Incorrect sewage pipe calculations can lead to costly overflows, backups, and environmental hazards.

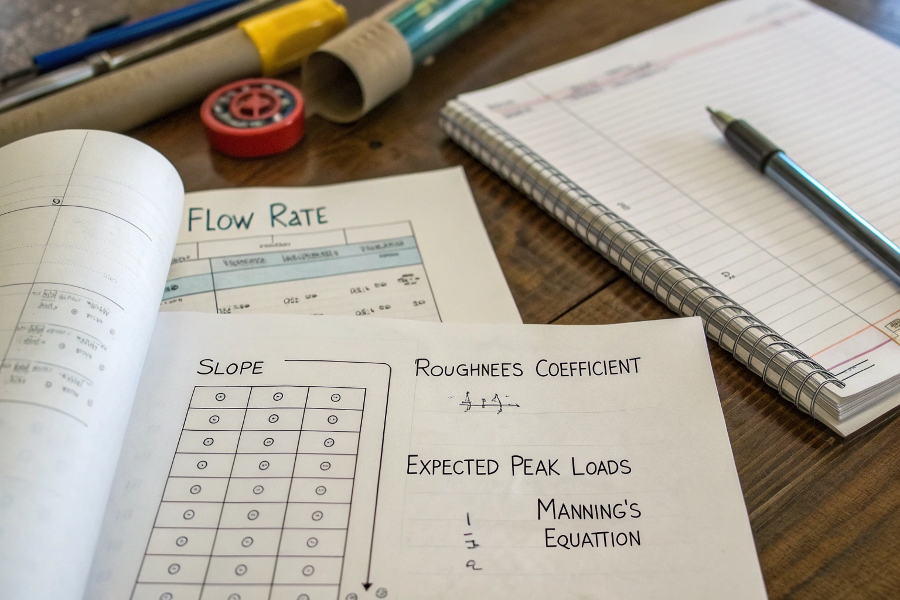

Sewage pipe calculations involve determining pipe diameter based on flow rate, slope, roughness coefficient, and expected peak loads using Manning’s equation.

Sewage Pipe Calculation Methods

Let me share my experience in designing and implementing sewage systems across various projects.

How To Calculate Sewer Pipe Size?

Many engineers struggle with properly sizing sewer pipes, leading to system failures.

Sewer pipe size calculation requires considering peak flow rates, minimum velocity requirements (2 ft/s), and Manning’s equation while accounting for future capacity needs.

Sewer Pipe Sizing Guide

From my engineering experience:

Sizing Methodology

Key Factors

Parameter Standard Range Importance Considerations Flow Rate1 2-8 ft/s Critical Prevents settling Slope 1-2% Essential Gravity flow Roughness 0.009-0.015 Important Material dependent Capacity 50-75% full Design standard Peak flows Design Considerations

- Population served

- Future growth

- Industrial inputs

- Infiltration rates

Calculation Process

Load Assessment

- Peak flow rates

- Usage patterns

- Safety factors

- System redundancy

Technical Analysis

- Hydraulic calculations2

- Material selection

- Installation requirements

- Maintenance access

How To Calculate Flow In A Sewer Pipe?

Accurate flow calculation is essential for proper sewer system operation.

Sewer pipe flow is calculated using Manning’s equation, which considers pipe diameter, slope, roughness coefficient, and flow depth.

From my flow measurement experience:

Calculation Methods

Manning’s Equation Components

Parameter Symbol Typical Range Impact Roughness n 0.009-0.015 Flow resistance3 Hydraulic radius4 R Varies Flow capacity Slope S 1-2% Flow velocity Area A Pipe dependent Volume capacity Flow Considerations

- Partial flow conditions

- Peak flow rates

- Minimum velocities

- Maximum capacities

Implementation Process

Data Collection

- Pipe characteristics

- Flow measurements

- System conditions

- Usage patterns

Analysis Steps

- Calculations verification

- Field measurements

- Performance monitoring

- System adjustments

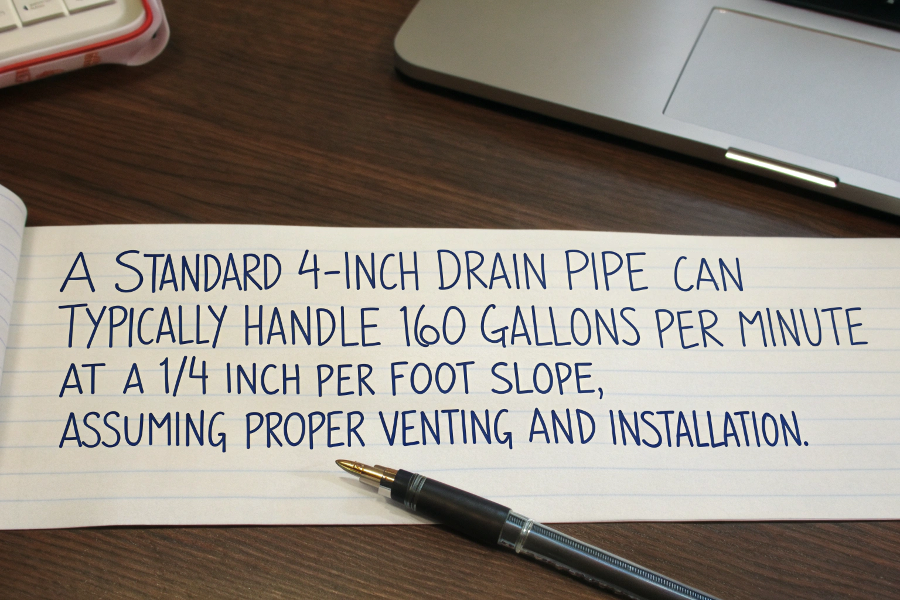

How Many GPM Can A 4" Drain Handle?

Understanding drain capacity is crucial for preventing system overload.

A standard 4-inch drain pipe can typically handle 160 GPM (gallons per minute) at a 1/4 inch per foot slope, assuming proper venting and installation.

4-inch Drain Capacity Chart

Based on my plumbing expertise:

Capacity Analysis

Flow Rates

Slope Capacity (GPM) Velocity (ft/s) Usage Type 1/8"/ft 90 2.2 Residential 1/4"/ft 160 3.0 Commercial 1/2"/ft 220 4.2 Industrial 1"/ft 320 5.8 Heavy duty Performance Factors

- Pipe material

- Installation quality

- Maintenance condition

- Venting adequacy

Implementation Guidelines

Design Considerations

- Maximum load scenarios

- Flow variations

- System redundancy

- Emergency overflow

Installation Requirements

- Proper slope

- Support spacing

- Joint methods

- Access points

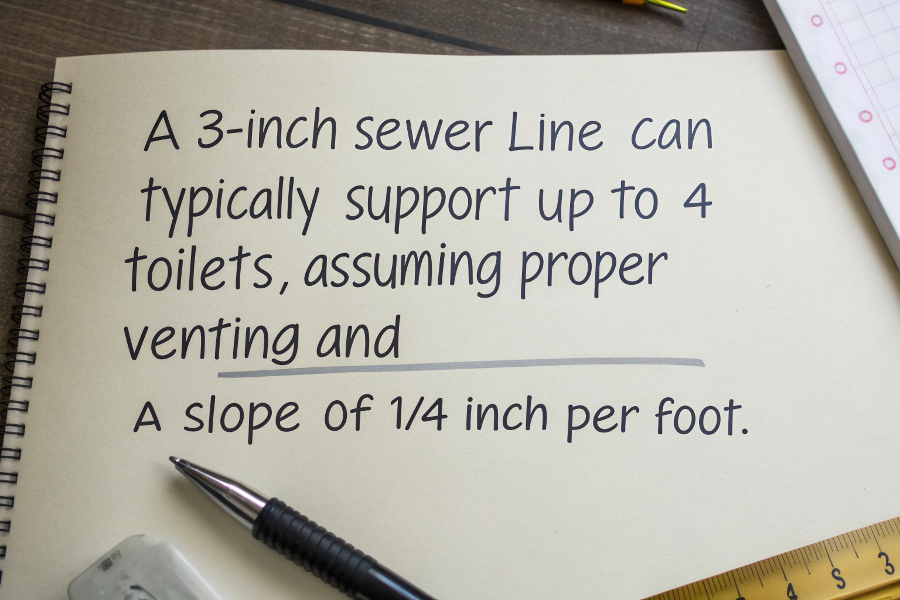

How Many Toilets Can You Put On A 3 Inch Sewer Line?

Proper toilet load calculation prevents costly backups and overflows.

A 3-inch sewer line can typically support up to 4 toilets, assuming proper venting and a slope of 1/4 inch per foot.

3-inch Line Toilet Capacity

Drawing from my installation experience:

Load Planning

Capacity Factors

Number of Toilets Required Slope DFU Load Limitations 1-2 1/8"/ft 6 DFU Residential 3-4 1/4"/ft 12 DFU Maximum load 4+ Not recommended >12 DFU Upgrade needed Commercial 4" required Varies Code dependent System Requirements

- Proper venting

- Clean-out access

- Support spacing

- Material selection

Installation Guidelines

Setup Requirements

- Slope verification

- Venting configuration

- Support methods

- Testing procedures

Maintenance Considerations

- Access points

- Cleaning schedule

- Inspection routine

- Emergency protocols

Conclusion

Successful sewage pipe calculation requires careful consideration of flow rates, pipe sizes, and installation requirements, combined with proper maintenance and monitoring to ensure long-term system performance.

Understanding flow rate is crucial for effective hydraulic design, ensuring systems function properly and prevent issues like settling. ↩

Exploring hydraulic calculations will enhance your design skills, ensuring efficient and reliable systems tailored to specific needs. ↩

Exploring flow resistance helps in designing efficient piping systems and improving fluid transport. ↩

Understanding the hydraulic radius is crucial for optimizing flow capacity in various engineering applications. ↩