Engineers often struggle to choose the right flow meter for their applications, especially when dealing with steam and gas measurements.

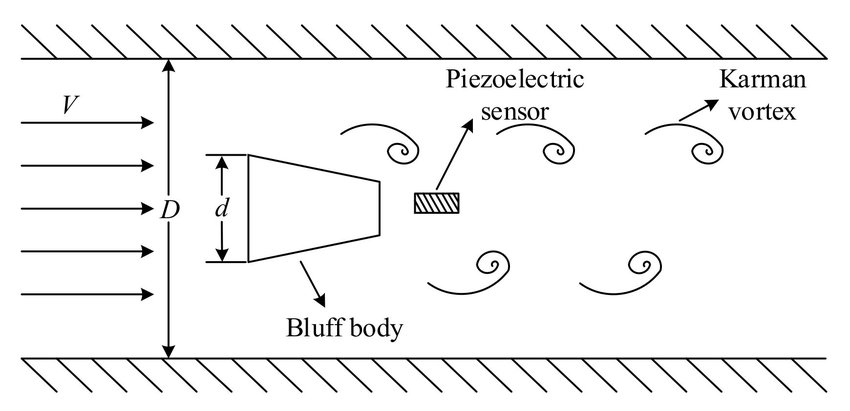

A vortex flow meter works by creating and measuring vortices in the fluid flow. When fluid passes a bluff body, it creates alternating vortices whose frequency is proportional to the flow rate.

Vortex Flow Meter Working Principle

Let me explain how this fascinating technology works based on my experience with industrial applications.

What Is The Working Principle Of A Vortex Flow Meter?

Understanding the vortex principle is crucial for proper application and maintenance.

The meter uses the von Kármán effect, where fluid flowing past a bluff body creates alternating vortices. The frequency of these vortices is directly proportional to flow velocity.

Vortex Formation Process

Here’s a detailed breakdown of the principle:

Vortex Formation Process

Key Components

Component Function Impact Bluff Body Creates vortices Primary measurement element Sensor Detects vortices Converts to electrical signal Electronics Signal processing Calculates flow rate Housing Protection Environmental shield Operating Parameters

- Reynolds number requirements

- Minimum flow velocity

- Maximum flow velocity

- Fluid properties impact

Measurement Process

Signal Generation

- Vortex creation

- Frequency detection

- Signal amplification

- Digital conversion

Calculation Methods

- Flow velocity calculation

- Volume flow computation

- Temperature compensation

- Pressure compensation

What Is The Difference Between Mass Flow Meter And Vortex Flow Meter?

This is a crucial distinction for selecting the right meter for your application.

Mass flow meters directly measure fluid mass flow rate using Coriolis force, while vortex meters measure volumetric flow rate through vortex shedding frequency.

Mass vs Vortex Flow Meter Comparison

From my installation experience:

Technical Differences

Measurement Principles

Feature Mass Flow Meter Vortex Flow Meter Primary measurement Direct mass flow Volumetric flow Accuracy Higher Lower Cost Higher Lower Installation requirements More strict Less strict Application Considerations

- Process conditions

- Fluid properties

- Accuracy requirements

- Budget constraints

Selection Criteria

Process Requirements

- Fluid type

- Flow range

- Operating conditions

- Required accuracy

Installation Factors

- Space requirements

- Straight run needs

- Maintenance access

- Cost considerations

What Are The Limitations Of Vortex Flow Meter?

Understanding limitations helps prevent misapplication and ensures reliable measurement.

Vortex meters require minimum flow velocity, stable Reynolds numbers, and sufficient straight pipe runs. They’re not suitable for low-flow applications or highly viscous fluids.

Vortex Flow Meter Limitations

Based on my field experience:

Operating Limitations

Flow Conditions

Limitation Impact Solution Low flow No measurement Size down High viscosity Poor performance Alternative meter Pulsating flow Erratic readings Damping Two-phase flow Inaccurate measurement Different technology Installation Requirements

- Upstream straight run

- Downstream straight run

- Mounting orientation

- Vibration concerns

Application Restrictions

Process Limitations

- Minimum Reynolds number

- Maximum Reynolds number

- Temperature limits

- Pressure limits

Environmental Factors

- Ambient temperature

- Vibration levels

- EMI interference

- Weather protection

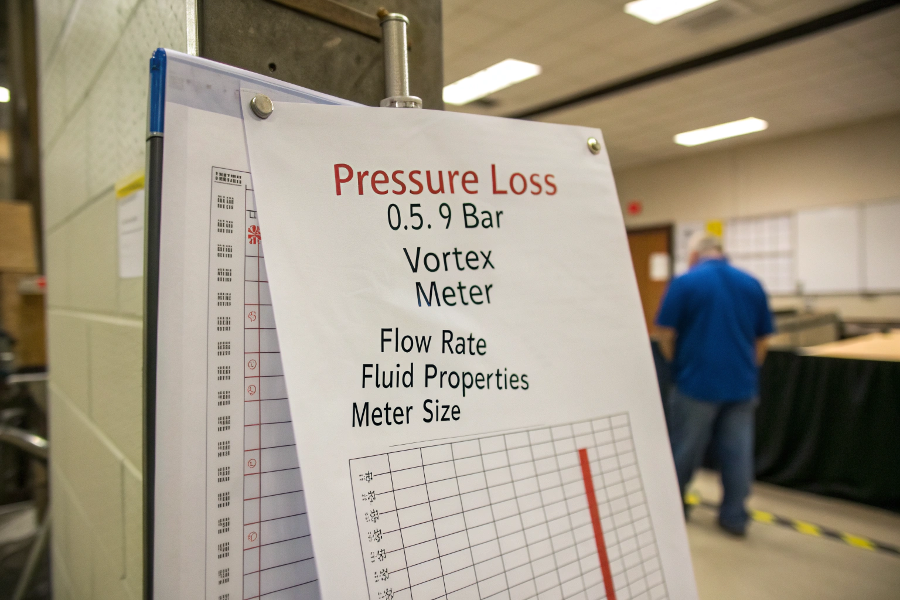

How Much Pressure Loss Is A Vortex Flowmeter?

Pressure loss affects system efficiency and operating costs.

Typical pressure loss in a vortex meter ranges from 0.5 to 2 bar, depending on flow rate, fluid properties, and meter size.

%(percentage)pressure-loss-chart

Vortex Flow Meter Pressure Loss Chart

Let me explain the factors affecting pressure loss:

Pressure Loss Factors

Design Parameters

Factor Impact Consideration Meter size Inverse relationship Proper sizing Flow rate Squared relationship Operating range Fluid density Direct relationship Process conditions Beta ratio Complex relationship Optimization Operating Conditions

- Flow velocity

- Fluid viscosity

- Temperature effects

- Pressure effects

Optimization Methods

Design Considerations

- Size selection

- Installation position

- Flow conditioning

- Bypass options

Operational Factors

- Regular maintenance

- Clean fluid

- Stable conditions

- Proper installation

Conclusion

Vortex flow meters offer reliable measurement for many applications, but success depends on understanding their principles, limitations, and proper installation requirements.