Float switch failures can lead to devastating equipment damage, costly downtime, and potentially dangerous overflow situations.

To test a float switch, check its electrical continuity, physical movement, and proper mounting position. A working float switch should show continuity when activated and open circuit when not.

Float Switch Testing Methods

Let me share some practical troubleshooting tips from my experience working with various float switch installations.

How to Test if a Float Switch is Bad?

Many maintenance technicians struggle with identifying faulty float switches, leading to unnecessary replacements or missed failures.

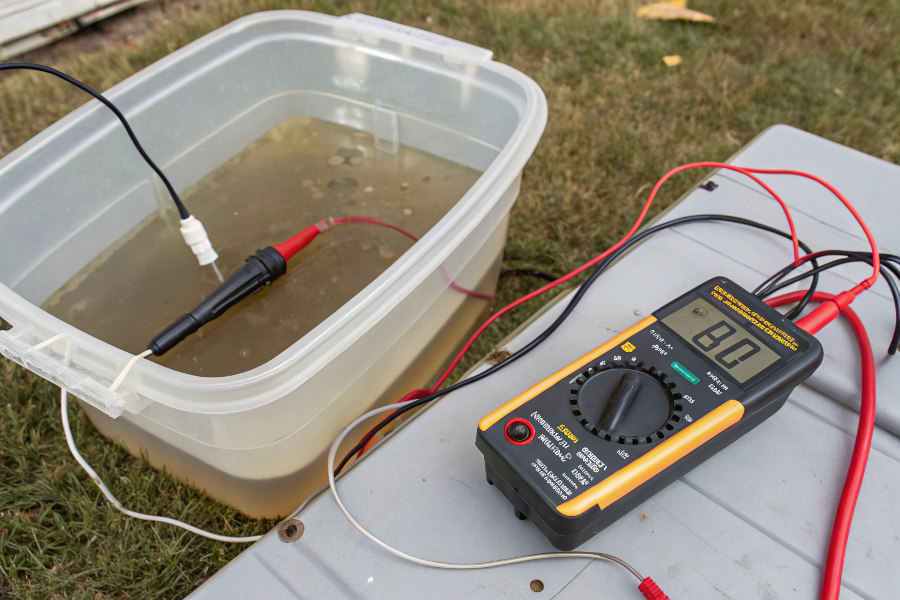

Test a float switch using a multimeter set to continuity mode – it should read zero ohms when activated and infinite when not. Also check for free movement and proper orientation.

Float Switch Testing Procedure

Based on my field experience:

Testing Procedure

Electrical Testing

Step Action Expected Result Power Off Disconnect power Safety first Continuity Check with meter Changes with position Resistance Measure ohms Within specs Insulation Check for shorts No leakage Physical Inspection

- Free movement check

- Damage assessment

- Mounting verification

- Cable condition review

Common Issues

Mechanical Problems

- Stuck float

- Damaged pivot

- Incorrect mounting

- Build-up interference

Electrical Issues

- Corroded contacts

- Broken wires

- Water ingress

- Failed switch

These checks help identify problems quickly.

Why is My Float Switch Not Working?

A non-functioning float switch can result from various issues that aren’t always obvious at first glance.

Float switch failures commonly stem from mechanical obstruction, electrical problems, improper installation, or damage from the process environment.

Common Float Switch Problems

Drawing from my troubleshooting experience:

Problem Sources

Environmental Factors

Issue Cause Solution Buildup Process material Regular cleaning Corrosion Chemical attack Material upgrade Temperature Process heat Proper selection Vibration Equipment motion Better mounting Installation Issues

- Wrong orientation

- Incorrect wiring

- Poor mounting

- Cable strain

Solution Approach

Systematic Check

- Visual inspection

- Movement test

- Electrical verification

- Environmental review

Preventive Measures

- Regular maintenance

- Proper protection

- Environment monitoring

- Documentation

These steps ensure thorough problem solving.

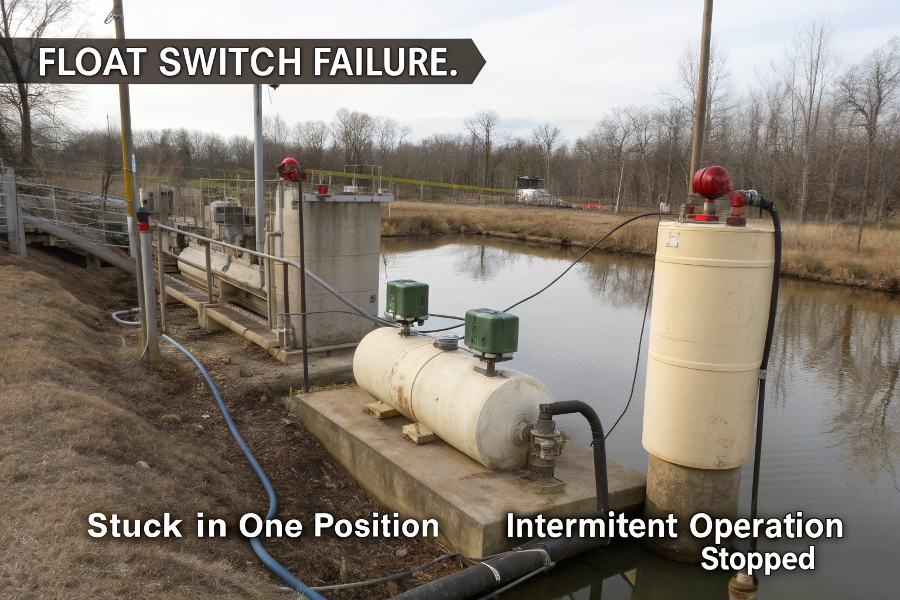

What Happens When a Float Switch Goes Bad?

Understanding float switch failure modes helps prevent serious consequences in your process.

When a float switch fails, it can either stick in one position, provide intermittent operation, or completely stop functioning, potentially causing equipment damage or overflow conditions.

Float Switch Failure Modes

From my system design experience:

Failure Modes

Common Failures

Type Impact Risk Level Stuck Float No level change High Contact Failure Erratic operation Medium Cable Break Complete failure High Seal Failure Gradual degradation Medium System Effects

- Pump damage

- Tank overflow

- Process interruption

- Safety risks

Prevention Strategy

Maintenance Program

- Regular inspection

- Cleaning schedule

- Performance testing

- Documentation

Design Considerations

- Redundancy needs

- Backup systems

- Alarm integration

- Access provision

These strategies minimize failure impacts.

How Many Ohms Should a Float Switch Have?

Proper resistance measurement is crucial for verifying float switch functionality.

A working float switch should show near zero ohms (0-1Ω) when closed and infinite resistance when open. Any other readings indicate potential problems.

Float Switch Resistance Measurement

Based on my maintenance experience:

Resistance Testing

Measurement Guidelines

Condition Reading Action Switch Closed 0-1Ω Normal Switch Open Infinite Normal High Resistance >1Ω Investigate Inconsistent Varies Replace Testing Procedure

- Use proper meter

- Verify settings

- Check both positions

- Record results

Interpretation Guide

Reading Analysis

- Normal range

- Warning signs

- Failure indicators

- Trending changes

Follow-up Actions

- Clean contacts

- Check connections

- Replace if needed

- Document findings

These measurements ensure reliable operation.

Conclusion

Effective float switch troubleshooting requires systematic testing, proper understanding of failure modes, and regular maintenance to ensure reliable operation and prevent system failures.