Flow measurement fails when pipes aren’t full. But why does this happen, and what are your alternatives?

EMFs require full pipe conditions to work accurately because they measure voltage induced across the liquid’s cross-sectional area. When pipes aren’t full, the signal corresponds only to the wetted electrode portion, causing 30-50% errors. Only specially designed "partial-full" EMFs with multiple electrodes can handle this challenge.

Full vs Partial Pipe Flow

Let’s explore why traditional EMFs fail in this application and what solutions exist.

What Are the Limitations of an Electromagnetic Flow Meter?

Understanding EMF limitations prevents costly measurement mistakes.

Key limitations include: full pipe requirement, minimum conductivity (5 µS/cm), straight run needs (5-10 pipe diameters), and sensitivity to air bubbles. They also can’t measure hydrocarbons or gases, and require grounding in plastic pipes.

EMF Limitation Factors

These constraints stem from fundamental working principles:

Physical Constraints of EMFs

| Limitation | Technical Reason | Workaround |

|---|---|---|

| Non-full pipe | Measures cross-section area | Use partial full EMF |

| Low conductivity | Needs current flow | Add electrolytes |

| Gas bubbles | Distort field geometry | Venturi installation |

| Pulsating flow | Affects signal stability | Dampener chamber |

| Coatings | Insulate electrodes | Cleaner rings |

How Accurate Is an Insertion Flow Meter?

Point measurement comes with tradeoffs.

Insertion meters typically offer ±2-5% accuracy vs ±0.5% for full-bore EMFs. Their error increases in turbulent or asymmetric flows since they sample at just one point. However, they work in partially full pipes and large diameters where EMFs can’t.

Insertion Probe Installation

Understanding their advantages helps proper selection:

When to Choose Insertion Meters

| Situation | Advantage Over EMF | Accuracy Note |

|---|---|---|

| Pipe >300mm | Cost-effective | ±5% in turbulent flow |

| Partial fill | Works down to 20% depth | Needs stable flow profile |

| Temporary install | Portable options exist | Requires calibration |

| Slurry flows | Less affected by solids | Wear changes calibration |

| High temp gas | Some models handle 400°C | Thermal expansion affects |

How Can I Measure Flow Without a Flow Meter?

Alternative methods exist when conventional meters won’t work.

Three practical methods: 1) Tank level monitoring (±5% with proper strapping), 2) Pump curves with pressure readings (±10-15%), 3) Ultrasonic transit time (±3% with long straight runs). All require stable process conditions.

Non-Meter Flow Methods

These approaches work in difficult situations:

Alternative Measurement Techniques

Tank Weighing

- Load cells measure mass directly

- Needs density correction for volume

- ±1% possible with calibration

Pump Characteristic Method

- Flow correlates with pressure drop

- Requires constant pump speed

- Viscosity changes affect accuracy

Ultrasonic Velocity

- Clamp-on sensors measure Vavg

- Needs 10D upstream straight pipe

- Limited in slurries

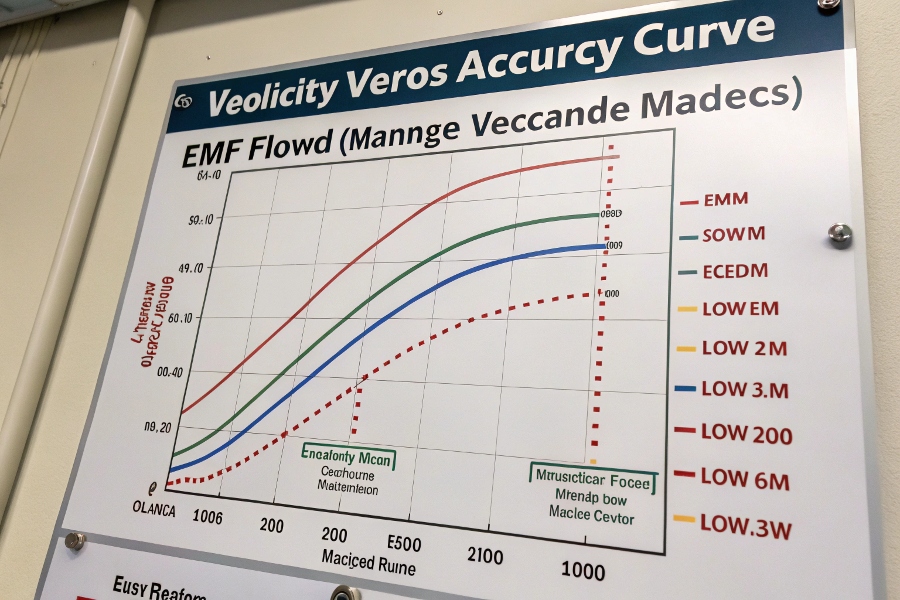

What Is the Flow Range of Electromagnetic Flow Meter?

EMFs handle impressive flow spans with limitations.

Standard EMFs measure 0.3-10 m/s velocity (0.1-12,000 m³/h pipe-size dependent). Low-flow models extend to 0.1 m/s. The turndown ratio reaches 1000:1 in high-end meters, but 100:1 is more typical for industrial models.

Velocity vs Accuracy Curve

Understanding range capabilities ensures proper sizing:

EMF Sizing Considerations

| Pipe Size | Minimum Flow (m³/h) | Maximum Flow (m³/h) | Notes |

|---|---|---|---|

| DN15 | 0.1 | 10 | Noise issues at low end |

| DN50 | 2.5 | 100 | Optimal accuracy range |

| DN100 | 10 | 400 | Standard industrial use |

| DN300 | 90 | 3600 | Check upper velocity limit |

| DN600 | 350 | 15000 | Verify grounding possible |

Partial-Full EMF Solutions

Special designs overcome traditional limits.

New multi-electrode EMFs using tomography principles can handle 10-100% fill levels (±2% accuracy). These install like standard EMFs but cost 3-5× more. They work well in wastewater and mining applications with variable flows.

Partial-Full EMF Design

Key players offer different approaches:

Partial-Full EMF Technologies

Array Electrodes (6-16 points)

- Maps wetted perimeter

- Handles asymmetrical flow

- Needs clean electrodes

Field-Focusing Design

- Concentrates field in liquid

- Less affected by air interface

- Limited to 30% minimum fill

Hybrid Ultrasonic-EMF

- Ultrasonic measures fill level

- Combines with EMF velocity

- Most expensive option

Installation Best Practices

Proper setup maximizes accuracy.

Orientation Matters

- Horizontal installs need top electrodes clean

- Vertical flows should be upward

Grounding Solutions

- Ground rings for lined pipe

- Dedicated ground electrode

Air Elimination

- Vent valves at high points

- Downward elbows prevent gas traps

Conclusion

While traditional EMFs can’t accurately measure partially full pipes, new multi-electrode designs overcome this limitation at higher cost. Insertion meters offer alternative solutions for large pipes, and non-meter methods work for approximate measurements. Always verify minimum flow requirements and consider future process changes when selecting equipment – the extra investment in flexible technology often pays off in long-term reliability.