Piping systems often require quick flow estimations – getting this wrong can lead to undersized equipment or dangerous overpressure situations.

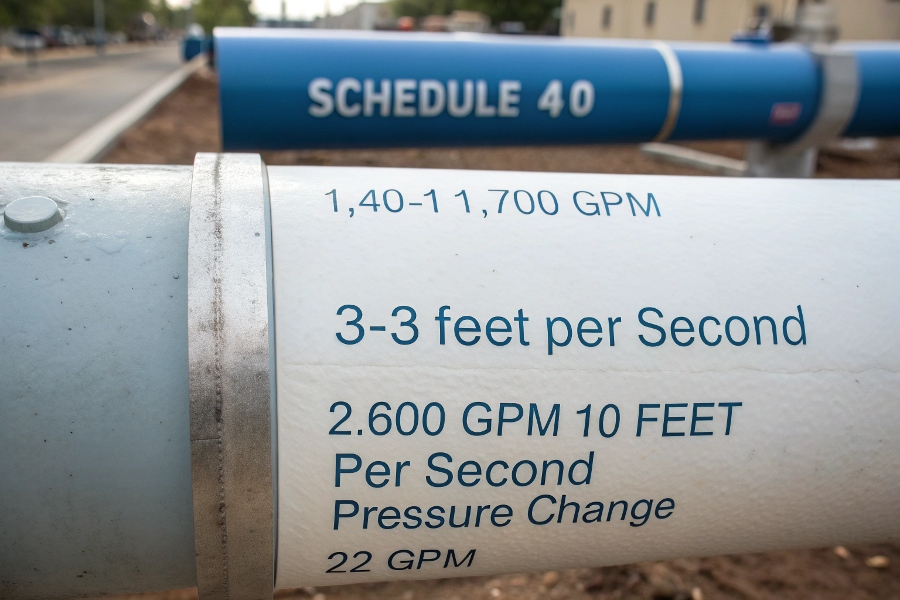

An 8-inch Schedule 40 pipe can carry approximately 1,140-1,700 GPM at typical water velocities of 3-5 ft/s. Maximum capacity reaches 2,600 GPM at 10 ft/s velocity (engineering limit). Actual flow depends on pressure, friction loss, and liquid properties – a 1 psi pressure change alters flow by ~22 GPM in this pipe size.

Flow In 8-Inch Pipe

Let’s break down the key calculations and practical considerations.

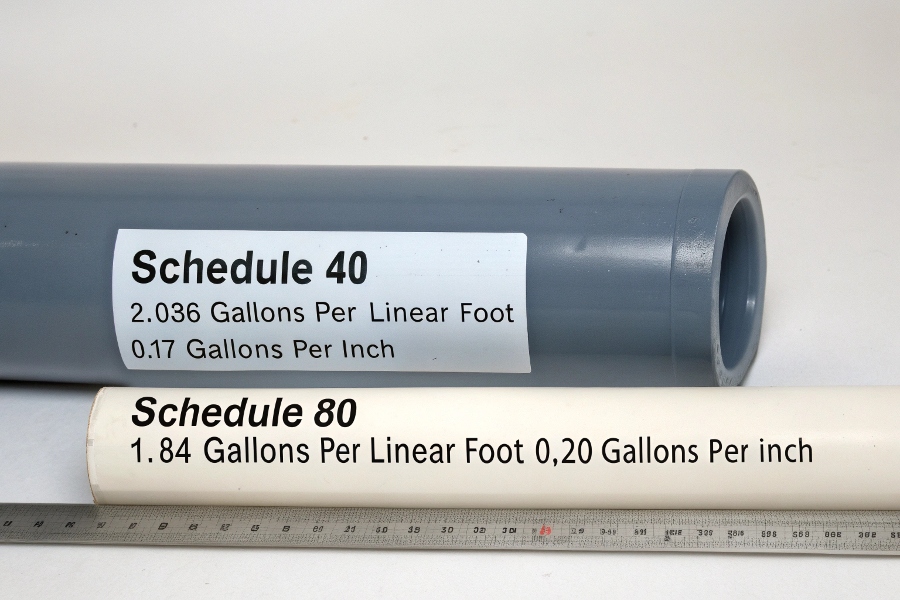

How Many Gallons per Foot in 8-Inch Pipe?

Pipe volume calculations are essential for system commissioning and chemical dosing.

An 8-inch Schedule 40 pipe holds 2.04 gallons per linear foot (0.17 gal/in). The exact volume is 2.036 gal/ft (0.226 cu.ft/ft) based on its 7.981-inch inner diameter. For Schedule 80 pipe (thicker walls), capacity reduces to 1.84 gal/ft (0.20 gal/in).

Pipe Volume Calculation

This baseline enables several practical calculations:

Pipe Volume Reference Table

| Pipe Specification | ID (inches) | gal/ft | gallons/100ft |

|---|---|---|---|

| Schedule 40 | 7.981 | 2.04 | 204 |

| Schedule 80 | 7.625 | 1.84 | 184 |

| Ductile Iron | 8.10 | 2.12 | 212 |

| Steel (standard) | 8.07 | 2.09 | 209 |

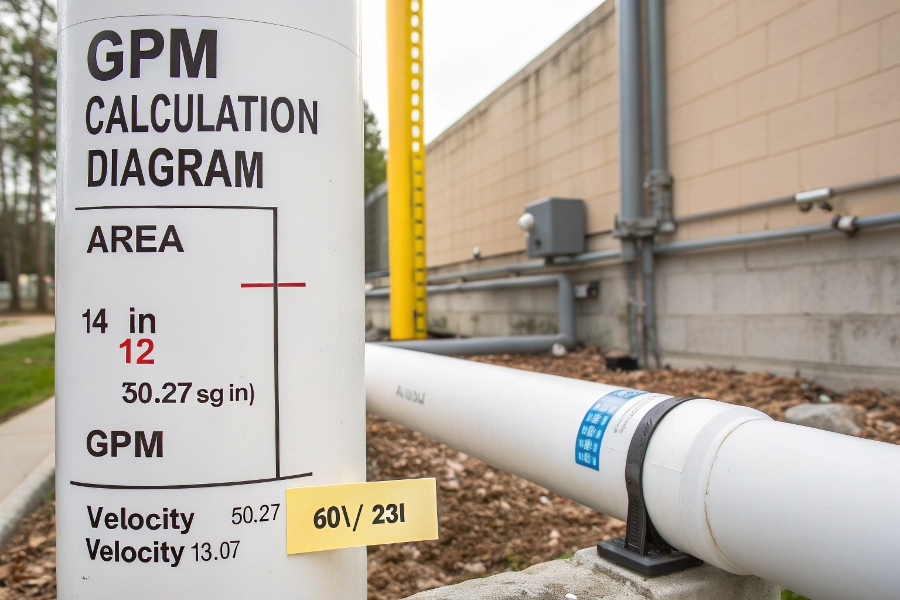

How Do You Calculate GPM Through a Pipe?

The fundamental flow equation combines pipe geometry with fluid velocity1.

Use the formula: GPM = (Velocity in ft/s × Pipe Area in sq.in × 60) / 231. For an 8-inch pipe: Area = π × (4 in)² = 50.27 sq.in → GPM = (Velocity × 50.27 × 60) / 231 ≈ Velocity × 13.07. This "13.07 multiplier" makes quick estimates easy – just multiply velocity (ft/s) by 13 to get approximate GPM.

GPM Calculation Diagram

Practical implementation requires understanding these components:

Flow Calculation Components

- Water: 3-5 ft/s (typical), 10 ft/s (max)

- Chemicals: 1-3 ft/s (viscosity-dependent)

- Slurries: 2-4 ft/s (solids suspension)

- 8" Schedule 40: 50.27 sq.in (standard reference)

- 8" Schedule 80: 45.66 sq.in (6.1% less flow)

- With 10% scale buildup: 42.4 sq.in (16% flow reduction)

- 1 cubic foot = 7.48 gallons

- 231 cubic inches = 1 gallon

How Many GPM Flows at 3.8 ft/s Velocity?

Real-world examples demonstrate the calculation process.

At 3.8 ft/s in an 8-inch Schedule 40 pipe: GPM = 3.8 × 13.07 = 49.67 GPM per ft/s → 3.8 × 49.67 = 188.6 GPM. More precisely: (3.8 × 50.27 × 60)/231 = 188.9 GPM. This matches common engineering charts showing ~190 GPM at this velocity.

Velocity-Flow Correlation

These calculations become especially valuable when troubleshooting:

Flow Rate Verification Example

| Observation | Calculation | Likely Issue |

|---|---|---|

| Measured: 130 GPM | (130/13.07) = 9.94 ft/s | Velocity exceed 10 ft/s limit → cavitation risk |

| Measured: 80 GPM @ 40 psi | (80/13.07) = 6.1 ft/s → 22psi/100ft loss | Excessive friction → check for obstructions |

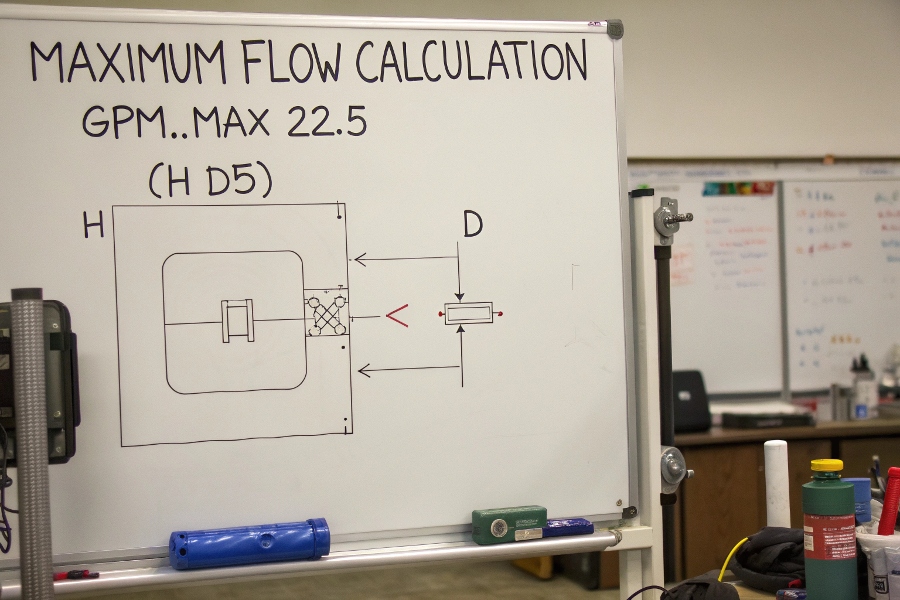

How to Calculate Maximum Flow Rate Through a Pipe?

System limits depend on physics, not just pipe dimensions.

The theoretical maximum (no friction): GPM_max = 22.5 × √(h × D⁵), where h=pressure head (ft), D=pipe diameter (inches). For 8-inch pipe at 100ft head: 22.5 × √(100 × 8⁵) ≈ 2,880 GPM. Reality limits to ~2,000 GPM due to friction (Hazen-Williams C=120).

Maximum Flow Calculation

Critical constraints determine safe operation:

Flow Rate Limit Factors

Hydraulic Constraints

- Joukowsky surge pressure (water hammer risk)

- NPSHa > NPSHr (cavitation prevention)

Material Limits

- Erosion velocity: 15 ft/s (metal), 7 ft/s (plastic)

- Vibration thresholds at high flow rates

Practical Standards

- AWWA C150: 5-7 ft/s design velocity

- ASME B31.1: 10 ft/s absolute maximum

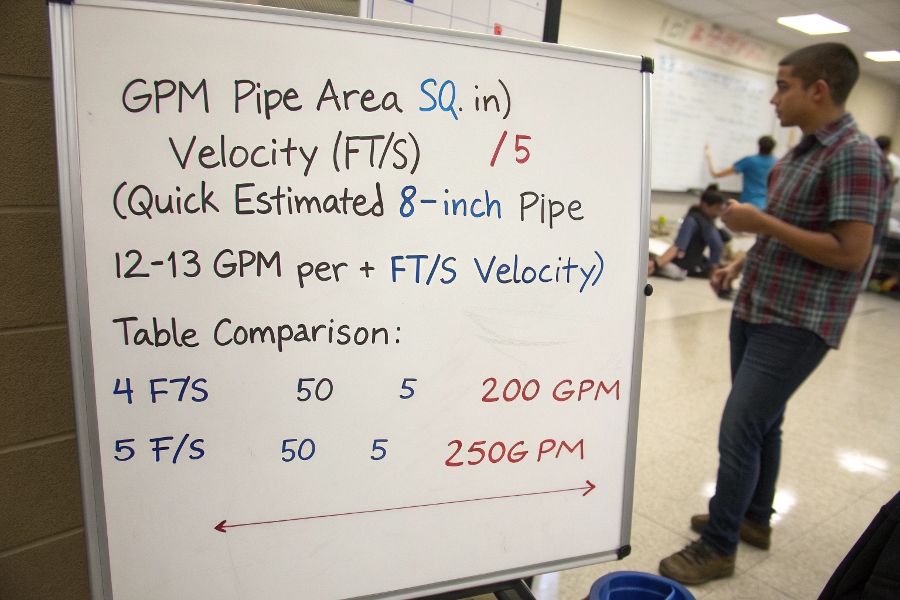

Field Estimation Techniques

Practical methods for quick checks without calculations.

**1) GPM ≈ Pipe Area (sq.in) × Velocity (ft/s) / 5 (quick estimate)

2) 8-inch pipe ≈ 12-13 GPM per 1 ft/s velocity (memorized multiplier)

3) Table comparison:

- 4 ft/s → ~50 × 4 = 200 GPM

- 5 ft/s → ~50 × 5 = 250 GPM**

Flow Estimation Aids

These approaches help validate flow meter readings:

Common Flow Rates for 8-Inch Pipe

| Application | Typical GPM | Velocity (ft/s) | Notes |

|---|---|---|---|

| Municipal water | 800-1,200 | 4-6 | Standard design range |

| Irrigation | 500-900 | 3-5 | Lower for sandy conditions |

| Fire protection | 1,500+ | 8-10 | Temporary high flow |

| Slurry transport | 300-600 | 2-4 | Prevents settling |

Conclusion

An 8-inch pipe typically handles 1,100-1,700 GPM in water applications, with absolute maximum near 2,600 GPM at 10 ft/s velocity. Always verify against system pressure, friction losses, and application requirements – proper flow estimation prevents both inadequate performance and dangerous overpressure situations.

This resource will help you understand the relationship between pipe design and fluid dynamics, essential for engineering applications. ↩

Understanding velocity ranges is crucial for accurate flow calculations in various applications. Explore this link for detailed insights. ↩

Area variations significantly impact flow rates, making it essential to grasp their effects for effective engineering solutions. Check this resource for more information. ↩

Knowing conversion factors is vital for accurate calculations in fluid dynamics. Discover more about these essential factors in this informative link. ↩