Many industrial processes struggle with inaccurate level measurements, leading to production inefficiencies and potential safety hazards.

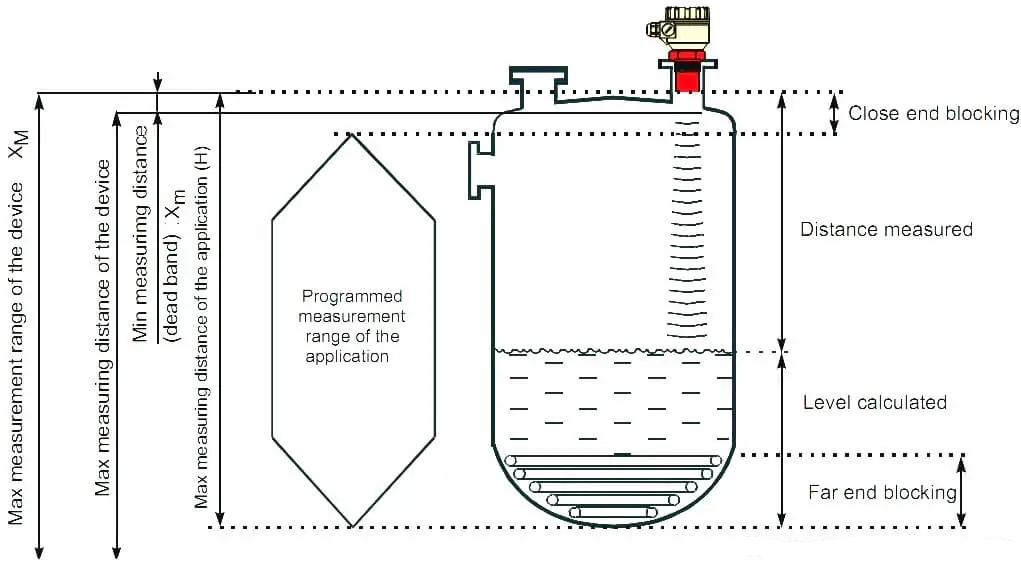

Ultrasonic level sensors work by emitting high-frequency sound waves (20-200 kHz) and measuring the time taken for echoes to return from the target surface. This time is converted into distance using the speed of sound.

Ultrasonic Level Sensor Operating Principle

Let me explain the working principles based on my experience in implementing these sensors across various industries.

How Does the Ultrasonic Sensor Work?

Understanding the basic operation helps in optimizing sensor performance.

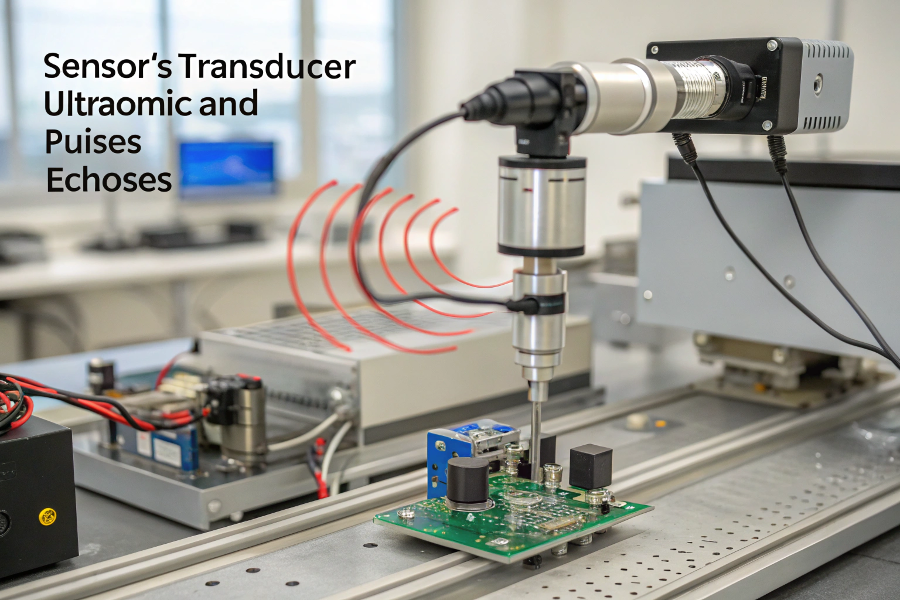

The sensor’s transducer emits ultrasonic pulses, receives their echoes, and calculates distance based on time-of-flight. The sensor processor then converts this into level measurements.

Ultrasonic Sensor Operation Diagram

From my technical experience:

Operating Sequence

Signal Generation

Phase Action Duration Emission Pulse generation Microseconds Travel Wave propagation Milliseconds Reception Echo detection Microseconds Processing Signal analysis Milliseconds Measurement Process

- Temperature compensation

- Echo verification

- Distance calculation

- Level conversion

Signal Processing

Echo Analysis

- Signal filtering

- Noise reduction

- Amplitude checking

- Quality verification

Output Generation

- Level calculation

- Volume conversion

- Alarm monitoring

- Data transmission

These processes ensure accurate and reliable measurements.

What Should I Avoid with Ultrasonic Level Sensors?

Installation mistakes can significantly impact measurement accuracy.

Avoid mounting sensors near obstacles, tank walls, or in areas with heavy vapor presence. Ensure proper temperature conditions and stable mounting to maintain accuracy.

Ultrasonic Sensor Installation Warnings

Based on my field experience:

Common Problems

Installation Issues

- Improper alignment

- Insufficient clearance

- Unstable mounting

- Cable routing errors

Environmental Challenges

- Temperature extremes

- Vapor interference

- Foam presence

- Turbulent surfaces

Prevention Measures

Installation Guidelines

- Proper mounting

- Adequate ventilation

- Cable protection

- Grounding requirements

Maintenance Practices

- Regular cleaning

- Signal monitoring

- Performance checks

- Calibration verification

Following these guidelines maximizes sensor reliability.

How Do Ultrasonic Sensors Detect?

Detection principles are key to proper implementation.

Ultrasonic sensors detect objects or liquid surfaces by analyzing echo characteristics. They measure time delays between transmitted and received signals to determine distance.

Ultrasonic Detection Method

Drawing from my implementation experience:

Detection Process

Wave Characteristics

Parameter Description Impact Frequency 20-200 kHz Resolution Power Variable Range Duration Microseconds Accuracy Beam angle 5-12 degrees Coverage Environmental Factors

- Air temperature

- Humidity levels

- Atmospheric pressure

- Surface conditions

Signal Analysis

Echo Processing

- Amplitude evaluation

- Time measurement

- Pattern recognition

- Interference filtering

Quality Checks

- Signal strength

- Echo consistency

- Noise levels

- Temperature effects

Understanding these aspects improves application success.

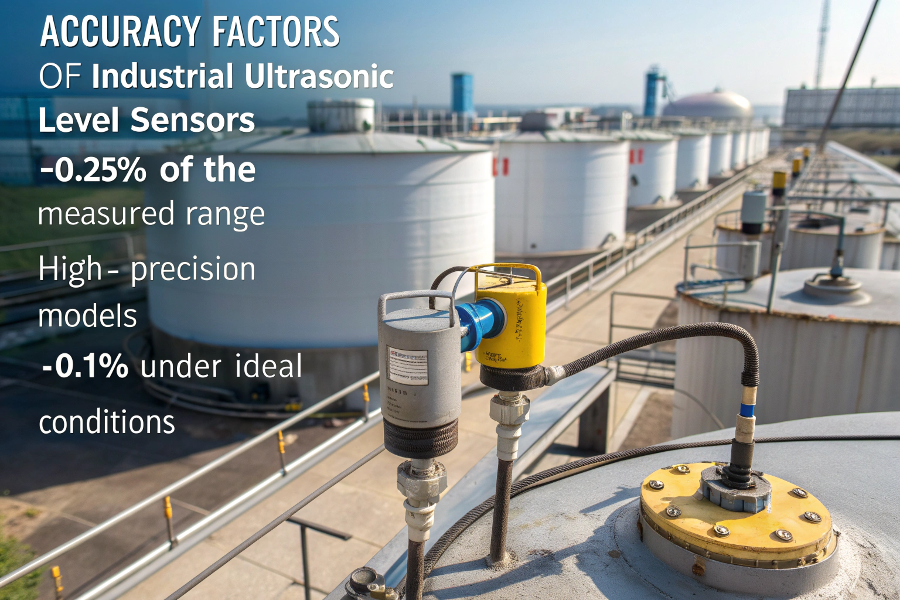

How Accurate Is an Ultrasonic Sensor?

Accuracy depends on various factors and proper implementation.

Most industrial ultrasonic level sensors achieve accuracies of ±0.25% of measured range, with some high-precision models reaching ±0.1% under optimal conditions.

Ultrasonic Sensor Accuracy Factors

From my measurement experience:

Accuracy Factors

Physical Parameters

Factor Impact Control Temperature High Compensation Vapor Medium Ventilation Turbulence High Stilling well Distance Medium Range selection Installation Effects

- Mounting stability

- Alignment precision

- Cable quality

- Grounding effectiveness

Optimization Methods

Calibration Procedures

- Zero point setting

- Span adjustment

- Temperature mapping

- Echo profiling

Maintenance Requirements

- Regular cleaning

- Signal monitoring

- Performance validation

- Environmental control

These practices ensure maximum accuracy.

Conclusion

Ultrasonic level sensors provide reliable measurements when properly understood and implemented. Success depends on correct installation, understanding operational principles, and maintaining optimal conditions for accurate detection.