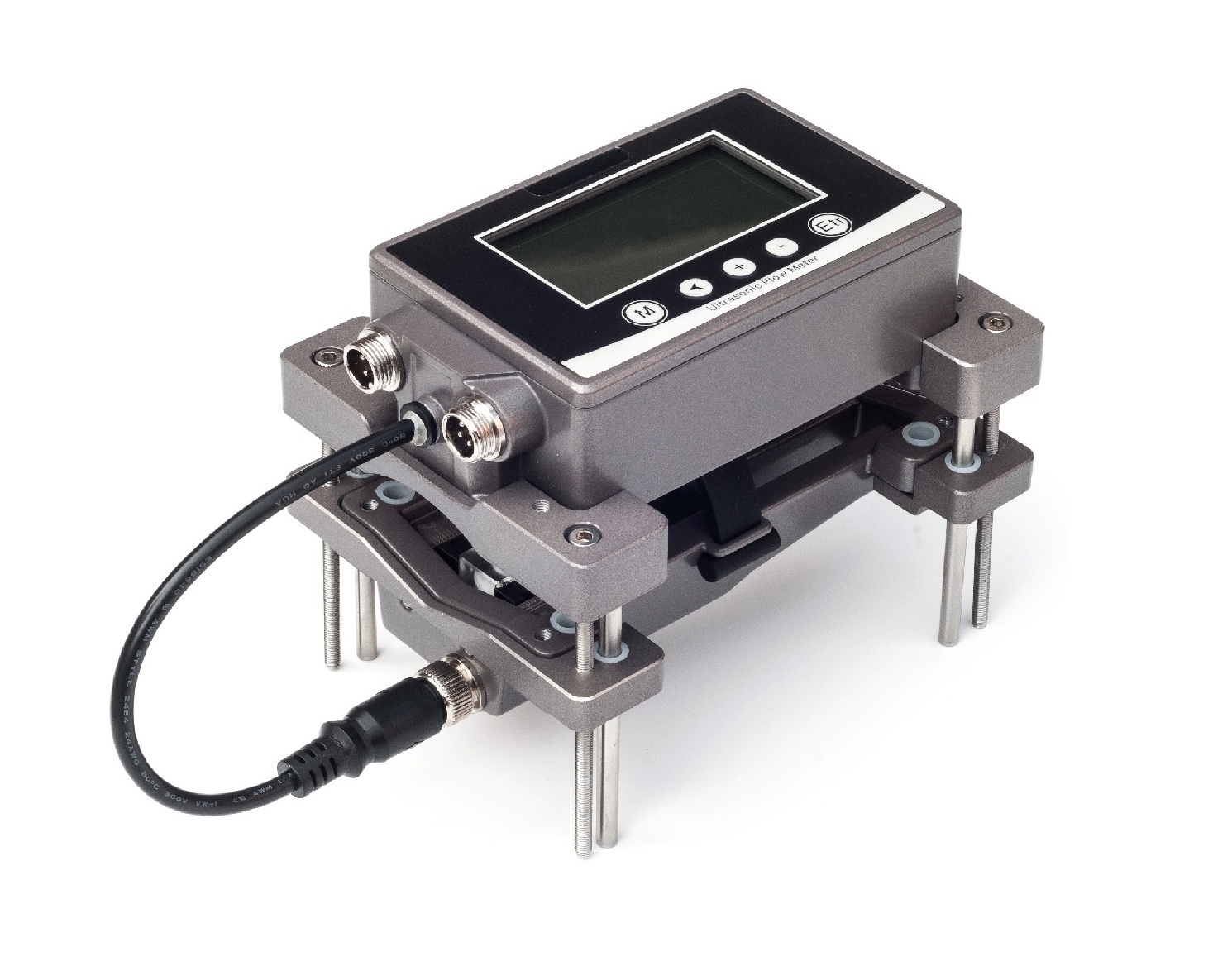

Struggling to measure flow accurately in narrow pipelines? Small diameter pipes present unique challenges for ultrasonic flow measurement that demand specialized solutions. Traditional clamp-on models often fail below DN25 sizes.

Ultrasonic flow meters for small pipes (DN8-DN25) require focused beam paths, high-frequency transducers (1MHz+), and specialized signal processing. In-line wetted designs typically outperform clamp-on models below DN25, achieving ±1% accuracy when properly installed. Selection depends on fluid properties and pipe material.

Ultrasonic Measurement in Narrow Pipes

While powerful for mid-size pipes, ultrasonic technology faces distinct limitations in cramped spaces. Here’s how to overcome them.

What Are the Limitations of an Ultrasonic Flow Meter in Small Pipes?

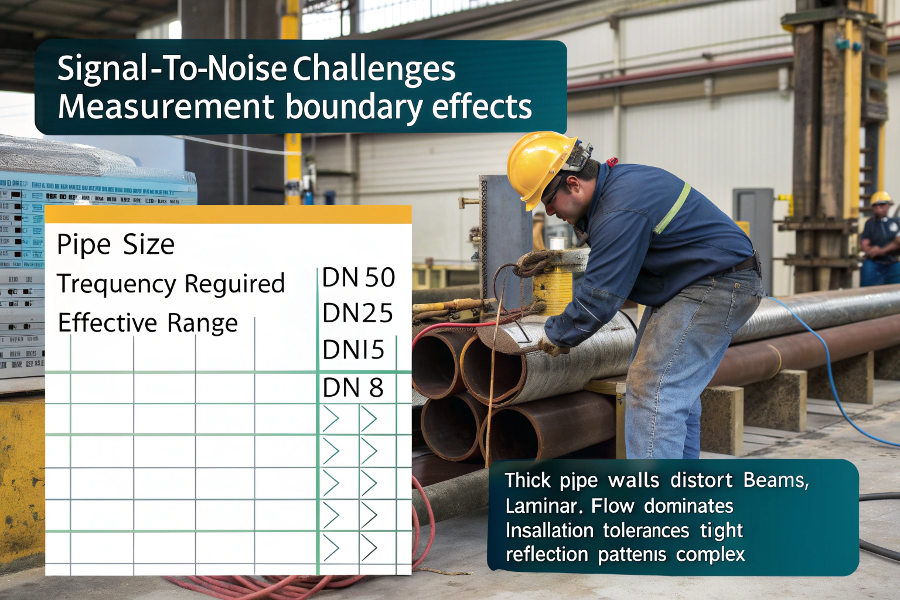

Critical constraints below DN25:

Signal-to-Noise Challenges

| Pipe Size | Frequency Required | Effective Range |

|---|---|---|

| DN50 | 500kHz | 3-5m |

| DN25 | 1MHz | 1-2m |

| DN15 | 2MHz | 0.5-1m |

| DN8 | 5MHz | <0.3m |

Measurement Boundary Effects

- Thick pipe walls distort beams

- Laminar flow dominates

- Installation tolerances tighten

- Reflection patterns complex

Small Pipe Limitations

Practical Workarounds

- Inline transducers: Eliminate wall effects

- Multiple reflections: Increase path length

- Specialized algorithms: Compensate for distortion

- High-precisioin machining: Ensure perfect alignment

How Many Pipe Diameters for Proper Flow Meter Installation?

Flow profile requirements by technology:

Upstream/Downstream Straight Run Needs

| Condition | Clamp-On Needs | Inline Needs |

|---|---|---|

| Single elbow | 15D/5D | 10D/5D |

| Double elbow | 30D/5D | 20D/5D |

| Pump discharge | 50D/10D | 30D/10D |

| Control valve | 30D/10D | 20D/10D |

Small Pipe Exceptions

- Below DN25: Add 50% more length

- High viscosity: Double requirements

- Non-Newtonian fluids: Case specific

Installation Tips for Tight Spaces

- Use flow conditioners

- Install in vertical rises

- Multiple measurement paths

- Electronic profile compensation

What Is the Straight Length Requirement for Ultrasonic Flow Meters?

Minimum distances before/after the meter:

Standard Requirements

| Pipe Size | Minimum Upstream | Minimum Downstream |

|---|---|---|

| DN8-DN15 | 25D | 10D |

| DN20-DN40 | 15D | 5D |

| DN50+ | 10D | 5D |

Reducing Straight-Run Needs

- Multi-path designs: 30% less needed

- Integrated conditioners: Halve requirements

- Advanced DSP: Compensate for disturbances

- Cross-correlation tech: Handle poor profiles

Straight-Run Requirements

When You Can’t Meet Requirements

- Calibrate at actual conditions

- Use diagnostic algorithms

- Install temporary strainers

- Consider alternate technologies

What Type of Ultrasonic Flow Meter Is Best for Clean Fluids?

Optimal configurations for bubble/slurry-free liquids:

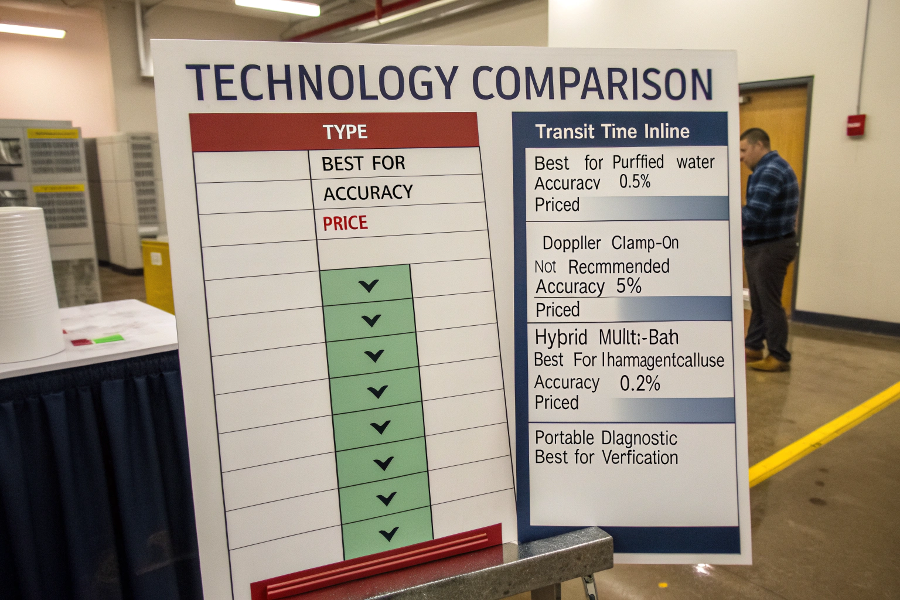

Technology Comparison

| Type | Best For | Accuracy | Price |

|---|---|---|---|

| Transit-time inline | Purified water | ±0.5% | $$$$ |

| Doppler clamp-on | Not recommended | ±5% | $ |

| Hybrid multi-path | Pharmaceutical | ±0.2% | $$$$$ |

| Portable diagnostic | Verification | ±1% | $$ |

Clean Fluid Specialization

- High-frequency focus: 2-5MHz transducers

- Precision machined bodies: Minimize disturbance

- Reflective targets: Internal enhancements

- Low-power operation: Prevent heating

Clean Fluid Solutions

Top Applications

- DI water systems

- Solvent processing

- Beverage production

- Petrochemicals

- Precision cooling

Conclusion

Ultrasonic flow measurement in small pipes demands high-frequency (1-5MHz) transducers, precision installation, and specialized signal processing. While standard clamp-on meters struggle below DN25, dedicated inline ultrasonic flow meters can achieve ±1% accuracy in pipes as small as DN8 when optimized for clean fluids. Always verify straight-pipe requirements (typically 25D upstream for small pipes) and consider wetted transducer designs for the most reliable small-diameter measurements. For critical clean fluid applications, multi-path transit-time meters with advanced DSP provide the ultimate in accuracy despite space constraints.