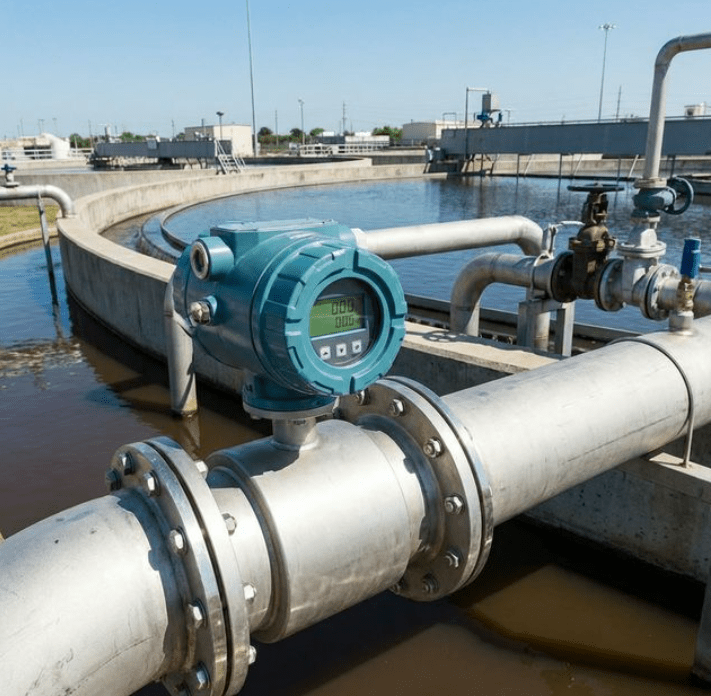

Every wastewater treatment operator knows the frustration: you’ve just replaced a clogged Venturi meter on your return activated sludge line—for the third time this year. At Soaring Instrument, we’ve worked with dozens of WWTPs across Asia and seen this exact scenario play out. The cost? Not just equipment, but hours of unreliable flow data affecting your entire biological treatment process.

Quick Answer: Magnetic flow meters (mag meters) are the gold standard for measuring sludge and slurry flows because they have zero internal obstructions, operate on Faraday’s Law of electromagnetic induction, and work flawlessly with conductive, particle-laden fluids. Unlike mechanical meters, mag meters keep measuring accurately while your sludge keeps flowing—no clogs, no wear, no guesswork.

For wastewater facilities struggling with return activated sludge (RAS) measurement, magnetic flow meters aren’t just an option—they’re the solution that finally makes your flow data trustworthy.

Why Sludge & Slurry Flow Measurement Is So Challenging

Before diving into solutions, let’s acknowledge why sludge and slurry applications give engineers nightmares:

The Triple Threat of Slurry Measurement

| Challenge | What Happens | Impact |

|---|---|---|

| High solids content | 2-8% suspended solids in RAS | Clogs mechanical meters, fouls differential pressure taps |

| Abrasive particles | Grit, sand, biological filaments | Rapid wear on moving parts, electrode damage |

| Signal noise | Particles impacting electrodes | Millivolt spikes interpreted as false flow readings |

The Hidden Cost: Signal Instability

Here’s something most equipment vendors won’t tell you: even when a magnetic flow meter is installed correctly, slurry noise can destabilize your readings.

Based on our field experience troubleshooting WWTP installations, we’ve observed that entrained debris creates millivolt spikes when particles impact the electrode sensors. Standard mag meters struggle to separate these noise signals from actual flow signals consistently.

The traditional workaround? Operators extend the damping time to 30-60 seconds. But this kills real-time control—when your process deadtime is under one second, you’re essentially flying blind with stale data.

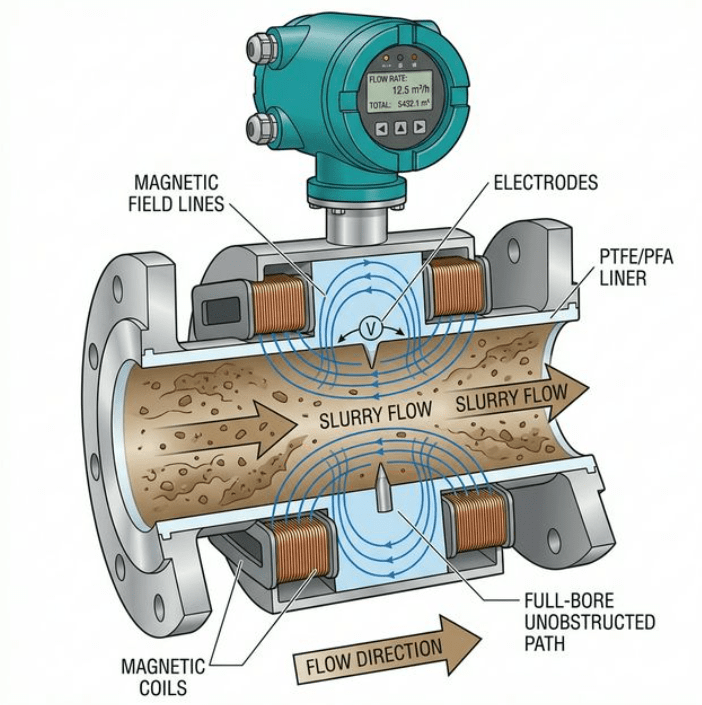

How Magnetic Flow Meters Work

Understanding why mag meters dominate slurry applications starts with the physics:

Faraday’s Law of Electromagnetic Induction

Magnetic flow meters operate based on a beautifully simple principle discovered by Michael Faraday in 1831:

E = B × D × V

Where:

- E = Induced voltage (mV)

- B = Magnetic field strength

- D = Pipe diameter

- V = Fluid velocity

When a conductive fluid (like wastewater or sludge) flows through a magnetic field, it acts as a moving conductor, generating a voltage directly proportional to flow velocity. As the fluid flows through the flow tube, electrodes mounted on opposite sides detect this induced voltage.

Why This Matters for Slurry Applications

The key advantage: there are no moving parts, no internal obstructions, and no impulse lines that can clog. The meter measures volumetric flow rate purely through electromagnetic induction—the sludge particles are irrelevant to the measurement principle (as long as the carrier liquid is conductive).

| Traditional Meter | Magnetic Flow Meter |

|---|---|

| ❌ Orifice plates collect debris | ✅ Full-bore, unobstructed path |

| ❌ Turbine bearings wear out | ✅ No moving parts |

| ❌ Positive displacement seals fail | ✅ No mechanical contact |

| ❌ Ultrasonic struggles with particles | ✅ Particles don’t affect signal |

Why Mag Meters Dominate Slurry Applications

After installing electromagnetic flow meters in mining operations, paper mills, and wastewater treatment plants, we’ve identified the core reasons for their dominance:

1. Obstruction-Free Design

Unlike differential pressure meters (Venturi, orifice plates) that depend on flow restrictions, mag meters present the same internal diameter as the adjacent pipe. Nothing for solids to accumulate on. Nothing to erode.

2. Wide Range of Liner & Electrode Materials

Slurries aren’t all the same. Mining slurry differs vastly from wastewater sludge. Modern electromagnetic flow meters offer material combinations to match:

| Application | Recommended Liner | Recommended Electrodes |

|---|---|---|

| Wastewater RAS/WAS | PTFE or F46 | Stainless Steel 316L |

| Paper pulp (EPA process wastewater) | F46 or PFA | Hastelloy C |

| Mining slurry (highly abrasive) | PFA (reinforced) | Stainless Steel Coated Tungsten Carbide |

| Chemical slurry (corrosive) | PTFE or PFA | Titanium or Tantalum |

Per our company product catalog, our electromagnetic flow meters offer:

- Liner materials: PTFE, F46, PFA

- Electrode materials: SUS316, Hastelloy B, Hastelloy C, Titanium, Stainless Steel Coated Tungsten Carbide, Tantalum, Platinum

- Accuracy: ±0.5% standard (±0.3% or ±0.2% optional)

- Pressure rating: Up to 42 MPa (pipeline type max pressure)

3. Advanced Signal Processing

The latest generation of mag meter transmitters addresses the noise problem directly. Rather than excessive damping (which delays your control response), advanced signal processing algorithms can:

- Separate particle-impact noise from true flow signals

- Provide stable readings without sacrificing responsiveness

- Enable closed-loop automatic control even in noisy slurry environments

Electromagnetic Flow Meter Technical Specifications

Based on our product catalog, here are the key specifications for slurry service:

Standard Pipeline Electromagnetic Flow Meter

| Parameter | Specification |

|---|---|

| Applicable Media | Conductive liquid (including slurry) |

| Accuracy | ±0.5% standard; ±0.3% or ±0.2% optional (high-pressure type) |

| Pipe Diameter Range | DN3-DN3000 |

| Velocity Range | 0.1-15 m/s |

| Temperature Range | -40°C to +180°C (medium) |

| Working Pressure | 42 MPa max (pipeline type); 4.0 MPa max (insertion type) |

| Conductivity Requirement | ≥20 µS/cm |

| Turndown Ratio | 150:1 (wide range capability) |

| Protection Class | IP65, IP68 |

| Output | 4-20mA, RS-485/HART, pulse/frequency |

Key Features for Slurry Applications

✅ No moving parts in measuring tube – zero clogging risk

✅ No pressure loss – critical for gravity-fed sludge lines

✅ Bi-directional measurement – handles RAS/WAS return flows

✅ Empty pipe detection – alarm when pipe runs dry

✅ Batch control capability – dosing applications

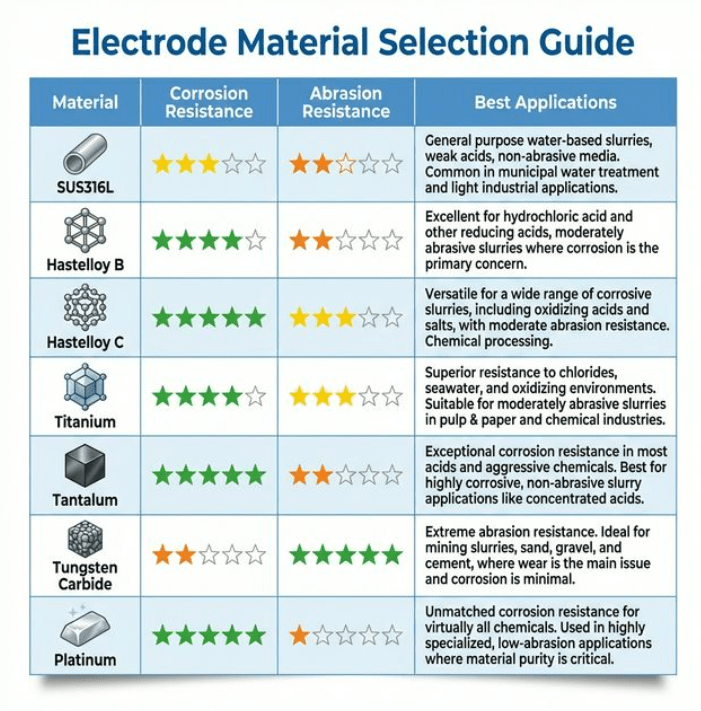

Material Selection: Liner & Electrode Choices

Choosing the right materials is critical. Make the wrong choice in abrasive slurry service, and you’ll be replacing your meter within months.

Liner Material Selection Guide

Based on our product catalog, available liner materials are PTFE, F46, and PFA:

| Liner | Temperature Range | Best For | Considerations |

|---|---|---|---|

| PTFE | -10°C to +160°C | Chemical slurry, food-grade | Excellent chemical resistance |

| F46 | -10°C to +160°C | General industrial slurry | Good balance of properties |

| PFA | -10°C to +160°C | High-purity, pharmaceutical | Premium corrosion resistance |

Note: Temperature range based on high-pressure type specifications from our product catalog.

Electrode Material Selection Chart

| Electrode Material | Corrosion Resistance | Abrasion Resistance | Typical Applications |

|---|---|---|---|

| SUS316L | ★★★☆☆ | ★★☆☆☆ | General wastewater, mild slurry |

| Hastelloy B (HB) | ★★★★★ | ★★★☆☆ | Strong acids, HCl |

| Hastelloy C (HC) | ★★★★★ | ★★★☆☆ | Oxidizing acids, chlorine |

| Titanium | ★★★★☆ | ★★★☆☆ | Seawater, chloride solutions |

| Tantalum | ★★★★★ | ★★★☆☆ | Highly corrosive acids |

| SS Coated Tungsten Carbide | ★★★☆☆ | ★★★★★ | Highly abrasive slurries |

| Platinum | ★★★★★ | ★★★☆☆ | Special high-purity applications |

Installation Best Practices for Slurry Service

Even the best mag meter will underperform if installed incorrectly. Here’s what we’ve learned from hundreds of installations:

Critical Flow Velocity Window

For slurry applications, the operating velocity is your most important installation parameter. According to standard slurry pipeline design practices, maintaining proper velocity prevents both settling and excessive wear:

| Velocity Range | Effect |

|---|---|

| < 1.5 ft/sec (0.45 m/s) | ⚠️ Solids settle in pipe – inaccurate readings |

| 1.5-6 ft/sec (0.45-1.8 m/s) | ✅ Optimal range – solids suspended, minimal wear |

| > 6 ft/sec (1.8 m/s) | ⚠️ Accelerated abrasion – shorter liner life |

Pro tip: In abrasive slurry service, always size for the lower end of the velocity window—even if it means slight accuracy trade-offs—to maximize liner lifespan.

Grounding Requirements

Proper grounding isn’t optional for mag meters. Poor grounding is the #1 cause of erratic readings we encounter during troubleshooting.

- Install grounding rings on both flanges for non-conductive pipe (PVC, HDPE)

- Connect grounding rings directly to meter grounding terminals

- Verify grounding continuity with a multimeter before commissioning

For detailed guidance, see our guide: Why Does A Magnetic Flow Meter Need Grounding?

Installation Orientation

| Orientation | Recommendation |

|---|---|

| Horizontal | ✅ Preferred – electrodes at 3 and 9 o’clock |

| Vertical (up-flow) | ✅ Acceptable – ensures full pipe |

| Vertical (down-flow) | ❌ Avoid – risk of empty pipe conditions |

Troubleshooting Common Slurry Issues

Even well-designed installations can experience problems. Here’s our field-tested troubleshooting guide:

| Problem | Possible Cause | Solution |

|---|---|---|

| Erratic readings | Electrode coating/fouling | Clean electrodes; consider anti-fouling electrodes |

| Signal drops to zero | Air bubbles in pipe | Install at lowest point; add back pressure |

| Readings drift over time | Liner wear from abrasion | Inspect liner; switch to ceramic lining |

| Noise-induced spikes | Particle impingement | Increase damping (cautiously); upgrade transmitter signal processing |

| Zero offset | Improper grounding | Verify ground connections; add grounding rings |

| Negative flow readings | Reverse flow or wiring error | Check wiring polarity; verify process direction |

Case Study: Return Activated Sludge at Municipal WWTP

One of our most successful installations was at a 100,000 m³/day municipal wastewater treatment plant in Jiangsu Province:

The Challenge

- Previous Venturi-based RAS measurement required monthly cleaning

- Operators had zero confidence in flow data

- Process control was essentially manual

Our Solution

- Installed DN300 electromagnetic flow meter with hard rubber liner and 316L electrodes

- Configured for 2-second damping (vs. their previous 45-second workaround)

- Integrated 4-20mA output directly into SCADA system

The Results

| Metric | Before | After |

|---|---|---|

| Maintenance frequency | Monthly de-clogging | Zero in 18 months |

| Reading stability | ±15% variation | <±2% variation |

| Operator intervention | Constant manual adjustment | Automatic closed-loop control |

| Measurement confidence | Low | High |

"We finally trust our RAS flow data. The savings in operator time alone justify the investment." — Plant Operations Manager

Frequently Asked Questions

Can magnetic flow meters measure all types of slurries?

Magnetic flow meters can measure any slurry with a conductive carrier liquid (minimum conductivity ≥20 µS/cm). This includes most water-based slurries found in wastewater treatment, mining, and paper production. However, mag meters cannot measure slurries in non-conductive carrier fluids like hydrocarbons or pure oils.

How does slurry concentration affect accuracy?

For most applications with up to 30-40% solids by volume, accuracy remains within specification. At extremely high concentrations, the effective pipe diameter may change slightly, introducing minor errors. However, the impact is typically negligible compared to the massive inaccuracies seen with mechanical meters in the same conditions.

What’s the lifespan of a mag meter in slurry service?

With proper material selection and installation, magnetic flow meters routinely achieve 10-15+ years of service life in slurry applications—far exceeding mechanical alternatives. The key is matching your liner and electrode materials to your specific slurry characteristics.

Why can’t I use ultrasonic flow meters for sludge?

Transit-time ultrasonic meters require clean fluid paths for the acoustic signal to propagate. High solids content scatters and attenuates the ultrasonic signal, causing measurement failures. While Doppler ultrasonic meters can work with some slurries, they generally offer lower accuracy than magnetic flow meters and struggle with homogeneous slurries.

Do mag meters cause pressure drop in the system?

No. Because magnetic flow meters have a full-bore, obstruction-free design, they cause essentially zero pressure drop—no more than an equivalent length of straight pipe. This is critical for gravity-fed sludge systems where any restriction can back up the process.

How often should I calibrate a mag meter in slurry service?

For critical wastewater applications, we recommend annual verification using your transmitter’s diagnostic functions. Full wet calibration is typically needed only every 2-3 years unless regulations require more frequent checks.

Conclusion

For measuring sludge and slurry flows, magnetic flow meters offer an unmatched combination of:

- ✅ Zero clogging risk – no internal obstructions

- ✅ Long service life – no wearing mechanical parts

- ✅ Accurate measurement – ±0.5% even with high solids content

- ✅ Zero pressure drop – critical for gravity systems

- ✅ Wide material options – match your specific slurry chemistry and abrasiveness

Whether you’re measuring return activated sludge in a WWTP, ore slurry in a mining operation, or pulp stock in a paper mill, electromagnetic flow meters deliver the reliable, maintenance-free performance that enables true process control.

Ready to Solve Your Slurry Measurement Challenges?

Contact our flow measurement experts for personalized recommendations based on your specific sludge or slurry application:

🔍 View Our Electromagnetic Flow Meter Products

Related Articles

- What Is The Best Flow Meter For Sludge?

- What Is An Electromagnetic Flow Meter For Wastewater?

- Why EMFs Are the Unsung Heroes of WWTPs

- Can Electromagnetic Flow Meters Handle Corrosive or Abrasive Fluids?

- How Electromagnetic Flow Meters Improve Efficiency in Wastewater Treatment

Published by Soaring Instrument | Shanghai, China