Flow measurement in pipes under 2 inches has always been challenging. Traditional methods struggle with accuracy in tight spaces, but ultrasonic technology breaks through these barriers.

Ultrasonic flow meters measure small pipe flows using sound waves that pass through liquid at different speeds when moving with or against the flow, calculating velocity from the time difference. They overcome size limitations with high-frequency transducers (1-5MHz) achieving ±1% accuracy in pipes as small as 6mm diameter.

Ultrasonic Flow Meter

The applications for this technology range from chemical dosing to fuel monitoring. Let’s examine how it works in detail.

What Are the Methods of Ultrasonic Flow Measurement?

Three core techniques for different conditions:

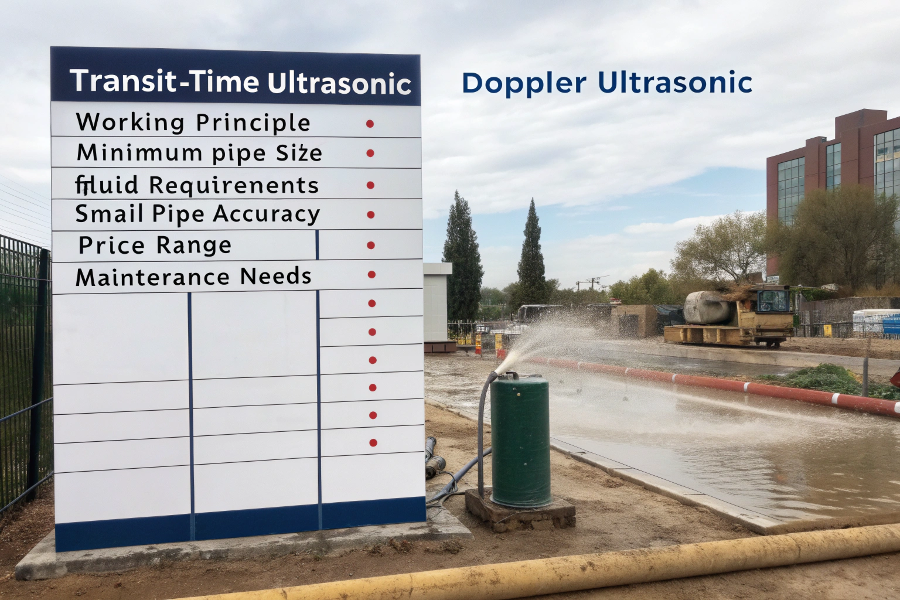

Main Ultrasonic Measurement Methods Comparison

| Method Name | Working Principle | Best For | Pipe Size Range | Accuracy |

|---|---|---|---|---|

| Transit-Time | Measures time difference of signals | Clean liquids | DN8-DN6000 | ±0.5-1% |

| Doppler | Detects frequency shift in echoes | Bubbly/slurry flows | DN50-DN1500 | ±2-5% |

| Cross-Correlation | Tracks particle patterns | Special research systems | DN15-DN300 | ±0.3% |

Three Ultrasonic Techniques

Emerging Hybrid Approaches

- Multi-path transit-time – Uses multiple beams for better profile measurement

- Combined Doppler/transit – Handles mixed condition flows

- Clamp-on portable – Temporary verification without pipe cutting

- Intrusive wetted – Higher accuracy for small pipes

Implementation Factors for Small Pipes

- Minimum straight run requirement (5D upstream, 3D downstream)

- Pipe material acoustic properties

- Fluid temperature and viscosity

- Available transducer mounting options

What Are the Disadvantages of an Ultrasonic Flow Meter?

Technical constraints in compact systems:

Small-Pipe Specific Limitations

- Signal attenuation – High frequency loss in tiny pipes

- Alignment sensitivity – 0.1° error causes 2% measurement deviation

- Bubble interference – Even micro-bubbles disrupt readings

- Inner surface quality – Roughness scatters ultrasound waves

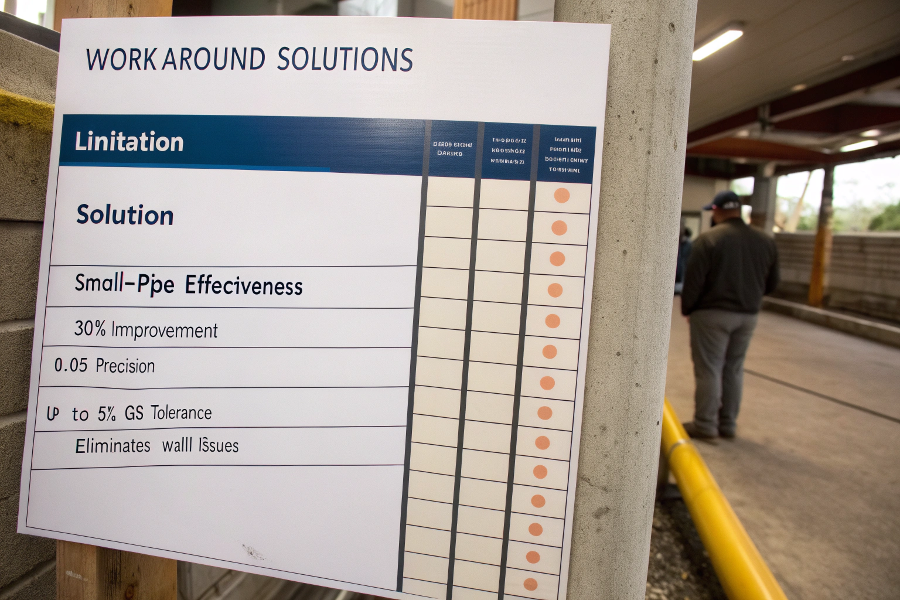

Workaround Solutions

| Limitation | Solution | Small-Pipe Effectiveness |

|---|---|---|

| Signal strength | Higher power transducers | 30% improvement |

| Alignment issues | Machined mounting brackets | ±0.05° precision |

| Bubble interference | Automatic bubble compensation | Up to 5% gas tolerance |

| Pipe wall effects | Inline wetted transducers | Eliminates wall issues |

Challenges in Tight Spaces

When Alternative Meters Perform Better

- Highly viscous fluids (>500cP)

- Non-conductive liquids (pure oils)

- Pipes with thick linings (>3mm)

- Systems with constant vibration

What Do Ultrasonic Meters Measure in a Closed Pipe System?

Complete measurement capabilities:

Primary Measurement Parameters

- Volumetric flow rate – Liquid volume passing per unit time

- Flow velocity – Speed of liquid movement

- Flow direction – Forward/reverse flow detection

- Speed of sound – Fluid property indicator

- Transit-time difference – Core measurement value

Derived Measurements

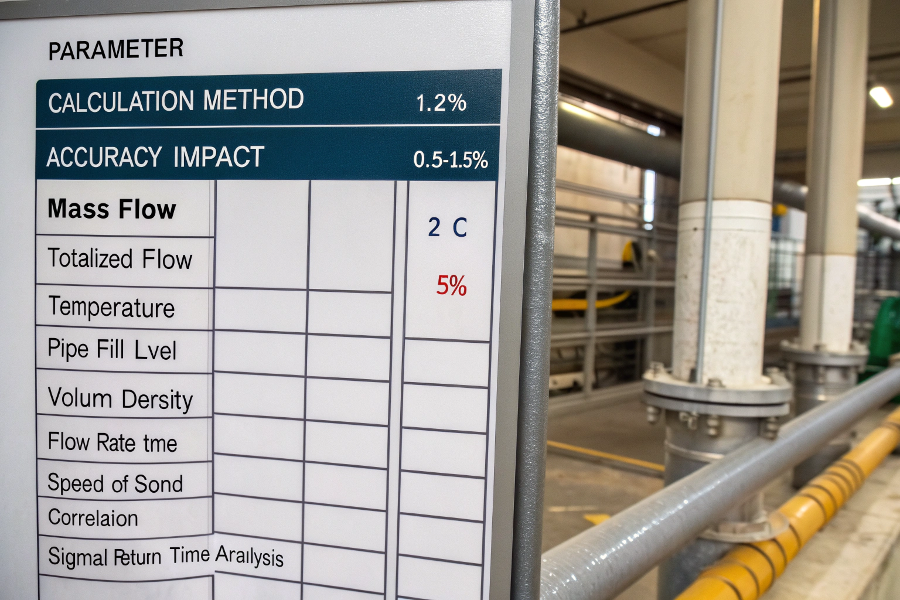

| Parameter | Calculation Method | Accuracy Impact |

|---|---|---|

| Mass flow | Volume × density | ±1-2% |

| Totalized flow | Flow rate × time | ±0.5-1.5% |

| Temperature | Speed of sound correlation | ±2°C |

| Pipe fill level | Signal return time analysis | ±5% |

Multi-Parameter Capabilities

Small-Pipe Measurement Enhancements

- Adaptive signal processing algorithms

- Dual-frequency transducer operation

- Automatic viscosity compensation

- Predictive error correction

- Self-diagnostic routines

How to Measure Flow With Ultrasound?

Step-by-step implementation guide:

Installation Process for Small Pipes

- Site preparation (straight runs, vibration isolation)

- Pipe surface treatment (cleaning, polishing)

- Transducer mounting (precise spacing/alignment)

- System configuration (pipe parameters, fluid data)

- Verification testing (baseline checks)

Essential Parameters to Set

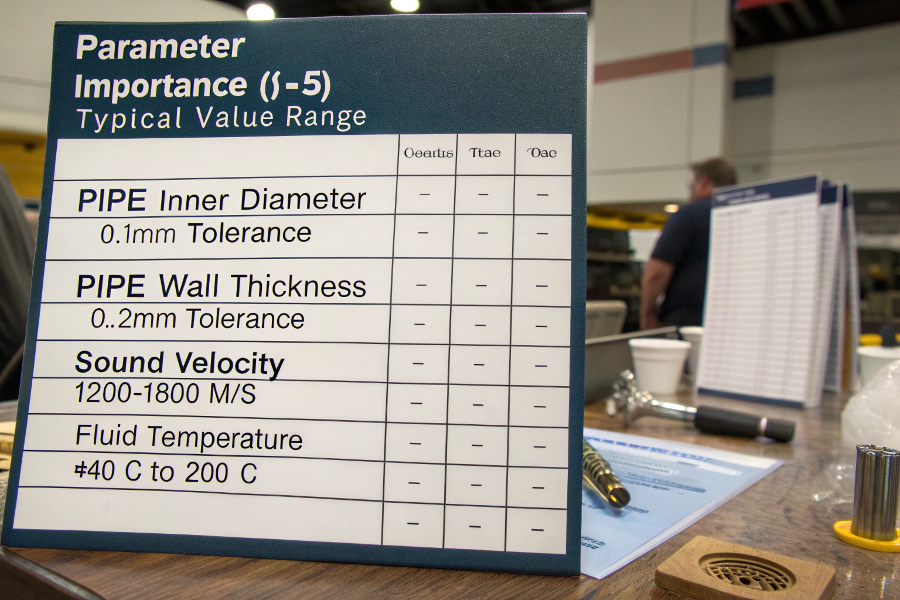

| Parameter | Importance (1-5) | Typical Value Range |

|---|---|---|

| Pipe inner diameter | 5 | ±0.1mm tolerance |

| Pipe wall thickness | 4 | ±0.2mm |

| Sound velocity | 5 | 1200-1800 m/s |

| Fluid temperature | 4 | -40°C to 200°C |

Step-by-Step Setup

Optimization Techniques

- Use factory wet calibration

- Implement automatic temperature compensation

- Schedule zero-flow verification

- Monitor signal quality indicators

- Apply advanced filtration algorithms

Conclusion

Modern ultrasonic technology enables precise flow measurement in pipes as small as 6mm through transit-time and Doppler methods, overcoming traditional small-pipe challenges with advanced signal processing and specialized transducers. While requiring careful installation and facing some fluid limitations, these non-intrusive systems deliver exceptional accuracy (±1%) where mechanical meters fail. Proper implementation following manufacturer guidelines ensures reliable performance in compact piping systems.