level switch

A level switch is a device used to detect and monitor the level of a liquid or solid within a container or vessel. It is designed to trigger an action (such as turning a pump on or off, or sending an alert) when the material reaches a predetermined level.

RF Admitance level switch (liquid)

Single Rod Vibrating Level Switch

Tuning Fork Level Switch

(Liquid)

large tuning fork level switch (liquid)

small tuning fork level switch (liquid)

small rotary paddle level switch

totary paddle level switch

square rotary paddle level switch

All You Need to know About level switch

What is tuning fork level switch?

A tuning fork level switch is a type of level detection device that uses the principle of mechanical vibration to detect the presence or absence of a material (liquid, powder, or granular solid) at a specific point in a container or vessel. It is widely used in industrial applications due to its reliability, accuracy, and ability to work in harsh conditions.

Applications:

- Liquid Level Control: In tanks, pipelines, or reactors.

- Powder or Granular Solids: In silos, hoppers, or bins.

- Industry Use: Food and beverage, chemical, pharmaceutical, water treatment, and oil and gas industries.

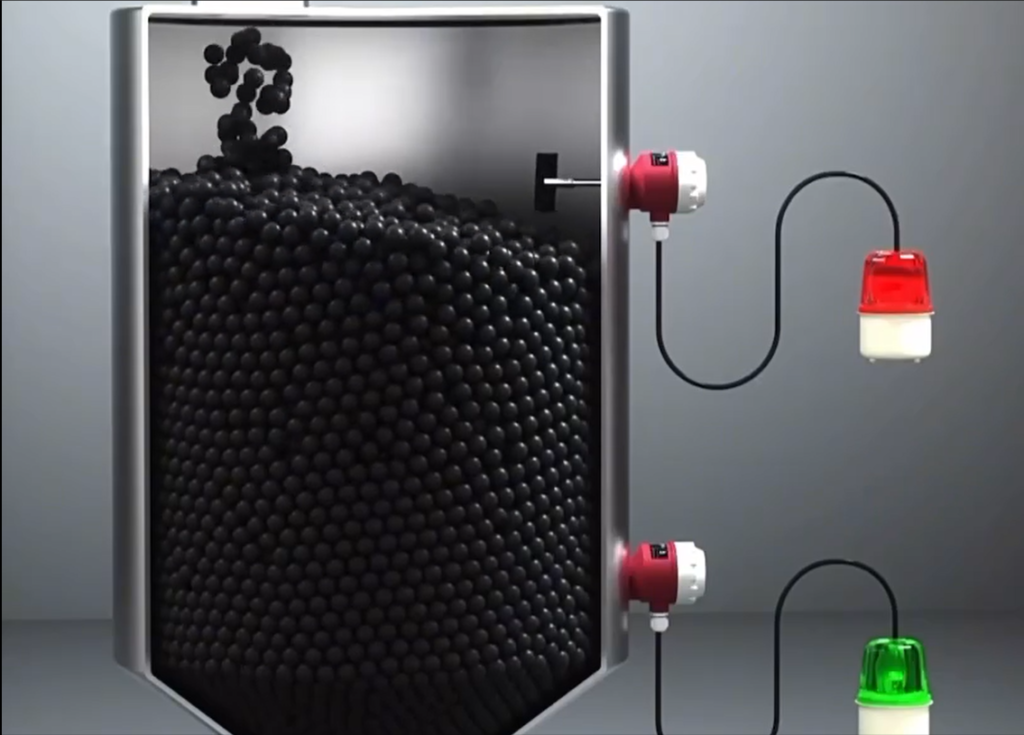

What is rotary paddle level switch?

A rotary paddle level switch is an instrument used for detecting the level of bulk solid materials (e.g., powders, granules, or pellets) in silos, bins, or hoppers. It operates based on the principle of mechanical rotation and resistance, making it a reliable solution for point-level detection in industrial applications.

Applications:

- Silos and Hoppers: Detecting high or low levels of bulk solids.

- Conveyor Systems: Monitoring material flow in processing lines.

- Feed Systems: Ensuring continuous supply of material in production.

- Industry Use: Agriculture, chemical, food processing, cement, and recycling industries.

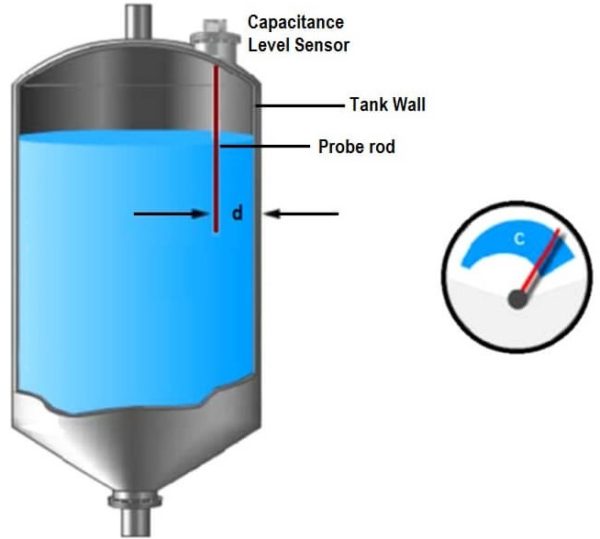

what is RF admittance level switch?

An RF admittance level switch (also known as a capacitance level switch) is an advanced level detection device that uses the principle of radio frequency (RF) admittance or capacitance to detect the presence or absence of a material (liquid, powder, or granular solid) at a specific point in a container or vessel. It is highly accurate and versatile, making it suitable for a wide range of industrial applications.

Application:

- Liquid Level Control: In tanks, reactors, or pipelines.

- Powder or Granular Solids: In silos, bins, or hoppers.

- Industry Use: Chemical, pharmaceutical, food and beverage, oil and gas, water treatment, and more.

- Interface Detection: Can detect the interface between two liquids (e.g., oil and water)

Production Process