Many users struggle with ultrasonic flow meter setup, leading to inaccurate readings and wasted time and resources.

To use an ultrasonic flow meter, first clean the pipe surface, apply coupling gel, mount the transducers at the calculated spacing, connect cables, and input pipe parameters into the transmitter.

Basic Ultrasonic Flow Meter Setup

Let me share my practical experience to help you achieve accurate measurements.

How to Use an Ultrasonic Flow Meter?

Incorrect setup of ultrasonic flow meters often results in unreliable measurements and system failures.

Start by selecting the appropriate mounting location, measure pipe parameters, prepare the surface, mount transducers, and verify signal strength before taking measurements.

Step-by-Step Installation Guide

From my installation experience:

Installation Process

-

Pre-Installation Checks

Step Action Purpose Site Survey Check space Ensure accessibility Pipe Inspection Examine condition Verify suitability Parameter Collection Gather data Setup accuracy Tool Preparation Organize equipment Efficient installation -

Setup Procedure

- Clean pipe surface

- Mark mounting points

- Apply coupling gel

- Secure transducers

Configuration Steps

-

Parameter Entry

- Pipe dimensions

- Material properties

- Fluid characteristics

- Flow conditions

-

System Verification

- Signal strength check

- Zero flow validation

- Flow reading stability

- System diagnostics

How Do Ultrasonic Flowmeters Work?

Understanding the working principle is crucial for proper operation and troubleshooting.

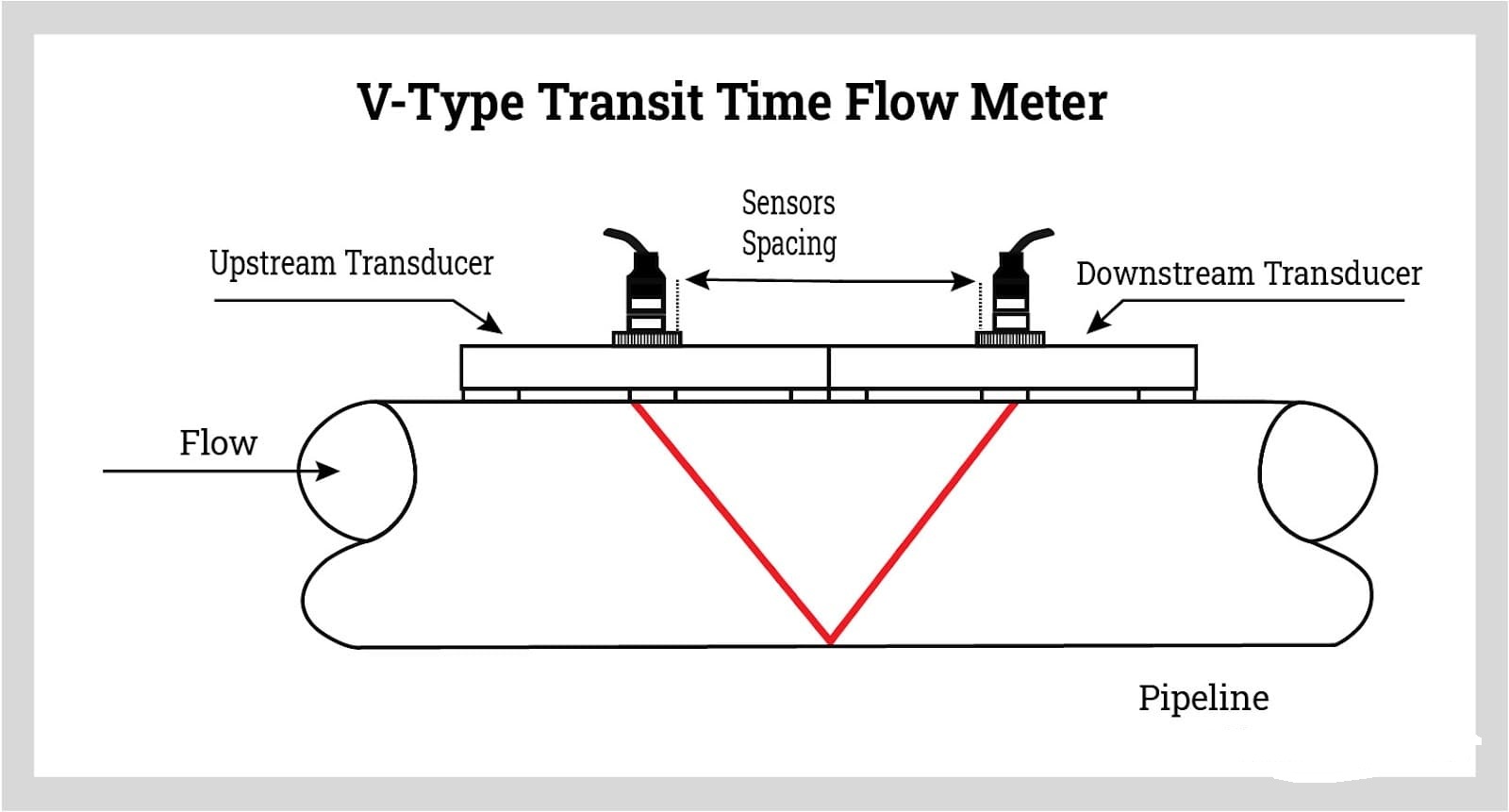

Ultrasonic flowmeters calculate flow rate by measuring the time difference between upstream and downstream ultrasonic signals traveling through the fluid.

Ultrasonic Flow Meter Operating Principle

Based on my technical knowledge:

Operating Principles

-

Measurement Methods

Type Principle Application Transit Time Time difference Clean liquids Doppler Frequency shift Dirty fluids Hybrid Combined Mixed applications Multi-path Multiple beams High accuracy -

Signal Processing

- Time measurement

- Flow calculation

- Error compensation

- Data output

Performance Factors

-

Accuracy Considerations

- Flow profile

- Installation conditions

- Fluid properties

- Signal quality

-

Environmental Effects

- Temperature changes

- Pressure variations

- Vibration impact

- External interference

How to Measure Flow with Ultrasound?

Poor measurement technique leads to significant errors in flow readings.

Measure flow with ultrasound by ensuring proper transducer spacing, good acoustic coupling, and correct parameter settings in the flow computer.

Ultrasonic Flow Measurement Technique

Drawing from my field experience:

Measurement Setup

-

Critical Parameters

Parameter Tool Importance Pipe Size Caliper Essential Wall Thickness Gauge Critical Flow Profile Straight run Important Signal Path Mounting method Crucial -

Measurement Process

- Parameter verification

- Signal optimization

- Data collection

- Result validation

Quality Assurance

-

Verification Steps

- Zero point check

- Span verification

- Repeatability test

- Stability monitoring

-

Maintenance Requirements

- Regular cleaning

- Signal checking

- Coupling inspection

- Calibration verification

How Does a Ultrasonic Doppler Flow Meter Work?

Misunderstanding Doppler principles can result in inappropriate application and measurement errors.

Doppler flow meters work by measuring the frequency shift of ultrasonic signals reflected from particles or bubbles in the flowing fluid.

Doppler Flow Meter Operation

From my expertise with Doppler systems:

Doppler Operation

-

Key Components

Component Function Requirement Transducer Signal emission Good contact Reflectors Echo generation Sufficient particles Processor Signal analysis Accurate processing Display Data presentation Clear readout -

Operating Conditions

- Particle content

- Flow velocity

- Fluid properties

- Installation requirements

Application Guidelines

-

Selection Criteria

- Fluid characteristics

- Process conditions

- Accuracy needs

- Installation constraints

-

Performance Optimization

- Mounting location

- Signal strength

- Processing settings

- Maintenance schedule

Conclusion

Success with ultrasonic flow meters requires proper installation, understanding of operating principles, and regular maintenance to ensure accurate and reliable measurements.