Wastewater plants lose thousands annually from inaccurate flow measurement – until they switch to EMF technology.

Electromagnetic flow meters (EMFs) excel in wastewater by measuring flow without moving parts (reducing clogging), handling dirty/abrasive fluids (0-60% solids), and maintaining ±0.5% accuracy despite changing conductivity. Their full-bore design prevents pressure loss while withstanding corrosive chemicals common in treatment processes.

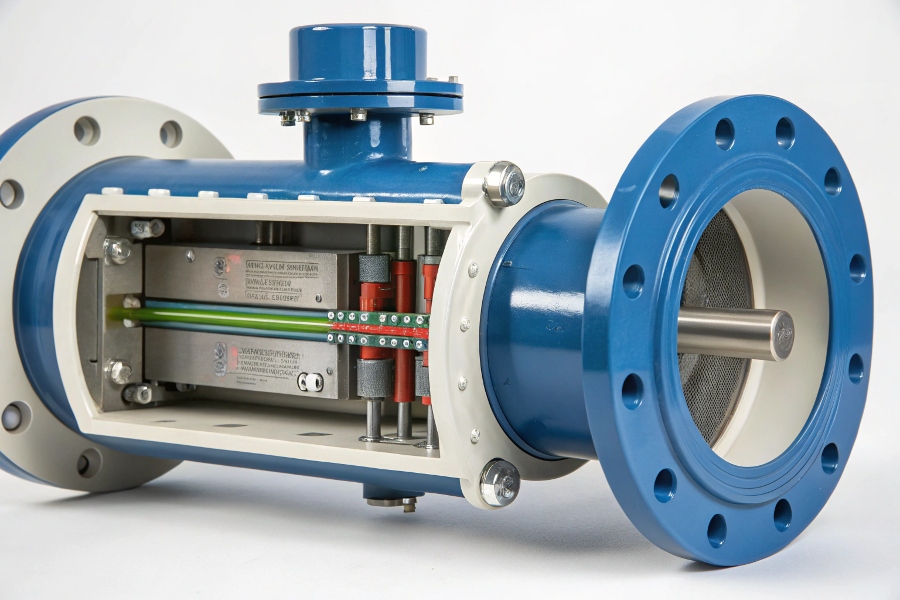

Wastewater EMF Installation

Here’s why EMFs dominate modern wastewater applications.

What Are the Advantages of an Electromagnetic Flow Meter?

No other technology combines these benefits for wastewater.

EMFs provide unobstructed flow paths (no fouling), measure forward/reverse flows equally well, require minimal straight pipe runs (3-5D), and work with any conductive liquid (>5μS/cm). Their liner options like hard rubber (HR) or polyurethane (PU) resist abrasion from sewage particles1 that destroy mechanical meters.

Full-Bore Design

Key operational benefits:

EMF vs Alternative Technologies

| Feature | EMF | Ultrasonic | Mechanical |

|---|---|---|---|

| No Pressure Drop | Yes | Yes | No |

| Handles Solids | Excellent | Fair | Clogs |

| Accuracy Stability | ±0.5% | ±1-2% | ±5%+ drift |

| Maintenance Interval | 5 years | 2 years | Monthly |

| Chemical Resistance | All liners | Limited | Rubber only |

Why Is Flow Measurement Important in Wastewater Treatment?

Every treatment stage depends on precise flow data.

Accurate flow measurement optimizes chemical dosing (saving 15-20% on coagulants), ensures proper aeration (reducing energy use2 by 30%), and prevents overloads in clarifiers. Municipal plants face fines if influent/effluent flows don’t match – EMFs provide the required ±1% custody transfer accuracy for compliance.

Flow Critical Processes

Measurement impact points:

Flow-Dependent Treatment Stages

Preliminary Treatment

- Bar screen throughput monitoring

- Grit removal efficiency

Primary Clarifiers

- Surface loading rate control

- Sludge blanket monitoring

Aeration Tanks

- Air blower adjustments

- MLSS concentration

Disinfection

- Chlorine contact time

- UV dose verification

What Is an Electromagnetic Flow Meter for Wastewater?

Specialized designs handle harsh conditions.

Wastewater EMFs feature ceramic electrode options3 (lasting 10+ years), dual-frequency excitation (handling bubbles/solids), and IP68/NEMA6P waterproof ratings. The ideal model has ground rings for poor conductivity fluids and Ni/CrMo alloy electrodes4 resisting H2S corrosion common in sewage.

Wastewater-Specific Features

Critical design elements:

Wastewater EMF Specifications

| Component | Standard Option | Wastewater Upgrade |

|---|---|---|

| Electrodes | 316SS | Hastelloy C-276 |

| Liner | PTFE | Polyurethane |

| Excitation | 6.25Hz | Dual 1/25Hz |

| Housing | IP65 | Submersible IP68 |

| Cable | PVC | PUR Oil-Resistant |

Which Flowmeter Is Suitable for Sewage Flow Measurement?

Four technologies compete – EMF wins.

While ultrasonic meters avoid contact, they fail with high solids (>5%). Mechanical meters (like turbine/PDP) clog within months. Coriolis handles solids but costs 5× more for large pipes. EMFs remain the standard – 85% of new sewage plants choose them for balanced performance and cost (1-3% of project budget).

Technology Selection

Selection criteria for sewage:

Sewage Flow Meter Decision Factors

Pipe Size Range

- EMF: 6"-120" typical

- Others limited above 48"

Solids Tolerance

- EMF: 0-60% suspended

- Others: <5-10%

Installation

- EMF: Any orientation

- Ultrasonic: Full pipe required

Lifecycle Cost

- EMF: $0.05/m³

- Coriolis: $0.22/m³

Installation Best Practices

Proper setup prevents 90% of issues:

| Guideline | Reason | Impact |

|---|---|---|

| Always install grounded | Prevents signal noise | Accuracy +0.2% |

| 3D upstream pipe | Flow profile stabilization | Repeatability ±0.1% |

| Avoid high points | Prevents air bubble traps | Prevents 50% faults |

| Use sacrificial anode | Extends electrode life | 3× longer service |

Conclusion

EMFs deliver unmatched wastewater measurement through robust designs that withstand harsh conditions while providing the precise flow data treatment processes require – making them the clear choice for modern plants.

Learn about the impact of sewage particles on flow meter durability and how to choose the right technology for longevity. ↩

Learning about energy reduction strategies can lead to more sustainable and cost-effective wastewater management. ↩

Learn how ceramic electrodes enhance the longevity and reliability of flow meters in challenging wastewater environments. ↩

Discover the benefits of using Ni/CrMo alloy electrodes, especially their resistance to corrosion in sewage systems. ↩