Many engineers struggle to understand ultrasonic flow meter operation, leading to improper applications and measurement errors.

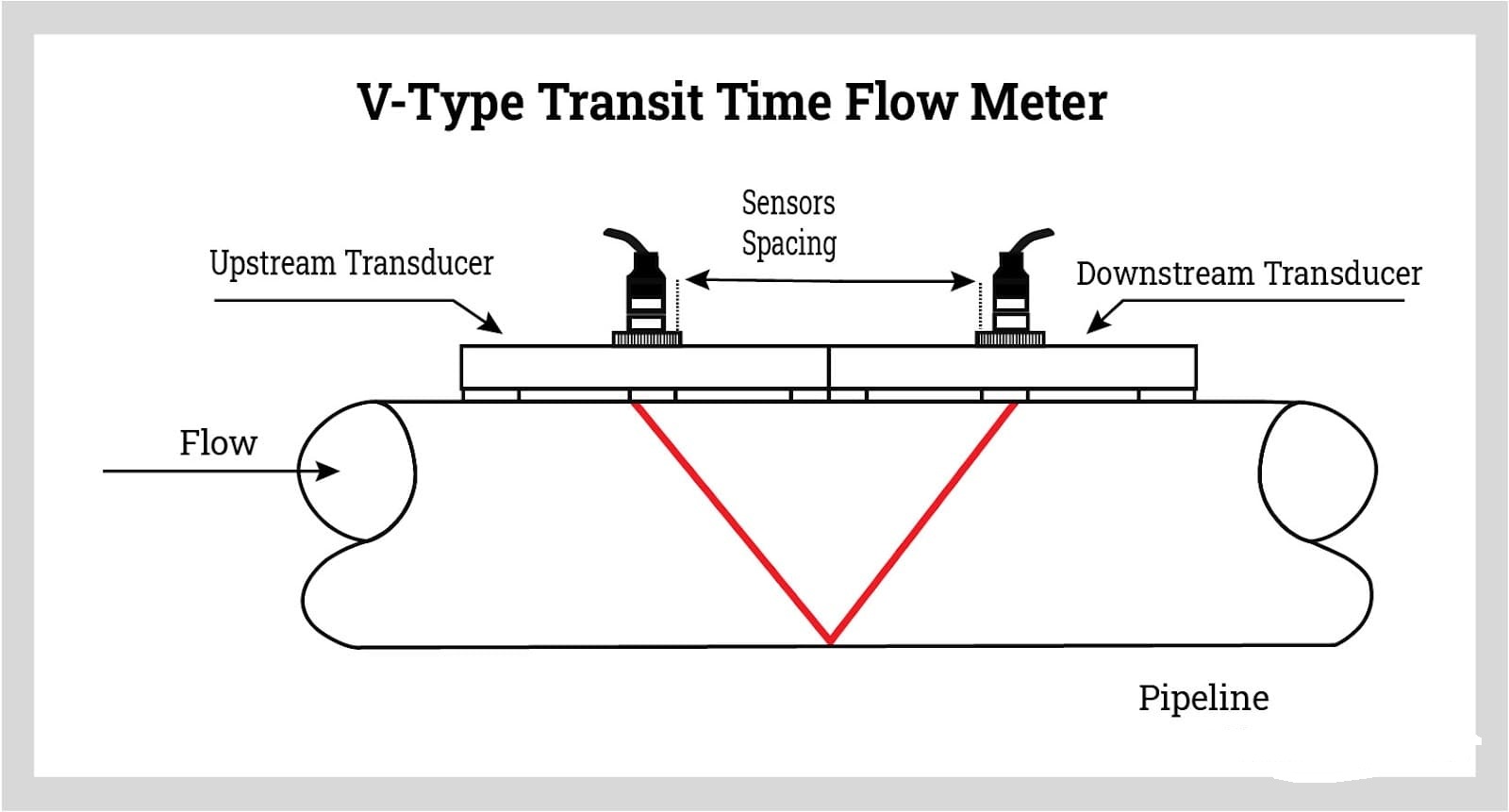

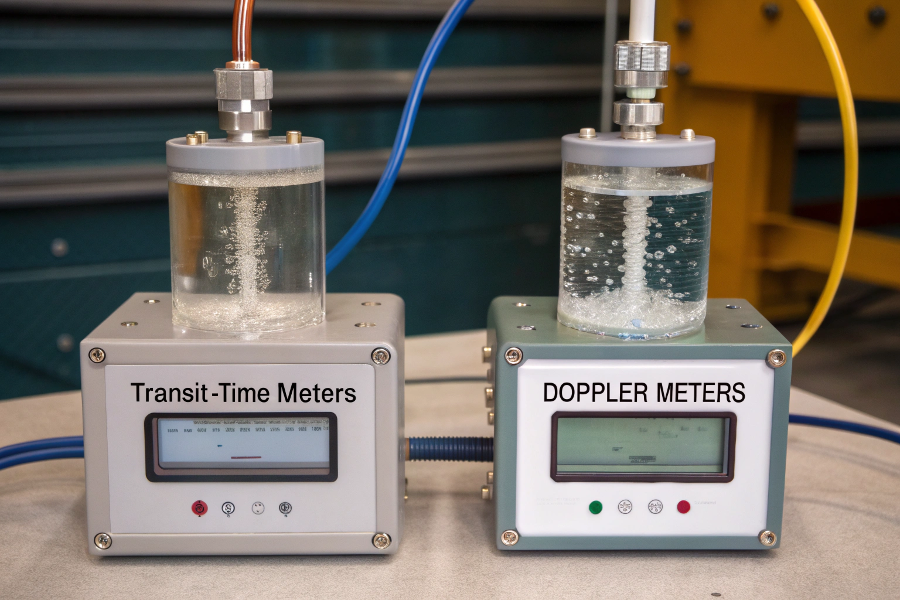

Ultrasonic flow meters work by sending sound waves through fluid and measuring either transit-time differences or frequency shifts to calculate flow velocity and volume.

Ultrasonic Flow Meter Basic Operation

Let me share my technical expertise to help you understand this technology better.

How Does a Ultrasonic Doppler Flow Meter Work?

Understanding Doppler technology is crucial for proper application in particle-containing fluids.

Doppler flow meters emit ultrasonic waves that reflect off particles in the fluid, measuring the frequency shift to determine flow velocity.

Doppler Flow Meter Working Principle

From my experience with Doppler systems:

Operating Principles

Key Components

Component Function Requirements Transmitter Signal generation Stable frequency Receiver Echo detection High sensitivity Particles Signal reflection Sufficient density Processor Data analysis Fast processing Signal Processing

- Frequency analysis

- Velocity calculation

- Flow computation

- Signal filtering

Application Considerations

Flow Conditions

- Particle content

- Fluid velocity

- Pipe conditions

- Installation location

Performance Factors

- Signal strength

- Particle distribution

- Flow profile

- Temperature effects

How to Use an Ultrasonic Flow Meter?

Incorrect installation and setup can lead to significant measurement errors.

Proper use involves selecting the right location, preparing the pipe surface, mounting transducers correctly, and configuring the meter with accurate parameters.

Ultrasonic Flow Meter Installation Guide

Based on my installation experience:

Installation Steps

Site Preparation

Step Action Purpose Location Selection Check straight runs Flow profile Surface Preparation Clean and mark Good contact Parameter Collection Measure pipe Accurate setup Tool Organization Gather equipment Efficient install Setup Process

- Mount transducers

- Connect cables

- Configure settings

- Verify operation

Verification Methods

System Checks

- Signal strength

- Zero flow test

- Flow direction

- Data stability

Maintenance Requirements

- Regular inspection

- Signal monitoring

- Coupling check

- Calibration verification

How Does an Ultrasonic Level Meter Work?

Level measurement errors can cause serious process control issues.

Ultrasonic level meters work by emitting sound waves that reflect off liquid surfaces, measuring the time taken for echoes to return to calculate distance.

Ultrasonic Level Meter Operation

Drawing from my technical knowledge:

Measurement Principles

Core Components

Component Function Critical Factors Transducer Wave emission Clear path Controller Time measurement Accurate timing Temperature Compensation Environmental Display Reading output Clear visibility Signal Processing

- Echo detection

- Distance calculation

- Level computation

- Error compensation

Application Guidelines

Installation Requirements

- Mounting position

- Dead band

- Beam angle

- Environmental conditions

Performance Optimization

- Signal quality

- Temperature compensation

- Interference elimination

- Regular maintenance

How Accurate is the Ultrasonic Flow Meter?

Accuracy concerns often prevent users from fully trusting ultrasonic measurement.

Modern ultrasonic flow meters can achieve accuracy up to ±0.5% of reading, with typical systems operating at ±1-2% under proper conditions.

Ultrasonic Flow Meter Accuracy Factors

From my testing experience:

Accuracy Factors

Critical Parameters

Factor Impact Optimization Installation Major Proper setup Flow Profile Significant Straight runs Signal Quality Critical Good coupling Calibration Essential Regular checks Environmental Effects

- Temperature changes

- Pressure variations

- Fluid properties

- External noise

Performance Optimization

Setup Requirements

- Correct positioning

- Parameter accuracy

- Signal strength

- Zero calibration

Maintenance Needs

- Regular inspection

- Signal monitoring

- Parameter verification

- Recalibration schedule

Conclusion

Understanding ultrasonic flow meter operation principles, proper installation methods, and accuracy factors is crucial for achieving reliable and accurate measurements in your applications.