Engineers often struggle to understand the complex physics behind flow measurement technologies.

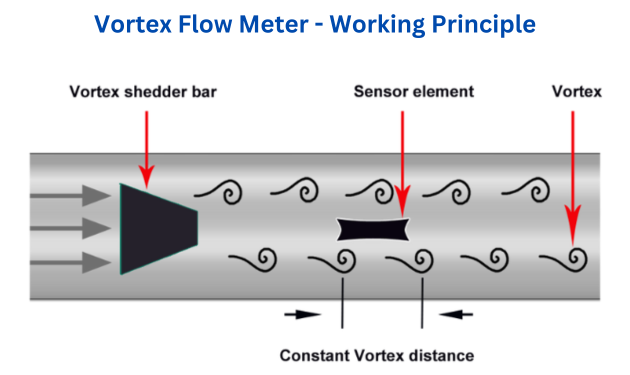

A vortex flow meter works by creating alternating vortices (von Kármán vortex street) behind a bluff body, where the frequency of these vortices is proportional to flow velocity.

Vortex Flow Meter Working Principle

Let me explain how this fascinating technology works based on my years of experience in flow measurement.

What is the Working Principle of a Flow Meter?

Many process engineers struggle with selecting the right flow meter due to unclear understanding of measurement principles.

Flow meters measure fluid movement through pipes using various physical principles like differential pressure, velocity, or mass flow, converting these measurements into usable flow data.

Flow Measurement Principles

From my technical background:

Measurement Methods

Common Principles

Method Principle Application Differential Pressure Pressure drop Universal Velocity Direct speed Clean fluids Mass Flow Direct mass Gas/Steam Volumetric Direct volume Liquids Key Parameters

- Flow patterns

- Fluid properties

- Operating conditions

- Installation requirements

Signal Processing

Measurement Chain

- Primary element

- Sensor technology

- Signal conversion

- Data processing

Output Types

- Analog signals

- Digital communication

- Local display

- Remote monitoring

What Sensor is Used in a Vortex Flow Meter?

Selecting the right sensor technology is crucial for accurate vortex flow measurement.

Vortex flow meters typically use piezoelectric sensors to detect pressure fluctuations caused by vortex shedding, converting them into electrical signals.

Vortex Flow Meter Sensors

Based on my hands-on experience:

Sensor Technologies

Sensor Types

Type Operation Benefits Piezoelectric Pressure to voltage Fast response Capacitive Position sensing High stability Strain gauge Force detection Robust design Electronic Digital output Smart features Design Considerations

- Temperature limits

- Pressure ratings

- Material compatibility

- Installation method

Signal Processing

Electronics Design

- Amplification

- Filtering

- Digitization

- Processing algorithms

Output Features

- Flow calculation

- Temperature compensation

- Pressure correction

- Diagnostic functions

What is the Principle of a Vortex?

Understanding vortex formation is essential for proper meter selection and installation.

Vortices form when fluid flows past a bluff body, creating alternating low-pressure zones that generate a stable pattern of swirling flow known as the von Kármán vortex street.

Vortex Formation Process

Drawing from my fluid dynamics knowledge:

Vortex Physics

Formation Process

Stage Description Impact Separation Flow splits Initial vortex Rotation Swirl develops Frequency generation Shedding Vortex release Measurement signal Pattern Street forms Stable measurement Influencing Factors

- Reynolds number

- Fluid velocity

- Bluff body shape

- Pipe conditions

Design Optimization

Bluff Body Design

- Shape optimization

- Size selection

- Material choice

- Surface finish

Flow Conditioning

- Upstream requirements

- Downstream effects

- Installation position

- Flow stabilization

What are the Advantages of a Vortex Flow Meter?

Understanding benefits helps in making informed meter selection decisions.

Vortex flow meters offer high accuracy, no moving parts, minimal maintenance, and wide rangeability, making them ideal for many industrial applications.

Vortex Flow Meter Advantages

From my field experience:

Key Benefits

Technical Advantages

Feature Benefit Impact No moving parts Low maintenance Cost savings Wide range Flexibility Versatility High accuracy Reliable data Process control Digital output Smart features Integration Application Benefits

- Universal fluid types

- Temperature resistant

- Pressure capable

- Cost effective

Practical Considerations

Installation Benefits

- Simple setup

- Minimal maintenance

- Long-term stability

- Easy troubleshooting

Operational Advantages

- Energy efficiency

- Process optimization

- Quality control

- Cost reduction

Conclusion

Vortex flow meters combine simple physics principles with modern sensor technology to provide reliable, accurate flow measurement across a wide range of industrial applications.