Many users struggle with inaccurate flow measurements because of incorrect calculations and setups, leading to costly process control errors.

Ultrasonic flow meter calculations involve measuring transit time differences or Doppler shifts, with accuracy depending on proper pipe diameter, fluid properties, and installation parameters.

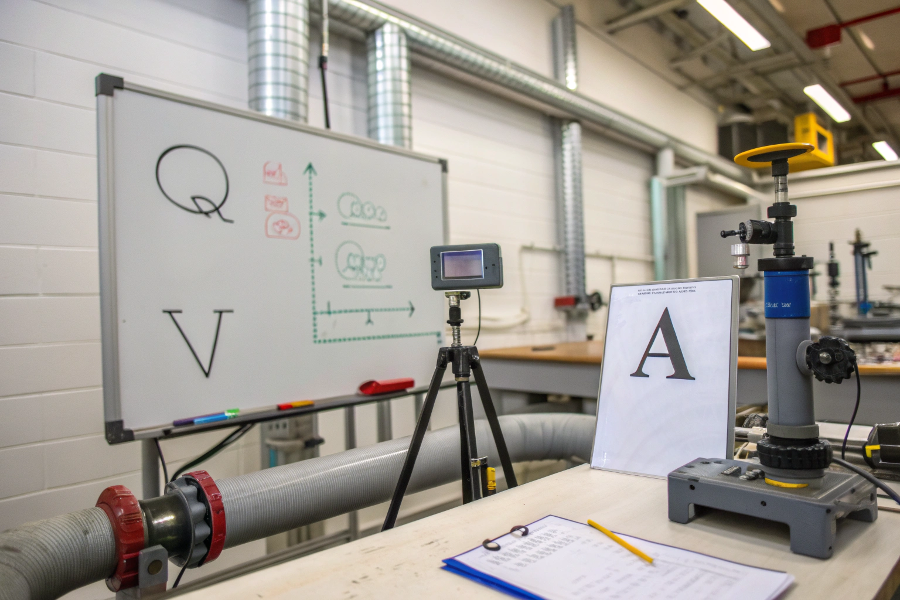

Flow Calculation Fundamentals

Let me share my experience in helping customers achieve accurate flow measurements through proper calculations and setup.

How to Measure Ultrasonic Flow Meter?

Wrong measurement setup can lead to significant errors in flow readings and process control issues.

Proper measurement requires correct transducer spacing, accurate pipe parameters, and consideration of fluid properties while ensuring proper straight pipe runs.

Ultrasonic Flow Meter Setup

Based on my installation experience:

Key Setup Parameters

Essential Measurements

Parameter Importance Measurement Method Pipe OD Critical Caliper/Tape Wall Thickness1 High Ultrasonic Gauge Fluid Temperature Important Temperature Probe Flow Profile Significant Visual Inspection Installation Considerations

- Mounting location selection

- Transducer orientation

- Signal strength verification

- Zero point calibration

Measurement Process

Pre-installation Steps

- Site survey

- Parameter collection

- Installation planning

- Tool preparation

Setup Procedure

- Surface preparation

- Transducer mounting

- Parameter entry

- System verification

How to Calculate the Ultrasonic Flow Meter?

Incorrect flow calculations can result in significant measurement errors and process control problems.

Flow calculation involves using the formula Q = V × A, where Q is flow rate, V is fluid velocity from transit time measurement, and A is pipe cross-sectional area.

Flow Calculation Methods

Drawing from my technical expertise:

Calculation Methods

Basic Flow Equations

Parameter Formula Units Flow Rate Q = V × A m³/h Velocity V = L/(2cosθ) × Δt m/s Area A = π(D²/4) m² Important Factors

- Reynolds number

- Flow profile correction

- Temperature compensation

- Pressure effects

Practical Implementation

Calculation Steps

- Parameter verification

- Data collection2

- Formula application

- Result validation

Correction Factors

- Installation effects

- Fluid properties

- Environmental conditions3

- System calibration

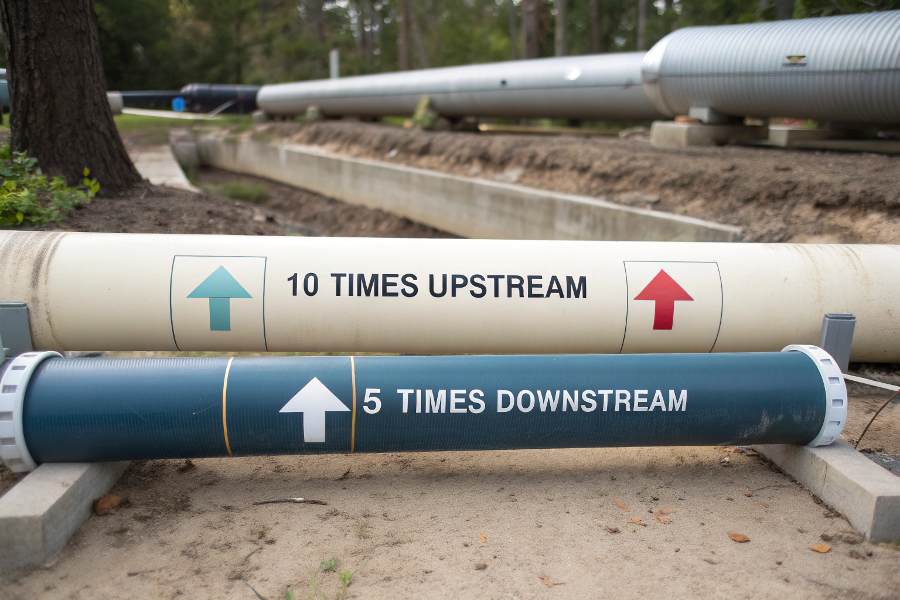

What is 10D and 5D in a Ultrasonic Flow Meter?

Ignoring proper straight run requirements is a common cause of measurement inaccuracies.

10D and 5D refer to required straight pipe lengths: 10 times pipe diameter upstream and 5 times downstream of the meter for accurate measurement.

Pipe Straight Run Requirements

From my field experience:

Straight Run Requirements

Installation Guidelines

Location Requirement Purpose Upstream 10D minimum Flow Profile Downstream 5D minimum Recovery Zone Bends 20D for double Profile Stabilization Pumps 30D minimum Swirl Reduction Impact Factors

- Flow disturbances

- Pipe fittings

- Valve locations

- Equipment proximity

Implementation Solutions

Space Constraints

- Flow conditioners

- Alternative locations

- Profile correction

- Accuracy adjustment

Verification Methods

- Flow profile analysis

- Signal quality check

- Performance validation

- Error assessment

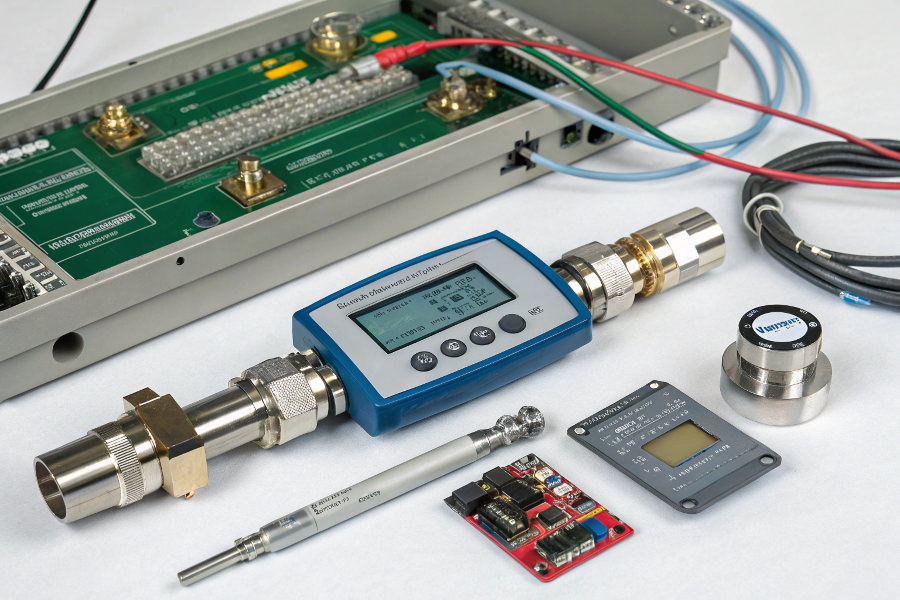

How to Make an Ultrasonic Flow Meter?

Building a DIY ultrasonic flow meter without proper knowledge can lead to unreliable measurements.

Creating an ultrasonic flow meter requires ultrasonic transducers, signal processing electronics, and precise timing circuits, along with proper calibration capabilities.

Flow Meter Components

Based on my manufacturing knowledge:

Components Required

Essential Elements

Component Function Specification Transducers Signal Generation 1-2 MHz typical Electronics Signal Processing High-speed ADC Microcontroller Calculations 32-bit minimum Display User Interface LCD/OLED Support Systems

- Power supply

- Signal amplification

- Temperature sensing

- Communication interface

Assembly Process

Design Considerations

- Circuit layout

- Component selection

- Housing design

- Software development

Testing Requirements

- Signal verification

- Calibration setup

- Performance testing

- Certification compliance

Conclusion

Successful ultrasonic flow measurement requires proper calculation, installation planning, and attention to straight run requirements, combined with regular validation and maintenance procedures.

Wall Thickness measurement is vital for assessing the strength and durability of pipes. ↩

Understanding data collection methods is crucial for accurate results in any practical implementation. ↩

Exploring the impact of environmental conditions can enhance your project’s effectiveness and reliability. ↩