Many users find installing and operating ultrasonic flow meters challenging, leading to inaccurate measurements and wasted resources.

To use an ultrasonic flow meter effectively, you need to select proper installation locations, prepare the pipe surface, mount transducers correctly, and configure the meter settings accurately.

Ultrasonic Flow Meter Installation Steps

Ultrasonic Flow Meter Installation Steps

Let me share my practical experience to help you achieve optimal results with your ultrasonic flow meter installation.

How To Use An Ultrasonic Flowmeter?

Proper setup and operation are crucial for accurate flow measurements, but many users struggle with the initial configuration.

Using an ultrasonic flowmeter involves four key steps: site preparation, transducer mounting, parameter configuration, and system verification.

Ultrasonic Flow Meter Usage Guide

From my installation experience:

Installation Process

-

Site Preparation Steps

Step Action Purpose Verification Location selection Measure straight runs Ensure flow profile Use measuring tape Surface cleaning Remove paint/rust Improve contact Visual inspection Pipe measurement Get dimensions Accurate setup Caliper check Mark mounting points Calculate spacing Proper alignment Double-check math -

Critical Considerations

- Pipe material compatibility

- Flow conditions assessment

- Environmental factors

- Power supply availability

Operation Guidelines

-

Daily Operations

- Signal strength monitoring

- Zero point verification

- Data logging

- System alerts

-

Maintenance Requirements

- Regular cleaning

- Alignment checks

- Battery replacement

- Software updates

How Does An Ultrasonic Flowmeter Work?

Understanding the working principle helps users optimize their flow meter performance and troubleshoot issues effectively.

Ultrasonic flowmeters work by measuring the time difference between upstream and downstream sound wave signals to calculate fluid velocity and flow rate.

Ultrasonic Flow Meter Operating Principle

Based on my technical expertise:

Operating Principles

-

Measurement Methods

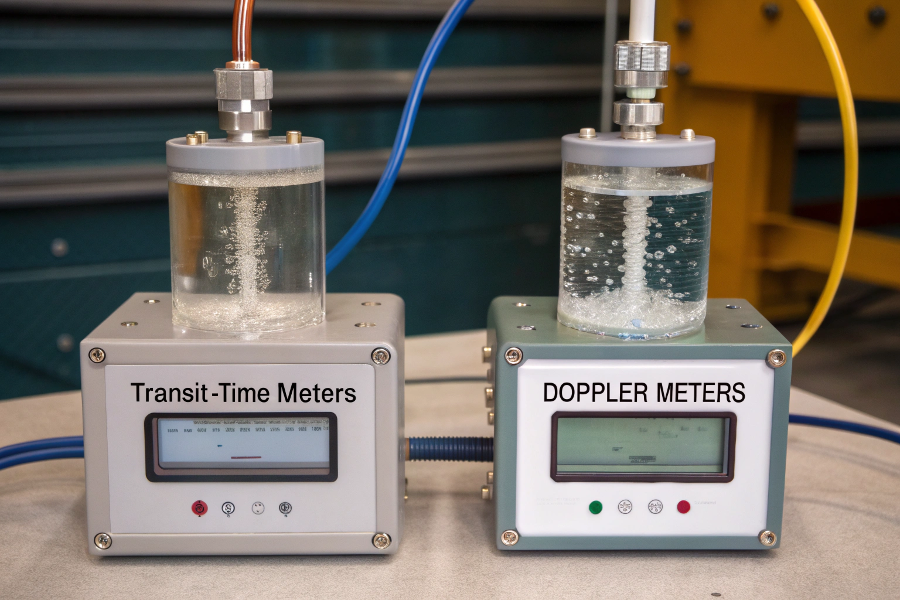

Method Description Advantage Application Transit-time Time difference measurement High accuracy Clean liquids Doppler Frequency shift detection Works with particles Dirty fluids Hybrid Combined technologies Versatility Mixed conditions Cross-correlation Pattern matching Advanced analysis Complex flows -

Signal Processing

- Wave generation

- Time measurement

- Flow calculation

- Data output

System Components

-

Hardware Elements

- Transducers

- Signal processors

- Display units

- Communication modules

-

Software Features

- Configuration tools

- Diagnostic utilities

- Data logging

- Analysis functions

How To Measure Flow With Ultrasound?

Accurate flow measurement requires proper technique and understanding of ultrasonic technology limitations.

To measure flow with ultrasound, install transducers at the correct spacing and angle, ensure good acoustic coupling, and input accurate pipe parameters into the meter.

Ultrasonic Flow Measurement Method

Drawing from my field experience:

Measurement Process

-

Setup Requirements

Parameter Importance Setting Method Verification Pipe size Critical Direct measurement Multiple points Wall thickness Essential Ultrasonic gauge Cross-check Fluid properties Important Documentation Lab analysis Flow profile Necessary Assessment Visual inspection -

Installation Factors

- Mounting method selection

- Acoustic coupling application

- Signal optimization

- Zero point calibration

Quality Assurance

-

Performance Validation

- Signal strength check

- Zero flow verification

- Range testing

- Repeatability assessment

-

Documentation Requirements

- Installation records

- Configuration data

- Performance logs

- Maintenance history

When To Use An Ultrasonic Flow Meter?

Selecting the right flow measurement technology for specific applications can be challenging.

Use ultrasonic flow meters when you need non-invasive measurement, require high accuracy, have clean liquids, or need flexibility in installation locations.

Ultrasonic Flow Meter Applications

Based on my implementation experience:

Application Selection

-

Best Use Cases

Application Benefit Requirements Considerations Clean liquids High accuracy Good pipe condition Straight runs Large pipes Cost effective Adequate access Signal strength Temporary measurement Portable Surface preparation Power supply Billing systems Non-intrusive Stable conditions Certification -

Industry Applications

- Water treatment

- HVAC systems

- Process control

- Energy management

Implementation Factors

-

Decision Criteria

- Process requirements

- Installation constraints

- Budget limitations

- Maintenance capability

-

Success Factors

- Proper planning

- Correct installation

- Regular maintenance

- Staff training

Conclusion

Successful ultrasonic flow meter use depends on proper installation, understanding of operating principles, and regular maintenance, ensuring accurate and reliable flow measurements for your application.