Incorrect level switch selection for tanks can result in overflow accidents, pump damage, and costly production losses.

Tank level switches are devices that monitor and control liquid levels, providing automatic alerts or control actions when liquid reaches specific points in the tank.

%(percentage)tank-level-switch

Tank Level Switch Installation

I’ve helped numerous customers solve their tank monitoring challenges. Let me share what I’ve learned.

What is the Level Switch for a Water Tank?

Many facility managers struggle with selecting the right level switch for their water tanks.

A water tank level switch is a device that monitors water levels and triggers actions like pump control or alarms when water reaches predetermined high or low points.

Water Tank Level Switch Setup

From my installation experience:

Types of Water Tank Switches

Common Applications

Switch Type Best Use Features Float General purpose Simple, reliable Conductivity Clean water No moving parts Ultrasonic Large tanks Non-contact Capacitive Various liquids Versatile Selection Factors

- Tank size and shape

- Water quality

- Environmental conditions

- Maintenance requirements

Installation Requirements

Mounting Considerations

- Access points

- Cable routing

- Weather protection

- Maintenance space

Safety Features

- Overflow prevention

- Dry-run protection

- Backup systems

- Alarm integration

These factors ensure proper operation.

How Does a Water Tank Level Sensor Work?

Understanding sensor operation is crucial for proper application and maintenance.

Water tank level sensors use various technologies like floatation, pressure, or electronic sensing to detect water presence and convert it into electrical signals for monitoring.

Tank Level Sensor Operation

Based on my technical expertise:

Operating Principles

Sensing Technologies

Method Operation Advantages Float Physical displacement Simple, direct Pressure Hydrostatic force Continuous reading Ultrasonic Echo timing Non-contact Optical Light reflection Clean operation Signal Processing

- Level detection

- Output conversion

- Calibration methods

- Error compensation

Performance Factors

Accuracy Considerations

- Resolution needs

- Response time

- Temperature effects

- Turbulence impact

Maintenance Aspects

- Cleaning requirements

- Calibration checks

- Part replacement

- Troubleshooting

These principles guide proper selection.

What is the Function of a Level Switch?

Many users don’t fully understand the critical roles level switches play in tank systems.

Level switches serve multiple functions including overflow prevention, pump protection, process control, and inventory management by monitoring specific points in tanks.

Level Switch Functions

Drawing from my application experience:

Primary Functions

Control Applications

Function Purpose Benefit High Level Overflow prevention Safety Low Level Pump protection Equipment life Process Automation control Efficiency Interface Layer detection Quality System Integration

- Alarm systems

- Control circuits

- Data logging

- Remote monitoring

Implementation Strategies

Safety Considerations

- Redundancy

- Fail-safe operation

- Emergency response

- Regular testing

Control Methods

- Direct switching

- PLC integration

- Manual override

- Feedback systems

These functions ensure system reliability.

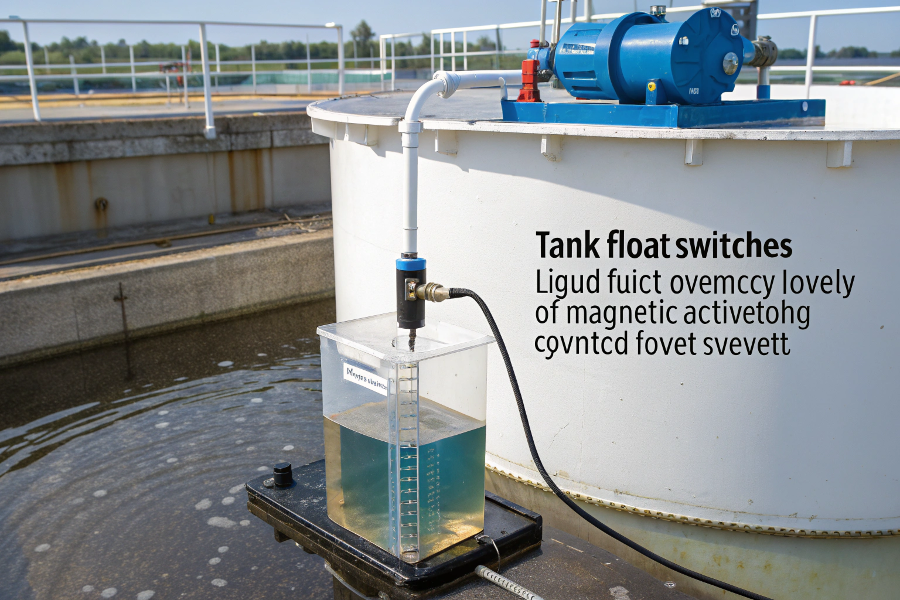

How Does a Tank Float Switch Work?

Float switches are common but often misunderstood in their operation and limitations.

Tank float switches use buoyancy to detect liquid levels, with a floating element activating a mechanical or magnetic switch when the liquid level changes.

Float Switch Operation

From my field experience:

Operating Mechanism

Component Functions

Part Purpose Operation Float Level detection Buoyancy Pivot Movement Mechanical Switch Signal generation Electrical Housing Protection Environmental Design Variations

- Vertical mount

- Side mount

- Multi-point

- Tethered

Application Guidelines

Installation Requirements

Factor Consideration Impact Mounting Location access Operation Wiring Protection Reliability Testing Regular checks Maintenance Documentation Records Compliance Maintenance Needs

- Regular inspection

- Cleaning schedule

- Parts replacement

- Performance verification

These guidelines ensure proper operation.

Conclusion

Successful tank level switch implementation requires understanding of the application, proper selection of technology, and regular maintenance to ensure reliable operation and safety.