Incorrect positioning between flow meters and control valves can cause measurement errors up to 30% and damage expensive equipment.

Flow meters should typically be installed upstream of control valves to avoid flow disturbances, with a minimum straight pipe run of 5-20 pipe diameters between them.

Flow Meter and Control Valve Positioning

Let me share my field experience to help you make the right installation decisions.

Are Flow Control Valves Upstream or Downstream of Flow Meter?

Many engineers face challenges deciding the optimal arrangement of flow meters and control valves.

Flow control valves should be installed downstream of flow meters to ensure stable flow profiles and accurate measurements, with sufficient straight pipe runs between them.

From my installation experience:

Position Analysis

Installation Requirements

Component Position Straight Run Flow Meter Upstream 5-20D before Control Valve Downstream 2-5D after Pipe Support Both sides As needed Isolation Valve Both ends Maintenance Critical Factors

- Flow profile stability

- Pressure drop management

- Cavitation prevention

- Maintenance access

Implementation Guidelines

Design Considerations

- Space requirements

- Pressure ratings

- Flow characteristics

- Control stability

Performance Factors

- Measurement accuracy

- Control response

- System protection

- Maintenance ease

Proper positioning ensures optimal performance.

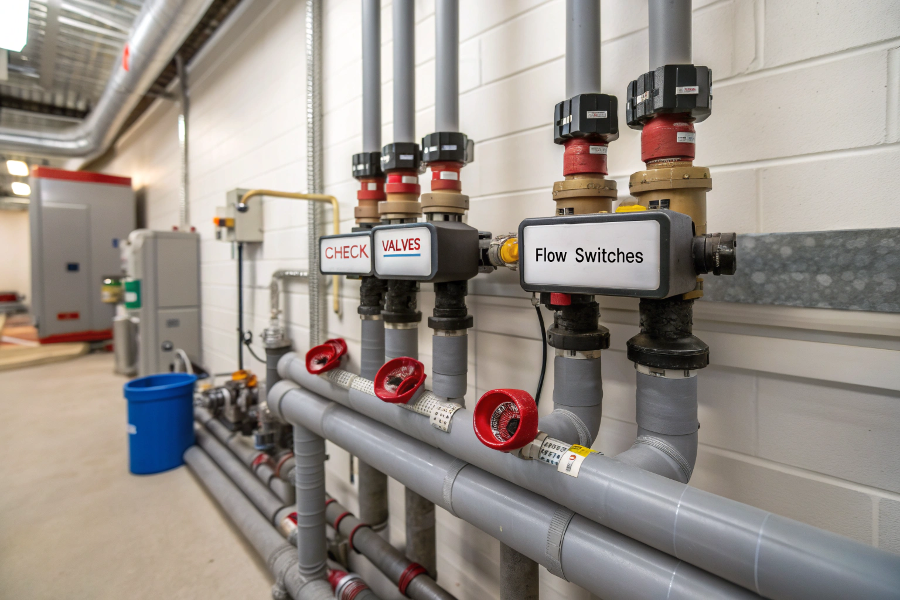

Does the Flow Switch Go Before or After the Check Valve?

Flow switch placement relative to check valves affects system protection reliability.

Flow switches should be installed after check valves to prevent false readings from backflow and ensure accurate flow detection.

Flow Switch and Check Valve Configuration

Here’s what I’ve learned:

Configuration Analysis

Placement Options

Position Advantage Disadvantage After Check Protected Space needed Before Check Early warning False alarms Combined Compact Complex Separate Flexible Cost higher Important Considerations

- Flow direction

- Backflow prevention

- System protection

- Maintenance access

Installation Guidelines

Setup Requirements

- Proper orientation

- Sufficient spacing

- Signal connections

- Access points

Operation Aspects

- Regular testing

- Performance monitoring

- Maintenance schedule

- Documentation

Correct placement improves protection.

Does the Check Valve Go Before or After the Water Meter?

Check valve positioning affects water meter accuracy and system protection.

Install check valves after water meters to protect the meter from backflow while maintaining measurement accuracy and flow profile stability.

Check Valve and Water Meter Setup

Based on my expertise:

Installation Layout

Component Arrangement

Position Component Purpose First Strainer Protection Second Water Meter Measurement Third Check Valve Backflow Fourth Isolation Maintenance Key Requirements

- Flow direction

- Pressure ratings

- Space allowance

- Access needs

System Protection

Design Elements

- Proper sizing

- Material compatibility

- Pressure class

- Connection type

Maintenance Aspects

- Regular inspection

- Performance checks

- Cleaning schedule

- Record keeping

Proper sequence ensures protection.

Should Flow Sensor Go Before or After Master Valve?

Master valve placement affects flow sensor accuracy and system control.

Flow sensors should be installed upstream of master valves to ensure accurate readings and protect the sensor from potential pressure surges.

Flow Sensor and Master Valve Layout

From my installation experience:

Layout Configuration

Position Analysis

Component Location Consideration Flow Sensor Upstream Accuracy Master Valve Downstream Control Straight Run Between Stability Support Both sides Protection Critical Elements

- Flow stability

- Pressure control

- Signal quality

- Maintenance access

Implementation Steps

Design Requirements

- Space planning

- Support structure

- Signal routing

- Access provision

Operation Factors

- Performance monitoring

- Regular maintenance

- Calibration checks

- Documentation

Proper arrangement ensures reliability.

Conclusion

Correct positioning of flow meters relative to control valves, check valves, and master valves is crucial for system protection, accurate measurement, and reliable operation of your fluid handling system.