The high initial cost of flow meters often makes buyers hesitate, potentially leading to choosing cheaper but less suitable alternatives.

Ultrasonic flow meters typically cost between $1,000 to $15,000, with portable units ranging from $2,000 to $6,000 and permanent installations costing $3,000 to $15,000.

Ultrasonic Flow Meter Overview

| Performance | |

|---|---|

| Flow Rate | ±0.03m/s~±12m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% of measured value |

| Linearity | ±1% |

| Pipe Size | DN25-DN1200 |

| Function | |

| Output | Analog output: 4-20mA, Max. load 750Ω ;Pulse output: 0~10KHz |

| Communication | RS232/RS485 Modbus(M-Bus or Hart is optional) |

| Power Supply | 10-36VDC / 90-245VAC |

| Display | 240*128 backlit LCD |

| Temperature | Transmitter:-20℃–60℃;Transducer:-40℃–80℃(TT01,TT02);Transducer:-40℃–130℃(TT03,TT05);Transducer:-40℃–180℃(TT02H);Transducer:0℃–65℃(TT02S);Transducer:0℃–135℃(TT03S) |

| Humidity | Up to 99%RH, non-condensing |

| Physical | |

| Transmitter | PC+ABS, IP65 |

| Transducer | Enccapulated design IP68;Double-shielded transducer cable;Standard/Max. cable length: 30ft/1000ft(9m/300m) |

Let me share insights from my experience in selling and implementing ultrasonic flow measurement solutions.

Are Ultrasonic Flow Meters Accurate?

Poor accuracy can result in process inefficiencies, billing disputes, and compliance issues.

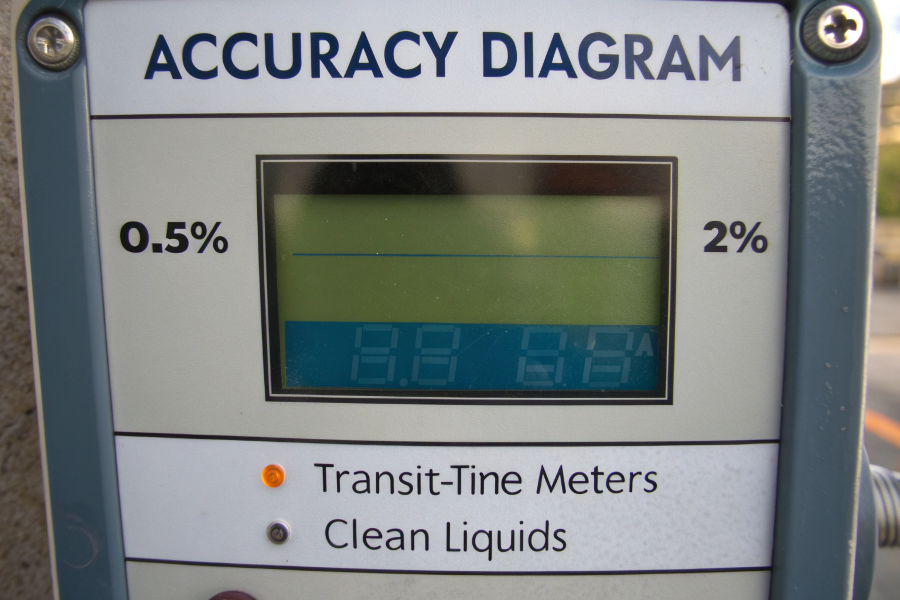

Ultrasonic flow meters achieve accuracies of ±0.5% to ±2%, with transit-time meters for clean liquids offering the highest accuracy.

Ultrasonic Flow Meter Accuracy

Based on my technical knowledge:

Accuracy Factors

Performance Specifications

Type Accuracy Repeatability Flow Range Transit-Time ±0.5% ±0.15% 100:1 Doppler ±1-2% ±0.25% 50:1 Hybrid ±1% ±0.2% 75:1 Gas ±1-2% ±0.3% 30:1 Influencing Elements

- Installation quality

- Fluid conditions

- Pipe characteristics

- Environmental factors

Performance Optimization

Installation Requirements

- Straight pipe runs

- Mounting location

- Signal strength

- Calibration needs

Maintenance Factors

- Regular verification

- Signal monitoring

- Parameter updates

- Cleaning requirements

What is the Cost of Laser Doppler Flow Meter?

Underestimating the cost of advanced flow measurement technology can lead to budget shortfalls.

Laser Doppler flow meters typically cost between $15,000 to $50,000, depending on specifications and applications.

From my pricing experience:

Cost Breakdown

System Components

Component Cost Range Features Sensor $8,000-20,000 Laser Source Electronics $5,000-15,000 Processing Software $2,000-10,000 Analysis Installation $3,000-8,000 Setup Additional Costs

- Calibration services

- Training programs

- Maintenance contracts

- Spare parts

Value Considerations

Benefits Analysis

- High accuracy

- Non-intrusive

- Research grade

- Special applications

Operating Costs

- Power consumption

- Maintenance needs

- Calibration intervals

- Technical support

What is the Cost of Siemens Ultrasonic Flow Meter?

Choosing a flow meter solely based on brand name without considering specific needs can lead to unnecessary expenses.

Siemens ultrasonic flow meters range from $2,500 to $20,000, with clamp-on models starting at $3,500 and high-end custody transfer meters reaching $20,000.

Siemens Flow Meter Models

Drawing from my market knowledge:

Product Range

Model Comparison

Model Cost Range Application Basic $2,500-5,000 General Use Mid-Range $5,000-10,000 Industrial Premium $10,000-20,000 Custody Transfer Portable $4,000-8,000 Verification Feature Sets

- Communication options

- Accuracy levels

- Certification types

- Installation methods

Investment Analysis

Cost Factors

- Initial purchase

- Installation costs

- Operating expenses

- Maintenance needs

ROI Considerations

- Accuracy benefits

- Maintenance savings

- Energy efficiency

- Operational improvements

What Are the Disadvantages of an Ultrasonic Flow Meter?

Ignoring potential limitations can result in unexpected problems and reduced performance.

Main disadvantages include sensitivity to installation conditions, higher initial cost compared to traditional meters, and potential accuracy issues with challenging fluids.

Ultrasonic Flow Meter Limitations

From my troubleshooting experience:

Common Challenges

Technical Limitations

Issue Impact Solution Installation Accuracy Proper Setup Signal Loss Reliability Maintenance Cost Budget ROI Analysis Expertise Operation Training Application Constraints

- Pipe conditions

- Fluid properties

- Environmental factors

- Power requirements

Mitigation Strategies

Installation Solutions

- Proper planning

- Expert consultation

- Quality materials

- Regular maintenance

Operational Improvements

- Staff training

- Monitoring systems

- Preventive maintenance

- Performance validation

Conclusion

While ultrasonic flow meters require significant initial investment, their accuracy, reliability, and low maintenance costs often provide excellent long-term value when properly selected and installed.