramic sensors (250°C rated) |

| Low Flow Rates | Detection failure | Optimized beam angles |

| Non-Circular Pipes | Accuracy drift | Path geometry compensation |

| Mixed-Phase Flow | Incorrect readings | Multi-frequency discrimination |

When Customization Costs Pay Off

- Chemical injection systems

- Semiconductor cooling loops

- Pharmaceutical batch processes

- Food-grade sanitary applications

- High-pressure hydraulic circuits

- Nuclear cooling systems

- Cryogenic transfer lines

How to Make an Ultrasonic Flow Meter?

Five-step customization process for small pipes:

Custom Build Components

Transducers

- Material: Choose between PVDF, PEEK, or ceramic

- Frequency: 1MHz for dirty fluids, 5MHz for clean

- Mounting: Clamp-on, weld-on, or insert

Pipe Adaptations

- Small pipe collars

- Flow conditioners

- Special couplings

Electronics

- Signal processors

- Noise filters

- Output cards

Software

- Fluid property databases

- Flow profile compensation

- Diagnostic routines

Housing

- Explosion-proof

- Sanitary

- Submersible

Custom Build Steps

Critical Small Pipe Considerations

Beam Path Calculation

- 30°-55° refraction angles

- Multiple reflections in tiny pipes

- Window material thickness

Signal Processing

- Adaptive gain control

- Noise rejection

- Time-of-flight algorithms

Mechanical Design

- Minimal protrusion

- Cleaning access

- Pressure containment

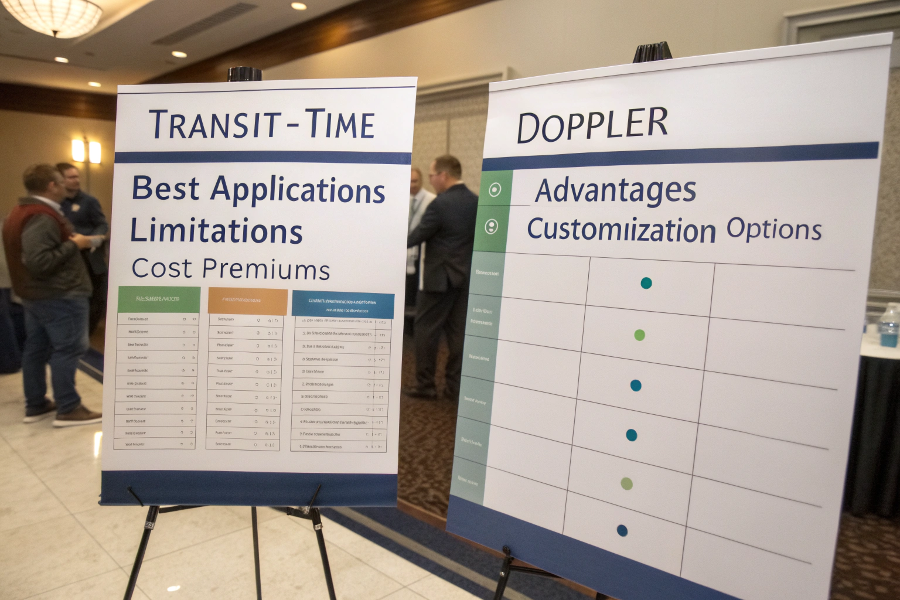

What Are the Two Types of Ultrasonic Flow Meters?

Specialized adaptations for small pipes:

Comparative Analysis

| Feature | Transit-Time | Doppler |

|---|---|---|

| Best For | Clean liquids, gases | Slurries, aerated fluids |

| Small Pipe Advantage | Higher accuracy (±0.5%) | Handles particles |

| Limitation | Requires 0.3 m/s minimum | ±2-5% accuracy |

| Customization Options | Multi-path, dual-frequency | Beam focusing, frequency agility |

| Cost Premium | 15-25% | 30-50% |

Type Selection Guide

Hybrid Solutions Emerging

- Combined Transit-Doppler – Switch modes automatically

- Multi-Path Doppler – Improved slurry accuracy

- Variable Angle – Adapts to flow profile

- Bi-Directional – Reverse flow detection

- Integrated Density – Mass flow calculation

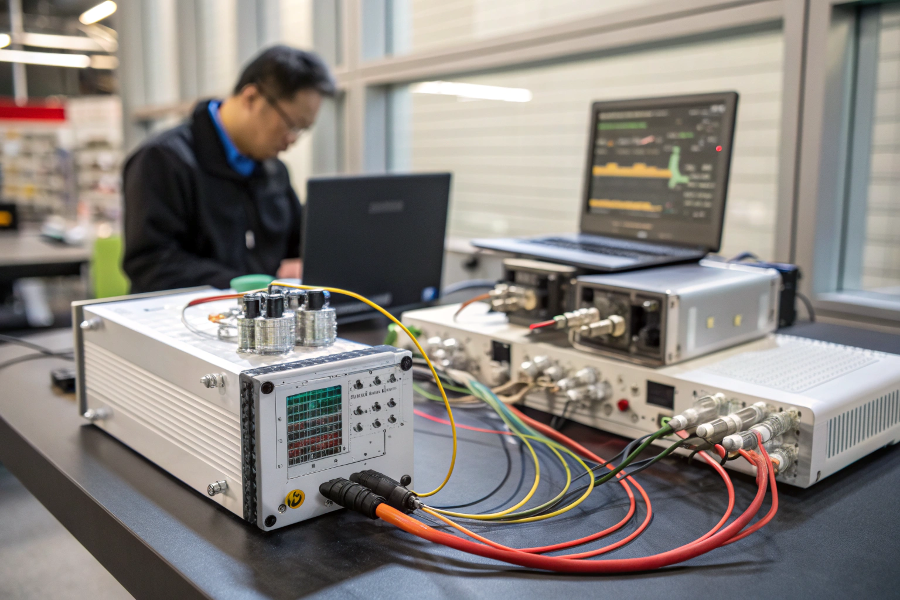

What Is the Technology of Ultrasonic Flow Meter?

Core innovations reshaping small pipe measurement:

Five Breakthrough Technologies

Microbeam Focusing

- 2mm beam width in 6mm pipes

- Reduced wall interference

- Better low-flow detection

Adaptive Signal Processing

- Real-time SNR optimization

- Dynamic filter adjustment

- Pattern recognition

Composite Transducers

- Wider temperature range (-200°C to 300°C)

- Chemical resistance

- Reduced acoustic impedance

Smart Diagnostics

- Coating detection

- Transducer health monitoring

- Flow profile analysis

Wireless Configuration

- Mobile device setup

- Cloud calibration

- Remote troubleshooting

Cutting-Edge Features

Small Pipe Specific Enhancements

- Microfluidic channel designs

- Pipe-dependent algorithms

- Vibration compensation

- Miniature signal converters

- Integrated temperature compensation

Conclusion

Customized ultrasonic flow meters transform performance in small pipe applications, overcoming traditional limitations through tailored transducer designs, advanced signal processing, and specialized mechanical configurations. While demanding higher initial investment, these purpose-built solutions deliver unmatched accuracy and reliability in 6-50mm pipelines, particularly for challenging fluids and demanding process conditions. The technology continues advancing through microbeam focusing, adaptive algorithms, and smart diagnostics – pushing the boundaries of what’s measurable in confined spaces.