Installing clamp-on flow meters can be challenging, and incorrect installation leads to measurement errors and wasted resources.

A clamp-on flow meter installation requires proper pipe preparation, correct transducer positioning, and careful attention to mounting conditions to ensure accurate flow measurement.

Clamp-on Flow Meter Installation Overview

Let me share my installation expertise to help you achieve optimal flow meter performance.

How Do Clamps On Ultrasonic Flow Meters Work?

Many users find ultrasonic flow measurement technology complex and mysterious.

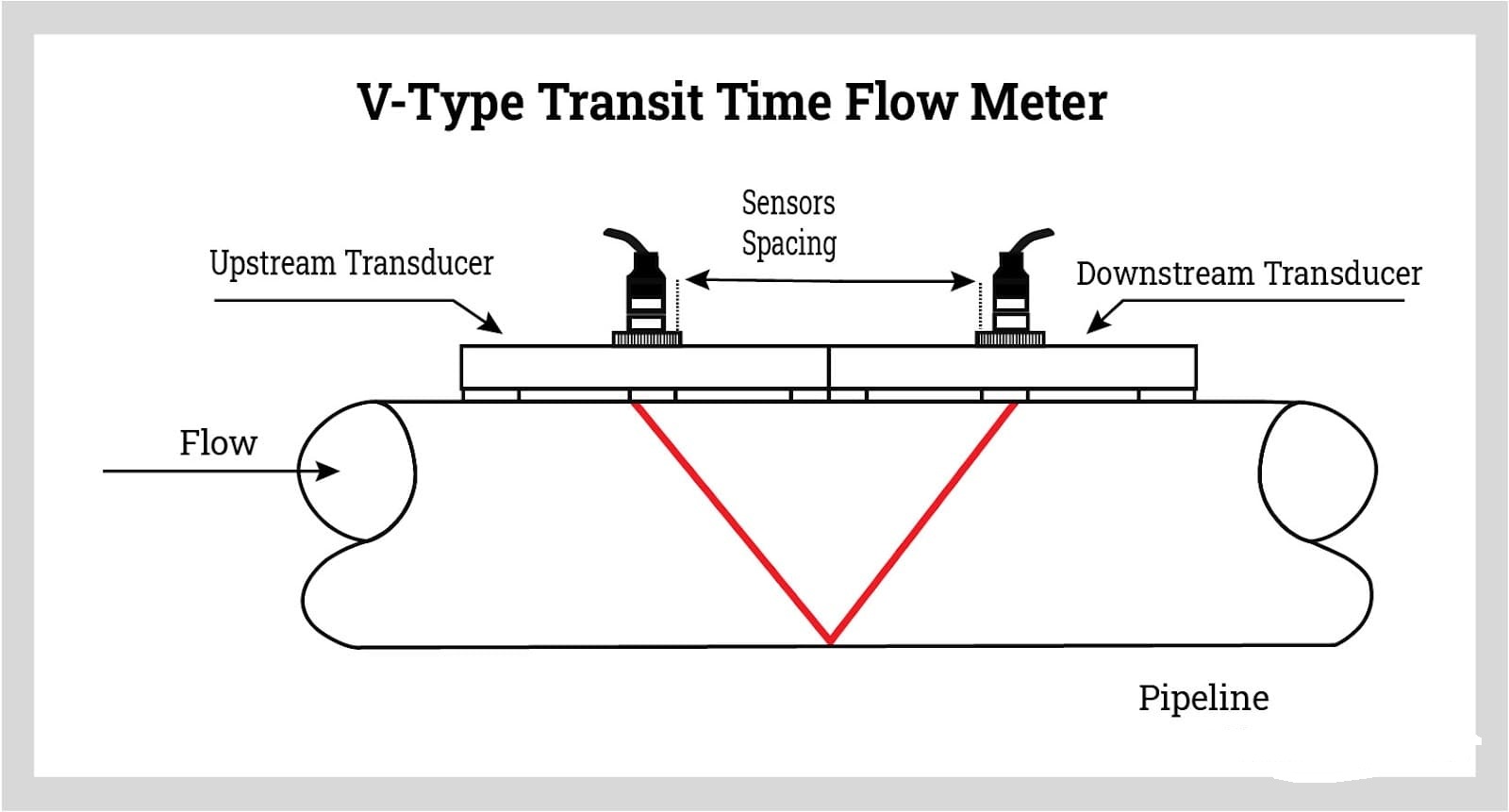

Clamp-on ultrasonic flow meters work by sending sound waves through pipe walls diagonally across the fluid, measuring flow rate based on the time difference between upstream and downstream signals.

Ultrasonic Flow Meter Working Principle

From my technical experience:

Operating Principles

-

Signal Transmission

Component Function Purpose Impact Transducer Generate waves Flow detection Accuracy Pipe wall Wave conductor Signal path Transmission Fluid Medium Flow measurement Results Electronics Processing Data analysis Output -

Measurement Process

- Sound wave generation

- Signal transmission

- Time difference calculation

- Flow rate computation

Key Components

-

System Elements

- Transducer pairs

- Mounting hardware

- Control unit

- Display interface

-

Signal Path

- Wave transmission

- Fluid interaction

- Signal reception

- Data processing

How To Install An Ultrasonic Flowmeter?

Poor installation practices often result in unreliable measurements and operational issues.

Installation involves selecting the right location, preparing the pipe surface, mounting transducers at the correct spacing, and verifying signal quality.

Flow Meter Installation Steps

Based on my installation experience:

Installation Steps

-

Site Preparation

Step Action Purpose Verification Location selection Check straight run Flow profile Distance measurement Surface cleaning Remove rust/paint Signal quality Visual inspection Marking points Identify positions Alignment Measurement check Apply coupling Use acoustic gel Signal transfer Coverage check -

Mounting Process

- Calculate spacing

- Mount brackets

- Install transducers

- Connect cables

Verification Process

-

Quality Checks

- Signal strength

- Zero flow check

- Flow reading

- Error messages

-

Documentation

- Installation parameters

- Signal quality data

- Flow readings

- System settings

What Material Is Used For Ultrasonic Flow Meter Pipe?

Choosing the wrong pipe material can lead to poor measurement performance and system failure.

Ultrasonic flow meters work best with metal pipes (steel, copper) and certain plastics (PVC, HDPE) that provide good sound transmission properties.

Suitable Pipe Materials

Drawing from my material expertise:

Material Selection

-

Metal Pipes

Material Properties Advantages Limitations Stainless Steel Excellent sound Durability Cost Carbon Steel Good transmission Common Corrosion Copper High conductivity Easy install Price variation Aluminum Light weight Cost effective Softness -

Plastic Pipes

- PVC specifications

- HDPE characteristics

- Material limitations

- Temperature ranges

Application Considerations

-

Selection Factors

- Operating temperature

- Pressure requirements

- Chemical compatibility

- Cost constraints

-

Installation Impact

- Sound transmission

- Signal strength

- Mounting options

- Maintenance needs

What Are The Disadvantages Of Clamp-on Ultrasonic Flow Meter?

Understanding limitations helps prevent application mistakes and ensures successful implementation.

Main disadvantages include sensitivity to air bubbles, pipe condition requirements, installation expertise needs, and limitations with certain fluid types.

Flow Meter Disadvantages

From my troubleshooting experience:

Common Issues

-

Technical Limitations

Issue Impact Solution Prevention Air bubbles Signal loss Vertical mounting Proper venting Pipe condition Poor signals Surface prep Maintenance Installation skill Errors Training Expert support Environmental factors Interference Protection Site selection -

Application Constraints

- Flow profile requirements

- Temperature sensitivity

- Straight run needs

- Fluid restrictions

Performance Impact

-

Measurement Effects

- Accuracy variation

- Signal quality

- Response time

- Reliability issues

-

Operational Concerns

- Maintenance requirements

- Calibration needs

- Environmental sensitivity

- Cost implications

Conclusion

Successful clamp-on flow meter installation requires proper preparation, understanding of working principles, suitable pipe material selection, and awareness of limitations to ensure accurate flow measurement.