Calculating K-factor wrongly can lead to significant measurement errors and costly process control issues.

The K-factor in vortex flow meters represents the number of pulses generated per unit volume of fluid flow, typically expressed as pulses/m³ or pulses/gallon.

K-Factor Calculation Diagram

Let me share my experience with K-factor calculations and calibrations from numerous field installations.

What Is The K-Factor In Calibration?

Calibration accuracy directly impacts flow measurement reliability and process control.

The calibration K-factor represents the meter’s response characteristic, serving as a conversion factor between pulse output and actual flow volume.

Flow Meter Calibration Setup

Flow Meter Calibration Setup

Based on my calibration experience:

Calibration Process

Setup Requirements

Component Purpose Specification Reference Standard Accuracy basis ±0.1% or better Test Equipment Flow generation Stable flow source Data System Recording High resolution Temperature Control Stability ±1°C variation Testing Protocol

- Multiple flow points

- Repeatability checks

- Linearity verification

- Uncertainty calculation

Quality Assurance

Documentation

- Raw data records

- Calculation sheets

- Uncertainty analysis

- Traceability information

Verification Steps

- Standard comparison

- Historical review

- Performance trending

- Acceptance criteria

How To Calculate K-Factor For Vortex Flow Meter?

Many engineers struggle with determining accurate K-factors for their specific applications.

K-factor is calculated by dividing the number of pulses counted during calibration by the actual volume of fluid that passed through the meter during that period.

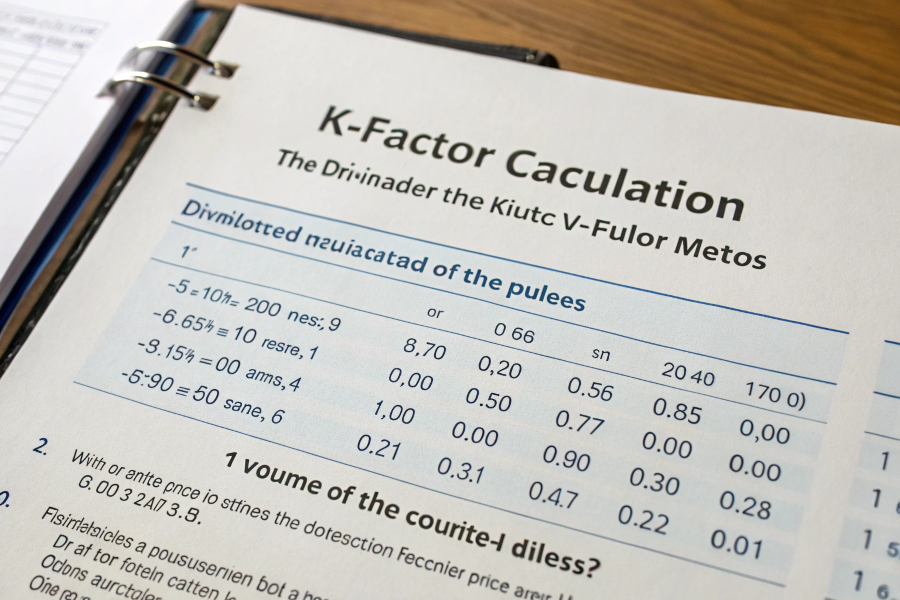

K-Factor Calculation Method

From my calibration experience:

Calculation Process

Basic Formula Components

Parameter Unit Description Pulse Count Pulses Total pulses during test Volume m³ or gallons Measured fluid volume Time seconds Test duration Flow Rate m³/h or GPM Average flow rate Calculation Steps

- Collect pulse data

- Measure actual volume

- Calculate ratio

- Apply correction factors

- Verify results

Influencing Factors

Process Variables

- Fluid properties

- Temperature effects

- Pressure conditions

- Reynolds number

Equipment Considerations

- Meter size

- Installation effects

- Signal processing

- Electronic resolution

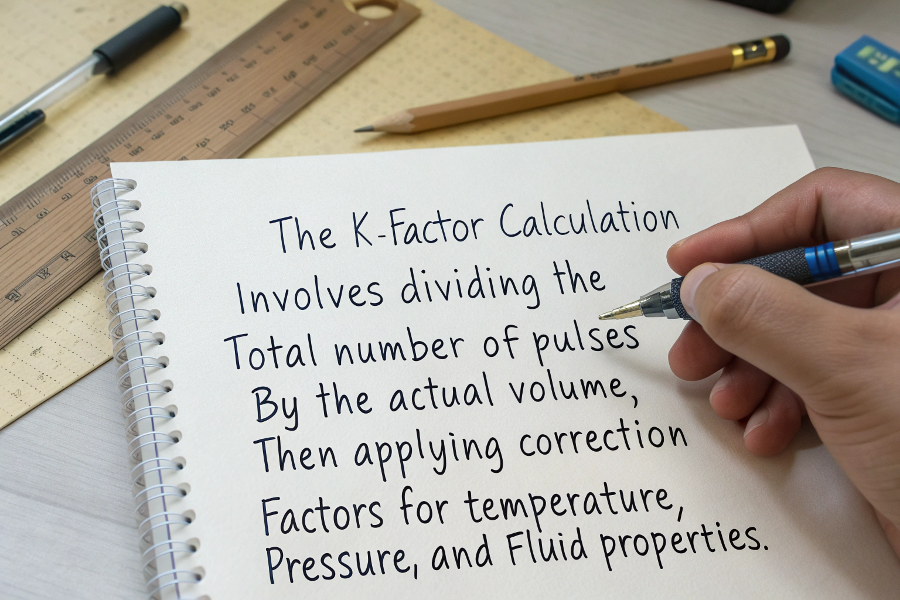

How Is The K-Factor Calculated?

Understanding the mathematics behind K-factor calculation ensures accurate flow measurement.

The K-factor calculation involves dividing the total number of pulses by the actual volume, then applying correction factors for temperature, pressure, and fluid properties.

K-Factor Calculation Factors

Drawing from my technical expertise:

Mathematical Approach

Basic Equation

Step Formula Variables Raw K-factor K = P/V P=pulses, V=volume Temperature correction Kt = K × (1 + αΔT) α=temp coefficient Pressure correction Kp = Kt × (1 + βΔP) β=pressure coefficient Final K-factor Kf = Kp × Cf Cf=correction factor Correction Factors

- Material expansion

- Fluid density changes

- Reynolds number effects

- Installation effects

Practical Implementation

- Calibration Requirements

- Standard conditions

- Reference equipment

- Data collection

- Uncertainty analysis

What Is The K-Factor In An Energy Meter?

Energy meters require special consideration for K-factor calculations to ensure accurate energy consumption measurement.

In energy meters, the K-factor combines flow measurement with temperature differential and specific heat capacity to calculate energy transfer rates.

From my energy measurement experience:

Energy Calculation Components

Measurement Parameters

Parameter Unit Purpose Flow Rate m³/h Volume measurement Temperature Δ °C Energy transfer Specific Heat kJ/kg°C Energy content Density kg/m³ Mass calculation Integration Factors

- Time base conversion

- Units conversion

- Density compensation

- Temperature effects

System Implementation

Configuration Requirements

- Parameter setup

- Units selection

- Range settings

- Alarm limits

Operational Considerations

- Regular verification

- Calibration intervals

- Data logging

- Performance monitoring

Conclusion

Accurate K-factor calculation and calibration are essential for reliable flow measurement, requiring careful consideration of process conditions and proper calibration procedures.