Did you know 37% of electromagnetic flow meter failures stem from temperature and contamination issues? Here’s how to prevent them.

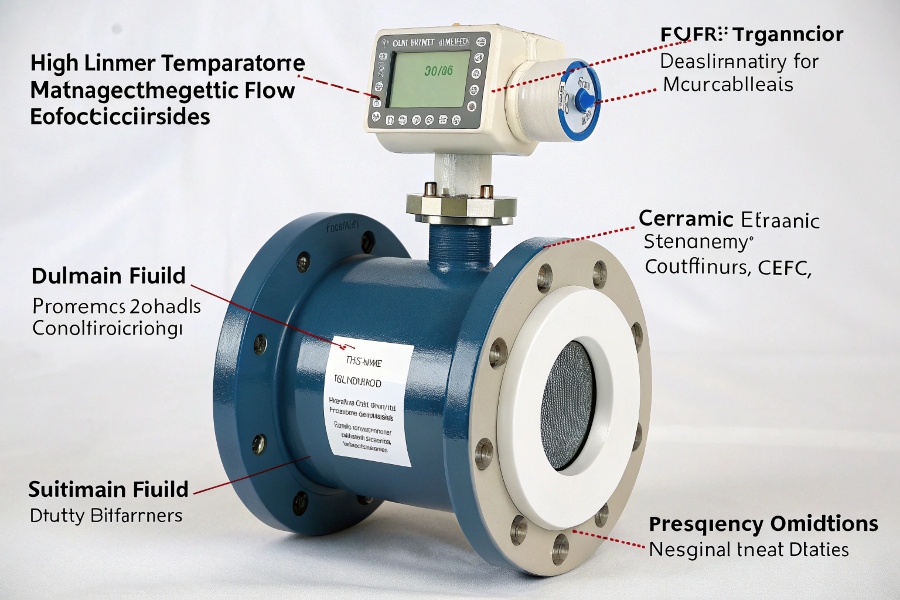

Standard EMFs handle 0-60°C, while high-temp versions withstand 180°C using PFA liners and ceramic electrodes. For dirty fluids, dual-frequency excitation (1/25Hz) maintains ±0.5% accuracy despite solids/bubbles, and polyurethane liners resist abrasion 5× better than standard PTFE in slurry applications.

Temperature-Resistant EMF Design

What Is the Effect of Temperature on Flow Measurement?

Temperature impacts every measurement component.

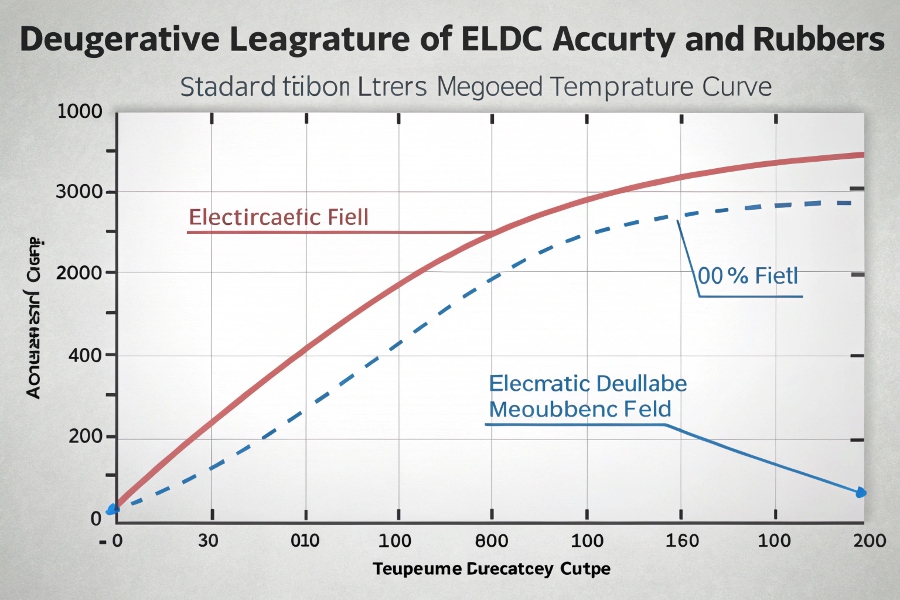

Above 80°C, standard rubber liners degrade (swelling 2-3%), electrode seals leak, and magnetic field strength drops 0.1%/°C. Specialized EMFs use ceramic insulation (withstanding 200°C) and pulsed-DC excitation to compensate for temperature-induced conductivity changes in fluids (±0.05%/°C stability).

Accuracy vs Temperature

Temperature thresholds by component:

EMF Component Temperature Limits

| Component | Standard Grade | High-Temp Option |

|---|---|---|

| Liner Material | EPDM (80°C) | PFA (180°C) |

| Electrodes | 316SS (100°C) | Ceramic (200°C) |

| Seals | Nitrile (90°C) | Kalrez (200°C) |

| Electronics | -40-60°C | -40-85°C |

| Cable | PVC (70°C) | PTFE (260°C) |

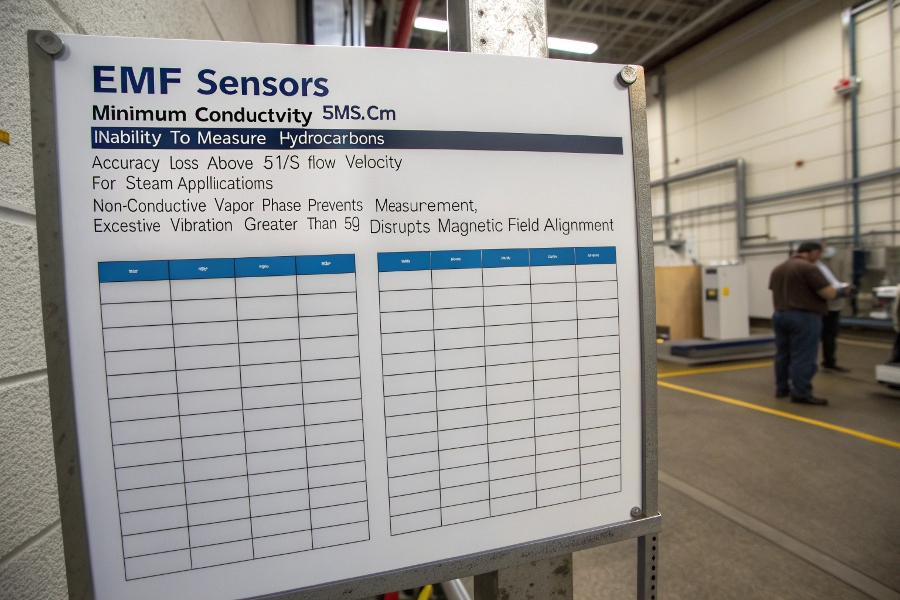

What Are the Limitations of an Electromagnetic Flow Meter?

Three critical constraints demand attention.

EMFs require minimum conductivity (5μS/cm), can’t measure hydrocarbons, and suffer accuracy loss above 5m/s flow velocity. For steam applications, the non-conductive vapor phase prevents measurement, while excessive vibration (>5g) disrupts the magnetic field alignment needed for precise readings.

Operating Boundaries

Overcoming common constraints:

EMF Limitation Workarounds

Low Conductivity Fluids

- Add tracer ions (cost: $0.02/m³)

- Switch to annular electrode design

High Solids Content

- Use wear-resistant polyurethane liners

- Install ground rings to stabilize signal

Pulsating Flow

- Add damping setting (0.5-10s adjustable)

- Install pulsation dampeners1

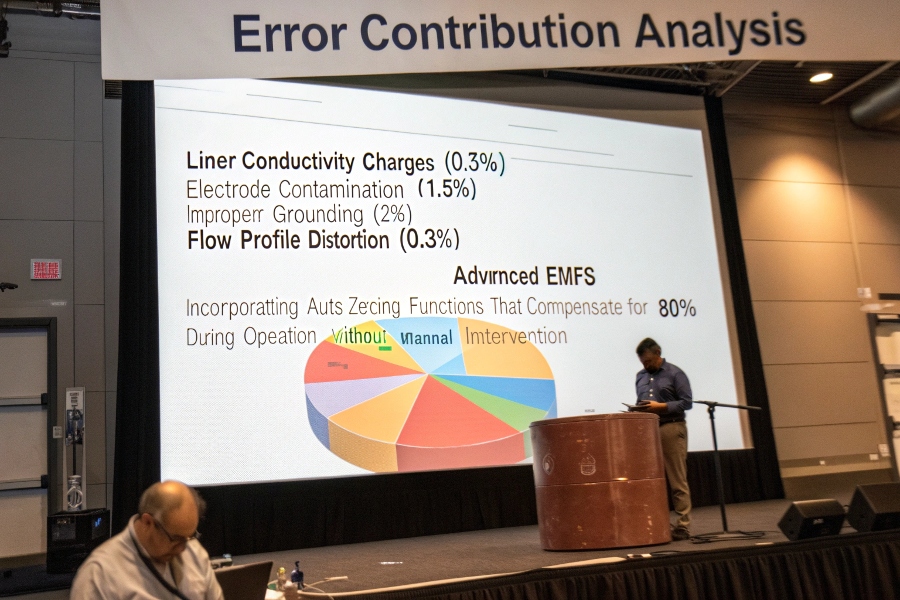

What Are the Major Factors Affecting Flow Measurement Errors?

Eight variables cause 92% of accuracy issues.

Top error sources include: liner conductivity changes2 (±0.3% error), electrode contamination3 (±1.5%), improper grounding (±2%), and flow profile distortion (±0.8%). Advanced EMFs now incorporate auto-zeroing functions that compensate for 80% of these errors during operation without manual intervention.

Error Contribution Analysis

Quantifying error contributors:

EMF Error Factors & Remedies

| Error Source | Typical Impact | Correction Method |

|---|---|---|

| Electrode Fouling | +1.0 to -1.5% | Ultrasonic cleaning |

| Liner Wear | ±0.5%/year | Ceramic-lined models |

| Temperature Swing | ±0.2%/10°C | PT100 compensation |

| Flow Profile | ±0.8% | 10D straight pipe |

| Ground Loops | ±2.0% | Isolated converters |

| Bubbles/Solids | ±1.2% | Dual-frequency mode |

| Vibration | ±0.5% | Shock-mounted sensors |

| Cable Length | ±0.3%/100m | Signal conditioners |

What Different Fluids Can Be Measured Using Electromagnetic Flow Meters?

From acids to slurry – if it conducts, EMFs measure it.

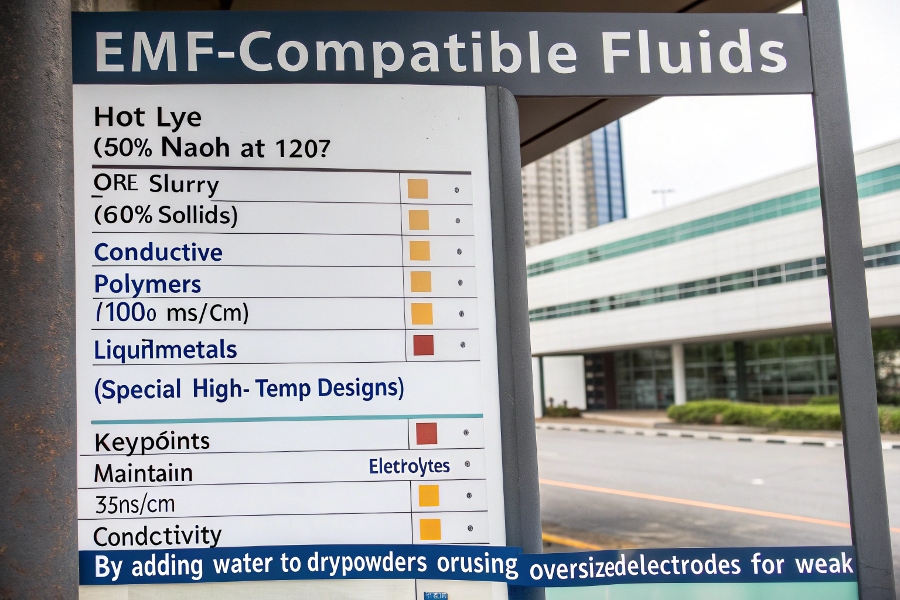

Valid applications include: hot lye (50% NaOH at 120°C), ore slurry (60% solids), conductive polymers (>100μS/cm), and even liquid metals (special high-temp designs). The key is maintaining >5μS/cm conductivity – achieved by adding water to dry powders or using oversized electrodes for weak electrolytes.

EMF-Compatible Fluids

Fluid-specific solutions:

Challenging Fluid Measurement Approaches

| Fluid Type | Challenge | EMF Solution |

|---|---|---|

| Acid Pickling | High corrosion | Tantalum electrodes |

| Paper Stock | Fiber buildup | High-velocity flush ports |

| Coal Slurry | Extreme abrasion | Tungsten carbide liners |

| Milk of Lime | Coating formation | 25Hz excitation frequency |

| Molten Sulfur | 140°C+ temps | Ceramic sensor heads |

| RO Water | Low conductivity | Annular electrode design |

Installation Checklist for Harsh Services

Ensure reliable operation with these steps:

Temperature Verification

- Confirm fluid temp ≤90% of liner rating

- Insulate pipes >120°C

Contamination Prevention

- Install upstream strainers for >5% solids

- Specify flush connections for sticky fluids

Electrical Protection

- Use waterproof (IP68) junction boxes

- Install lightning arrestors outdoors

Mechanical Safeguards

- Vibration isolation for >2g environments

- Expansion joints for steam tracing lines

Conclusion

Modern EMFs conquer extreme conditions through specialized materials and smart compensation—delivering dependable flow measurement where other technologies fail, even in 180°C fluids with 60% solids content.

Learning about pulsation dampeners can provide insights into optimizing flow measurement systems and improving overall performance. ↩

Understanding liner conductivity changes is crucial for improving flow measurement accuracy and reducing errors in various applications. ↩

Exploring the effects of electrode contamination can help in implementing better maintenance practices to enhance measurement reliability. ↩