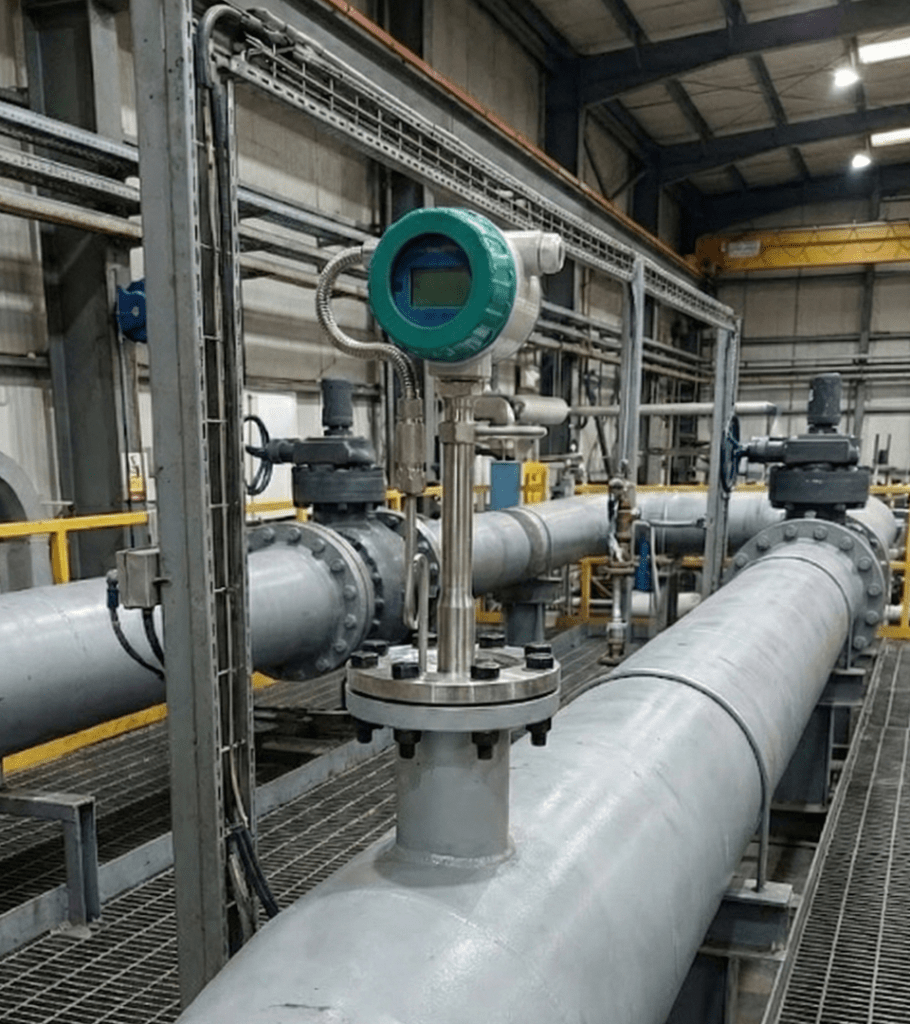

When a paper mill asked us to quote flow meters for their DN400 steam line, they expected to pay $15,000+ for a full-bore inline vortex meter. We proposed an insertion vortex flow meter instead — at less than half the cost, with comparable accuracy.

This is the reality for large pipe applications: insertion vortex flow meters offer a dramatically lower total cost of ownership while maintaining ±1.5% to ±2.5% accuracy. In our 15+ years of flow measurement experience, we’ve seen insertion meters become the go-to solution for pipes DN200 and larger.

Quick Answer: An insertion vortex flow meter installs through a single pipe penetration rather than replacing an entire pipe section. This reduces equipment cost by 40-60%, eliminates cutting large pipes, and enables hot-tap installation and commissioning without shutting down the process. It’s ideal for measuring steam, gas, and liquid in pipes DN200 (8") and larger.

What Is an Insertion Vortex Flow Meter?

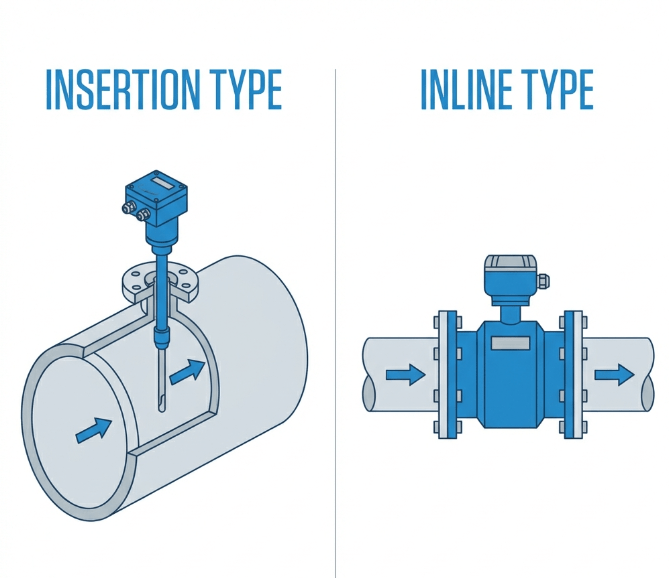

An insertion vortex flow meter consists of a vortex-shedding sensor mounted on a probe that inserts into the pipe through a single connection point. Unlike inline (full-bore) vortex flow meters that replace a pipe section, insertion meters sample the flow at a specific point in the pipe cross-section.

Insertion vs. Inline: Key Differences

| Feature | Insertion Vortex | Inline Vortex |

|---|---|---|

| Installation | Single pipe penetration | Cut pipe, install flanges |

| Pipe Size Range | DN80 – DN2000+ | DN15 – DN300 |

| Meter Cost | 40-60% lower for large pipes | Higher for DN200+ |

| Installation Cost | Much lower (no pipe cutting) | Higher (welding, flanges) |

| Hot-Tap Capable | ✅ Yes | ❌ No |

| Accuracy | ±1.5% to ±2.5% | ±1.0% to ±1.5% |

| Best For | Large pipes, retrofits | Precision, smaller pipes |

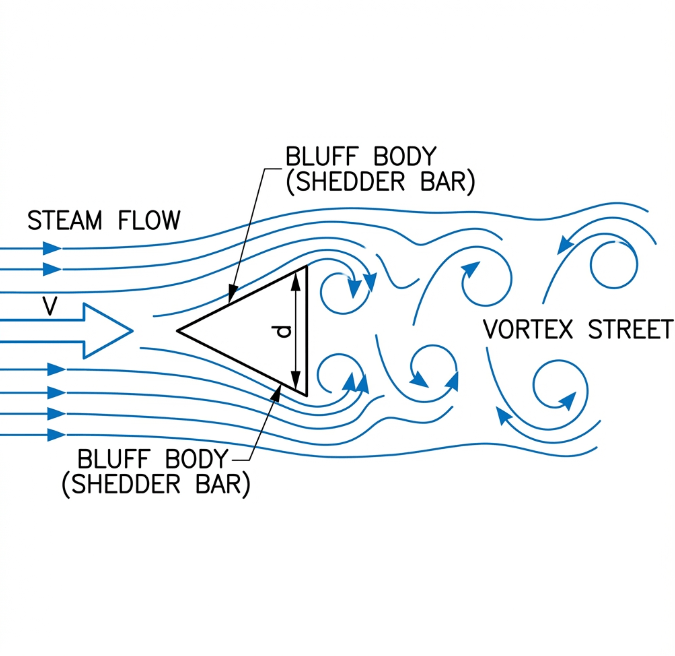

How It Works

The operating principle is identical to inline vortex meters. A bluff body (shedder bar) at the probe tip creates alternating vortices as fluid flows past. A piezoelectric sensor detects the pressure oscillations, and the electronics convert the frequency to velocity and then to volumetric or mass flow rate.

The key difference is that the probe measures velocity at a specific insertion depth — typically at the point of average velocity in the flow profile (about 12% of the pipe diameter from the wall for fully developed turbulent flow).

Technical Deep Dive: For the physics of vortex shedding, see Vortex Flow Measurement: How It Works & When It Fails.

Why Choose Insertion Over Inline?

1. Dramatic Cost Savings for Large Pipes

As pipe diameter increases, inline vortex meters become exponentially more expensive. The meter body, flanges, and installation costs all scale with size.

| Pipe Size | Inline Meter Cost (Typical) | Insertion Meter Cost (Typical) | Savings |

|---|---|---|---|

| DN100 | $2,500 | $2,800 | ❌ Inline cheaper |

| DN200 | $4,500 | $3,200 | 29% savings |

| DN300 | $8,000 | $3,500 | 56% savings |

| DN400 | $12,000 | $4,000 | 67% savings |

| DN600 | $18,000+ | $4,500 | 75% savings |

Break-even point: For most applications, insertion meters become more cost-effective at DN200 (8") and above.

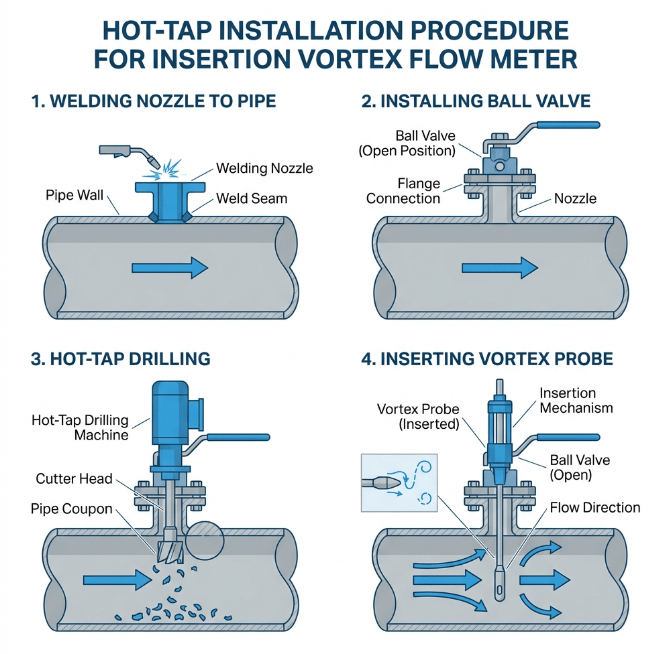

2. Hot-Tap Installation: No Shutdown Required

One of the biggest advantages is hot-tap installation — inserting the meter into a pressurized, operating pipeline without shutting down the process.

How Hot-Tap Works:

- Weld a nozzle and mounting flange to the pipe (while running)

- Install ball valve and retraction hardware

- Drill/cut through the pipe wall with hot-tap machine

- Insert the vortex probe through the ball valve

- Process continues uninterrupted throughout

In our field experience, hot-tap installation saves clients $20,000-$100,000 in avoided shutdown costs for critical steam or gas lines.

3. Simple Retrofit for Existing Systems

Adding flow measurement to an existing plant often requires working around operating constraints. Insertion meters are ideal for retrofits:

- No need to cut and re-weld large diameter pipes

- Minimal footprint — just a single pipe penetration

- Can be installed during brief maintenance windows

4. Easy Removal for Maintenance

With retractable insertion designs and ball valve isolation, you can remove the sensor for inspection or calibration without draining the pipe or stopping the process.

Technical Specifications: Soaring Instrument Insertion Vortex Flow Meter

Based on the Kármán vortex shedding principle, our insertion vortex meters are designed for large pipe industrial applications.

| Parameter | Specification |

|---|---|

| Measuring Medium | Liquid, gas, steam (saturated and superheated) |

| Pipe Diameter Range | DN80 – DN2000 |

| Medium Temperature | -40°C to +250°C (350°C optional) |

| Medium Pressure | Up to 4.0 MPa (higher available) |

| Accuracy | ±1.5% of reading (liquid); ±2.5% of reading (gas/steam) |

| Repeatability | ±0.2% |

| Velocity Range (Liquid) | 0.4 – 7 m/s |

| Velocity Range (Gas) | 4.0 – 60 m/s |

| Velocity Range (Steam) | 5.0 – 70 m/s |

| Body Material | 1Cr18Ni9Ti Stainless Steel |

| Output Signal | 4-20mA (loop powered), Pulse, RS485, HART |

| Power Supply | 24VDC (2-wire loop powered) or 3.6V lithium battery |

| Display | Double-row LCD, 8-digit |

| Protection Class | IP65 |

| Explosion-proof | Exd II CT6 Gb |

Model Options

| Model | Features | Best For |

|---|---|---|

| Standard Insertion | Volumetric flow output | Hot water, compressed air, liquids |

| With T Compensation | Integrated RTD for temperature | Saturated steam, process gases |

| With T&P Compensation | Integrated RTD + pressure sensor | Superheated steam, high-accuracy gas |

Installation Best Practices

Proper installation is critical for accurate flow measurement with insertion vortex meters. Here’s what we’ve learned from hundreds of installations:

Insertion Depth

The probe tip must be positioned at the point of average velocity in the fully developed flow profile. For round pipes with turbulent flow:

- Standard insertion depth: 0.120D to 0.130D from the pipe wall (where D = internal diameter)

- Most meters come with pipe-size-specific depth markers

Common Mistake: Inserting too deep or too shallow will cause systematic error in the flow reading.

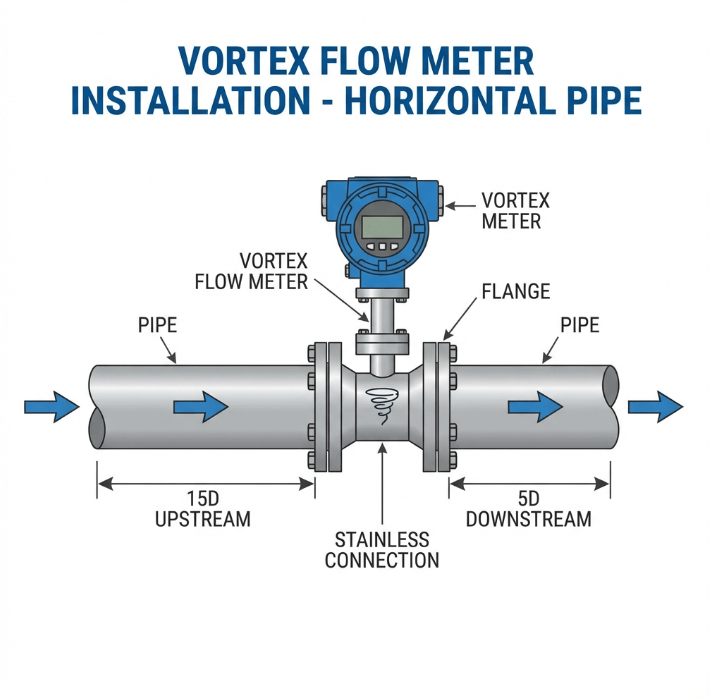

Straight Run Requirements

| Upstream Disturbance | Required Upstream | Required Downstream |

|---|---|---|

| Single elbow | 20D | 5D |

| Two elbows (same plane) | 25D | 5D |

| Two elbows (different planes) | 40D | 5D |

| Valve (fully open) | 20D | 5D |

| Flow conditioner | 10D | 5D |

Related: See Vortex Flow Meter Straight Run Requirement for detailed guidance.

Mounting Orientation

| Fluid Type | Recommended Probe Position |

|---|---|

| Liquid | From top or side (avoid bottom — sediment) |

| Gas | From top or side |

| Steam | From side (avoid top — condensate pockets) |

Hot-Tap Installation Procedure

- Site Survey: Confirm pipe material, wall thickness, and available straight run

- Nozzle Welding: Weld the mounting nozzle at the correct angle (perpendicular to flow)

- Pressure Test: Hydrotest the nozzle before hot-tap

- Hot-Tap Drilling: Use appropriate hot-tap machine for pipe size

- Probe Insertion: Insert probe to correct depth, verify alignment

- Commissioning: Configure meter parameters, verify signal

Real-World Applications

Case Study 1: Power Plant Steam Header

Challenge: A 300 MW power plant needed to measure superheated steam flow in their DN500 main header for energy accounting. Shutdown for inline meter installation was not possible.

Solution: We installed an insertion vortex flow meter with T&P compensation using hot-tap procedure.

Results:

- Installation time: 4 hours (zero downtime)

- Cost savings vs. inline: $14,000 (meter) + $50,000 (avoided shutdown)

- Accuracy achieved: ±2.0% mass flow rate

- Payback period: 3 months (through steam loss identification)

Case Study 2: Compressed Air Energy Audit

Challenge: An automotive parts manufacturer suspected high compressed air losses but had no metering on their DN300 distribution headers.

Solution: We installed 6 insertion vortex meters at strategic points without shutting down production.

Results:

- Leakage identified: 28% of compressor output

- Annual savings after repair: $65,000 in electricity

- Meter investment: $21,000 (6 units)

- Simple payback: 4 months

Frequently Asked Questions (FAQ)

What pipe sizes are suitable for insertion vortex flow meters?

Insertion vortex meters are most suitable for pipe sizes DN80 (3") and larger, with optimal cost-effectiveness starting at DN200 (8"). For very large pipes (DN1000+), insertion is often the only practical option.

How accurate is an insertion meter compared to inline?

With proper installation, insertion vortex meters achieve ±1.5% to ±2.5% accuracy — about 0.5-1.0% less than inline meters (±1.0% to ±1.5%). For most industrial applications, this difference is acceptable given the significant cost savings.

Can insertion vortex meters measure mass flow rate?

Yes. Models with integrated temperature and pressure sensors can calculate fluid density in real-time and output mass flow rate directly. This is essential for steam and gas measurement where density varies with process conditions.

What is hot-tap installation?

Hot-tap is a procedure for installing the meter on a pressurized, operating pipeline without shutting down the process. It involves welding a nozzle, drilling through the pipe wall with specialized equipment, and inserting the probe — all while the system remains in service.

How do I remove an insertion meter for calibration?

Retractable designs with ball valve isolation allow removal while the system is running. Close the ball valve, retract the probe through the packing gland or quick-connect, remove for calibration, and re-insert — all without draining the pipe.

Conclusion: Key Takeaways

Insertion vortex flow meters are cost-effective for pipes DN200 (8") and larger, saving 40-75% vs. inline meters.

Hot-tap installation eliminates process shutdowns — critical for continuous operations like power plants and refineries.

Accuracy of ±1.5% to ±2.5% is sufficient for most energy accounting, leak detection, and process monitoring applications.

Proper insertion depth (0.12D from wall) and straight run requirements must be followed for accurate flow measurement.

Retrofit applications benefit most — adding flow measurement to existing large pipes without major construction.

Get Expert Help: Insertion vs. Inline Selection

Not sure if insertion is right for your application? Our engineering team can evaluate your specific pipe size, fluid, process conditions, and accuracy requirements.

We provide:

- ✅ Free application review and meter sizing

- ✅ Insertion depth calculation for your pipe

- ✅ Hot-tap installation guidance

- ✅ T&P compensation recommendations

Request Free Technical Consultation | View Vortex Flow Meter Products

Related Articles

- Vortex Flow Measurement: How It Works & When It Fails

- Why Choose Vortex Flow Meters For Steam Applications?

- Vortex Flow Meter Straight Run Requirement

- What Is The Accuracy Of A Vortex Flow Meter And How Does It Compare?

- What Are the Main Applications of Vortex Flow Meters?

- How to Install an Insertion Type Flow Meter