Steam flow measurement challenges can lead to energy waste, safety risks, and inefficient process control.

Vortex flow meters are ideal for steam measurement, offering high accuracy, temperature resistance up to 400°C, and reliable performance without moving parts.

Vortex Flow Meter in Steam Applications

Let me share my expertise in steam flow measurement using vortex technology.

Which Flowmeter is Best for Steam Measurement?

Steam flow measurement errors can significantly impact energy costs and process efficiency.

For steam applications, vortex flow meters are the preferred choice, followed by differential pressure devices and specialized thermal mass meters.

Steam Flow Meter Comparison

From my steam measurement experience:

Technology Comparison

Meter Types

Type Accuracy Pressure Loss Installation Cost Vortex ±0.5% Medium Medium DP Orifice ±1.5% High Low Target ±2% Low Low Thermal ±1% None High Selection Factors

- Steam conditions

- Pressure ranges

- Temperature limits

- Space requirements

Performance Considerations

Operating Parameters

- Flow ranges

- Pressure ratings

- Temperature limits

- Material compatibility

Installation Requirements

- Straight run needs

- Support structures

- Insulation requirements

- Maintenance access

What Type of Steam Flow Meter is Vortex?

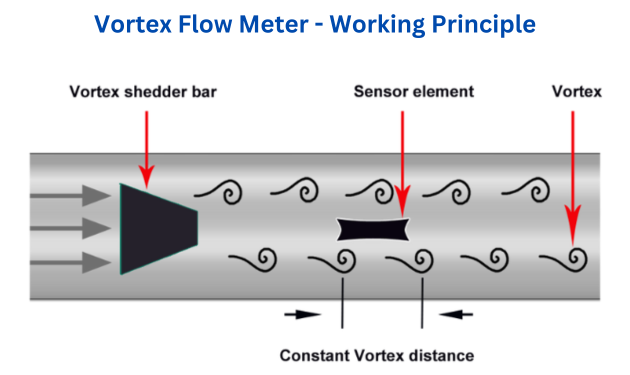

Understanding vortex meter principles helps optimize steam measurement.

A vortex steam flow meter uses a bluff body to create alternating vortices, measuring their frequency to determine flow rate, while compensating for temperature and pressure.

Vortex Steam Flow Meter Operating Principle

Based on my technical knowledge:

Technical Details

Operating Components

Component Function Critical Features Bluff Body Vortex generation Heat resistant Sensor Vortex detection High temp rated Electronics Signal processing Isolated design Housing Protection Insulated Measurement Process

- Steam conditioning

- Vortex formation

- Signal detection

- Flow calculation

Design Features

Construction Elements

- Material selection

- Sensor protection

- Thermal isolation

- Condensation management

Performance Features

- Temperature compensation

- Pressure correction

- Density calculation

- Mass flow output

What are the Applications of Vortex Flow Meters?

Proper application knowledge prevents costly measurement errors.

Vortex meters excel in steam, gas, and clean liquid applications, particularly in utilities, power generation, and process industries.

Vortex Flow Meter Applications

Drawing from my field experience:

Application Areas

Steam Systems

Application Benefits Challenges Boiler Feed High accuracy Installation space Steam Distribution Low maintenance Insulation needs Energy Monitoring Direct mass flow Condensation Process Steam Temperature resistant Pressure loss Installation Considerations

- Pipe orientation

- Flow conditioning

- Thermal management

- Vibration control

Best Practices

System Design

- Size optimization

- Material selection

- Installation planning

- Performance verification

Operational Aspects

- Startup procedures

- Regular inspection

- Maintenance schedules

- Calibration needs

How to Measure the Flow of Steam?

Steam flow measurement requires careful attention to physical properties and conditions.

Steam flow measurement involves selecting appropriate technology, considering pressure and temperature effects, and proper installation for accurate results.

Steam Flow Measurement Methods

Based on my measurement expertise:

Measurement Methods

Key Considerations

Parameter Impact Solution Pressure Density variation Compensation Temperature Steam quality Superheated use Installation Accuracy Proper sizing Maintenance Reliability Regular checks Implementation Steps

- System analysis

- Meter selection

- Installation planning

- Commissioning

Optimization Tips

Design Phase

- Steam conditions

- Flow ranges

- Pressure drops

- Temperature limits

Operational Phase

- Monitoring methods

- Maintenance procedures

- Performance checks

- Troubleshooting guides

Conclusion

Vortex flow meters provide reliable steam measurement when properly selected, installed, and maintained, offering excellent accuracy and long-term stability for steam applications.