Lost revenue from flow measurement errors often goes unnoticed until audits reveal shocking losses. Ultrasonic technology provides the financial visibility needed for small pipe systems.

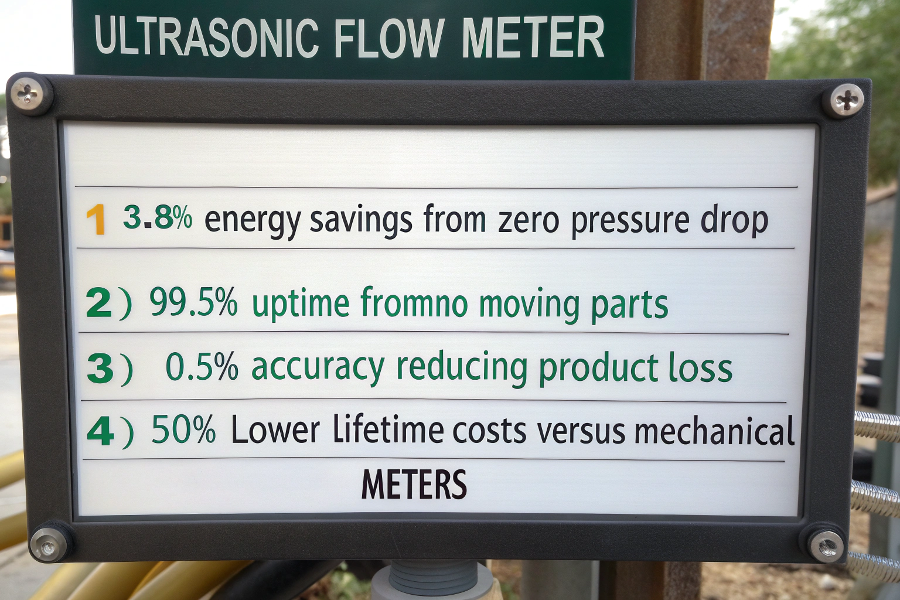

Ultrasonic flow meters deliver 4 key economic benefits in small pipes: 1) 3-8% energy savings from zero pressure drop, 2) 99.5% uptime from no moving parts, 3) ±0.5% accuracy reducing product loss, and 4) 50% lower lifetime costs versus mechanical meters. Their non-intrusive design avoids production shutdowns during installation/maintenance.

Economic Benefits Breakdown

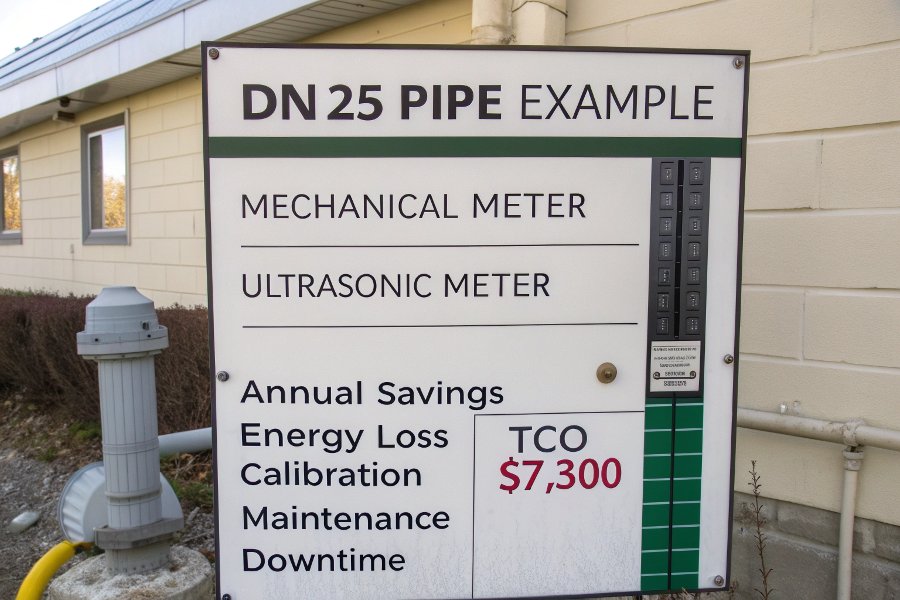

While the upfront cost seems higher, the total cost of ownership tells a different story. Let’s examine the real financial impact.

What Are the Benefits of Ultrasonic Flow Meter?

Six financial advantages transform small pipe operations:

Cost Savings Comparison (DN25 Pipe Example)

| Cost Factor | Mechanical Meter | Ultrasonic Meter | Annual Savings |

|---|---|---|---|

| Energy Loss | $2,400 | $0 | $2,400 |

| Calibration | $800 | $300 | $500 |

| Maintenance | $1,200 | $100 | $1,100 |

| Downtime | $3,500 | $200 | $3,300 |

| Total Savings | $7,300 |

Hidden Value Drivers

- Leak Detection – 2-5% flow loss prevention

- Process Optimization – 1-3% yield improvement

- Data Accessibility – Remote monitoring savings

- Longer Lifespan – 15 vs. 7 year replacement

- Regulatory Compliance – Avoided penalties

5-Year Cost Analysis

Application-Specific Savings

- Chemical Injection: 5-15% material cost reduction

- HVAC Systems: 8-12% pump energy savings

- Water Treatment: 3-5% lower chemical usage

- Food Production: 2-4% less product giveaway

- Pharmaceuticals: Meets FDA audit requirements

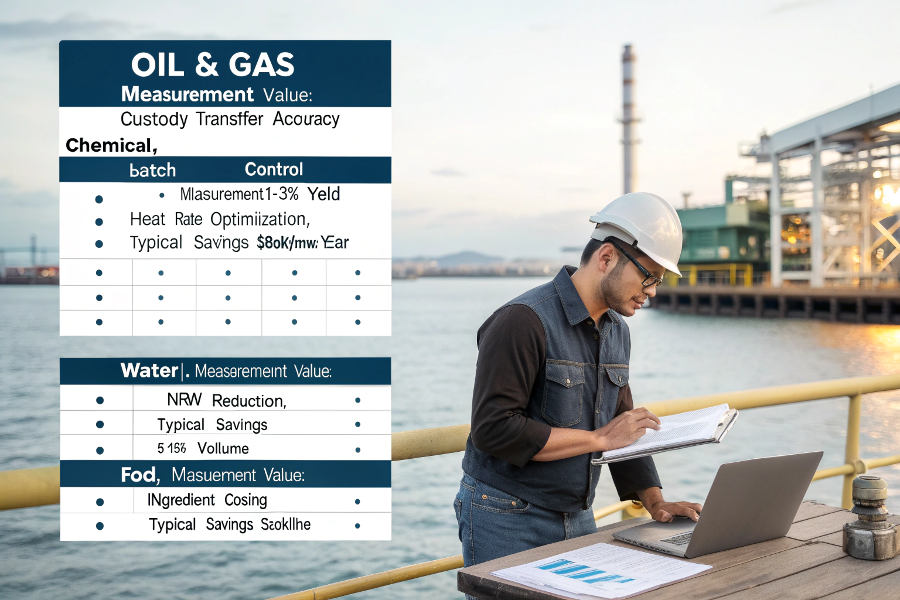

Why Is Flow Measurement Important in Industries?

Precision flow data impacts every business metric:

Financial Impact Areas

| Industry | Measurement Value | Typical Savings |

|---|---|---|

| Oil & Gas | Custody transfer accuracy | $250k/year |

| Chemical | Batch process control | 1-3% yield |

| Power | Heat rate optimization | $80k/MW-year |

| Water | NRW (Non-Revenue Water) reduction | 5-15% volume |

| Food | Ingredient costing | $50k/line |

Small Pipe Critical Applications

- Additive Dosing – ±1% error = $100k in chemicals

- Coolant Flow – 5% drop = $25k equipment failure

- Lubrication Systems – Low flow = $50k bearing damage

- Sampling Lines – Inaccuracy voids $1M tests

- Purge Gas – Wrong flow = $10k sensor loss

Cross-Industry Benefits

Regulatory Drivers

- ISO 50001 energy audits

- EPA effluent monitoring

- FDA 21 CFR Part 11

- Safety instrumented systems

- Trade measurement laws

Which Flow Device Is Suitable for Measuring Large Pipes?

Contrasting small vs. large pipe solutions:

Technology Comparison

| Parameter | Small Pipes (<DN50) | Large Pipes (>DN300) |

|---|---|---|

| Best Technology | Ultrasonic | Electromagnetic |

| Installation | Clamp-on saves cost | Full-bore necessary |

| Accuracy | ±0.5-1% | ±0.2-0.5% |

| Cost Factor | $1,500-5,000 | $15,000-50,000 |

| Lifetime | 15+ years | 20+ years |

When Ultrasonic Works in Large Pipes

- Water/wastewater (clean)

- HVAC systems

- Non-conductive fluids

- Temporary measurements

- Retrofit situations

Scale Adaptation

Large Pipe Alternatives

- Electromagnetic – Best for conductive fluids

- Insertion Vortex – Economical for steam

- Annubar – Low-cost differential pressure

- Insertion Thermal – For gas applications

- Woltmann – High-volume water

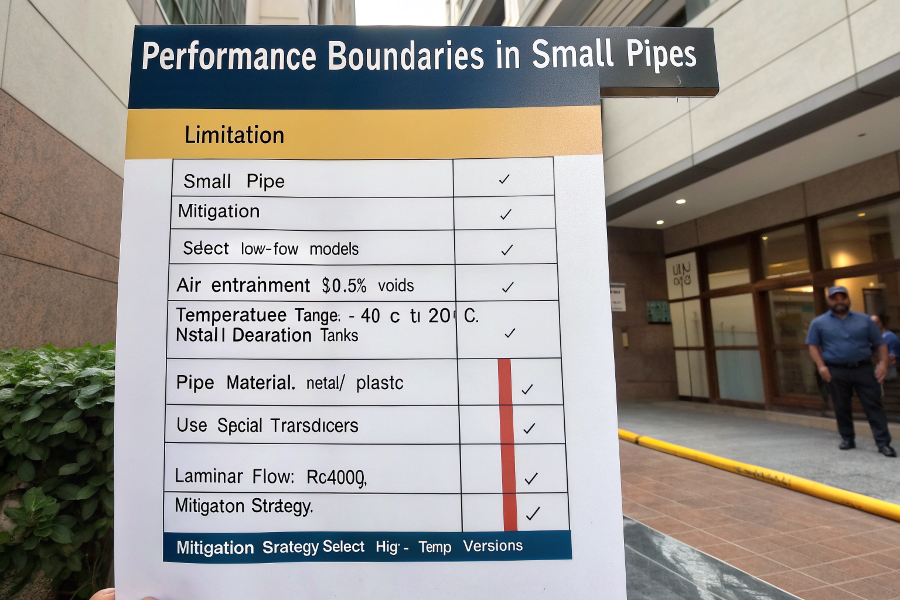

What Are the Limitations of Ultrasonic Flow Meter?

Understanding small pipe constraints:

Performance Boundaries in Small Pipes

| Limitation | Small Pipe Impact | Mitigation Strategy |

|---|---|---|

| Minimum Velocity | 0.3 m/s | Select low-flow models |

| Air Entrainment | >0.5% voids | Install deaeration tanks |

| Pipe Material | Metal/plastic | Use special transducers |

| Laminar Flow | Re<4,000 | Add flow conditioners |

| Temperature Range | -40°C to 200°C | Select high-temp versions |

Economic Constraints

- Higher initial cost ($2k vs. $500 mechanical)

- Special training required

- Need for periodic verification

- Limited rental market

- Fewer repair options

Technical Tradeoffs

When Not to Choose Ultrasonic

- Slurries >5% solids

- Coating fluids

- Non-homogeneous mixtures

- Rapidly changing flows

- Pipes with heavy insulation

Conclusion

Ultrasonic flow meters deliver measurable economic benefits for small pipe systems, typically paying for themselves within 6-18 months through energy savings, reduced maintenance, and improved process control. While presenting some technical limitations, their financial advantages over mechanical alternatives make them the preferred choice for DN10-DN50 pipelines in most industries. Proper selection and installation ensures these benefits are fully realized while avoiding potential measurement pitfalls.