Signal loss in ultrasonic flow meters can lead to measurement inaccuracies and costly process control failures.

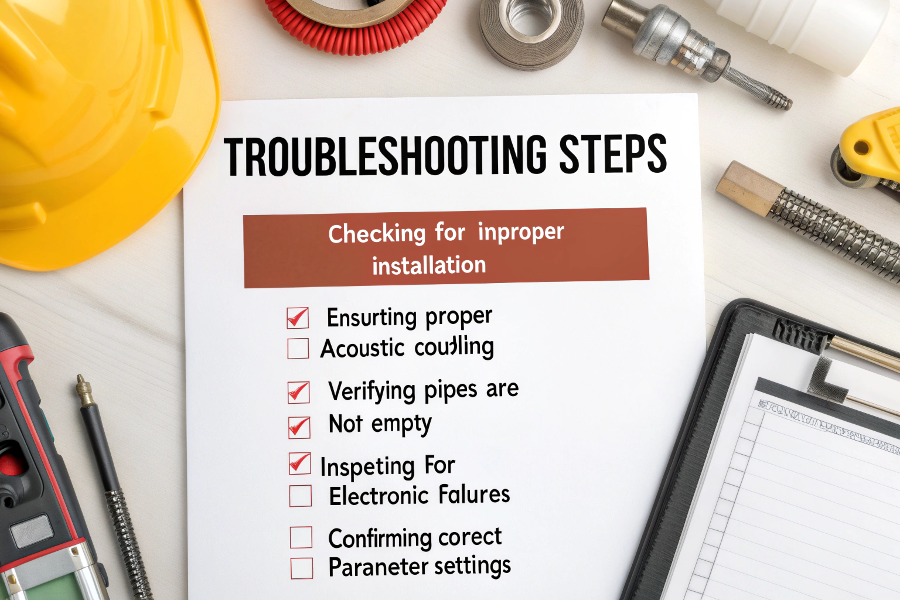

When an ultrasonic flow meter shows no signal, it’s typically due to poor transducer coupling, incorrect installation, empty pipes, or electronic failures.

Let me share my troubleshooting experience to help you resolve these common issues.

Why is My Ultrasonic Flow Meter Not Reading?

A non-reading flow meter can disrupt your entire process control system.

Common causes include improper installation, poor acoustic coupling, empty pipes, electronic failure, or incorrect parameter settings.

Flow Meter Troubleshooting Guide

Based on my field experience:

Common Issues

Installation Problems

Problem Symptom Solution Poor coupling Weak signal Reapply couplant Misalignment No reading Check mounting Empty pipe Zero flow Verify pipe fill Wrong settings Erratic reading Parameter check Environmental Factors

- Temperature effects

- Vibration issues

- Electrical interference

- Weather exposure

Verification Steps

Basic Checks

- Power supply

- Cable connections

- Display function

- Parameter settings

Advanced Diagnostics

- Signal strength

- Error messages

- Waveform analysis

- System logs

How to Tell if an Ultrasonic Flow Meter is Bad?

Identifying a faulty flow meter early can prevent process control disasters.

Signs of a bad flow meter include inconsistent readings, error messages, weak signal strength, and failure to respond to known flow changes.

Drawing from my maintenance experience:

Diagnostic Indicators

Performance Signs

Indicator Meaning Action Zero signal No transmission Check transducers Erratic readings Unstable measurement Verify installation Error codes System fault Diagnostic review Low strength Poor coupling Check mounting Testing Methods

- Signal verification

- Zero flow check

- Known flow test

- Response time

Validation Process

System Checks

- Hardware inspection

- Software verification

- Parameter review

- Performance test

Documentation

- Error history

- Maintenance records

- Calibration data

- Performance trends

What Causes Ultrasonic Flowmeter Malfunction?

Understanding root causes helps prevent recurring problems.

Ultrasonic Flow meter malfunctions commonly result from installation errors, environmental conditions, process changes, or component failure.

From my diagnostic experience:

Root Causes

Technical Issues

Cause Impact Prevention Installation Poor accuracy Proper setup Maintenance Degraded performance Regular checks Process changes Invalid readings Parameter updates Component wear System failure Timely replacement Environmental Factors

- Temperature extremes

- Moisture exposure

- Mechanical stress

- Electrical noise

Prevention Strategies

Maintenance Program

- Regular inspections

- Preventive maintenance

- Performance monitoring

- Staff training

System Protection

- Environmental controls

- Surge protection

- Physical guards

- Backup systems

How to Clean an Ultrasonic Flow Meter?

Improper cleaning can damage sensitive ultrasonic components.

Clean external ultrasonic flow meters using mild detergent, soft cloths, and proper couplant removal techniques while avoiding harsh chemicals.

Ultrasonic Flow Meters

Based on my maintenance procedures:

Cleaning Process

Step-by-Step Guide

Step Action Purpose Preparation Power off Safety Removal Careful dismount Access Cleaning Gentle wiping Maintenance Inspection Visual check Verification Material Requirements

- Cleaning supplies

- Replacement couplant

- Inspection tools

- Safety equipment

Best Practices

Safety Procedures

- Power isolation

- Chemical handling

- Tool selection

- Personal protection

Quality Checks

- Surface inspection

- Component testing

- Signal verification

- System restart

Conclusion

Regular maintenance, proper installation, and understanding common failure modes are key to preventing and resolving ultrasonic flow meter signal problems.