Many instrument engineers struggle with accurate differential pressure calculations, leading to measurement errors.

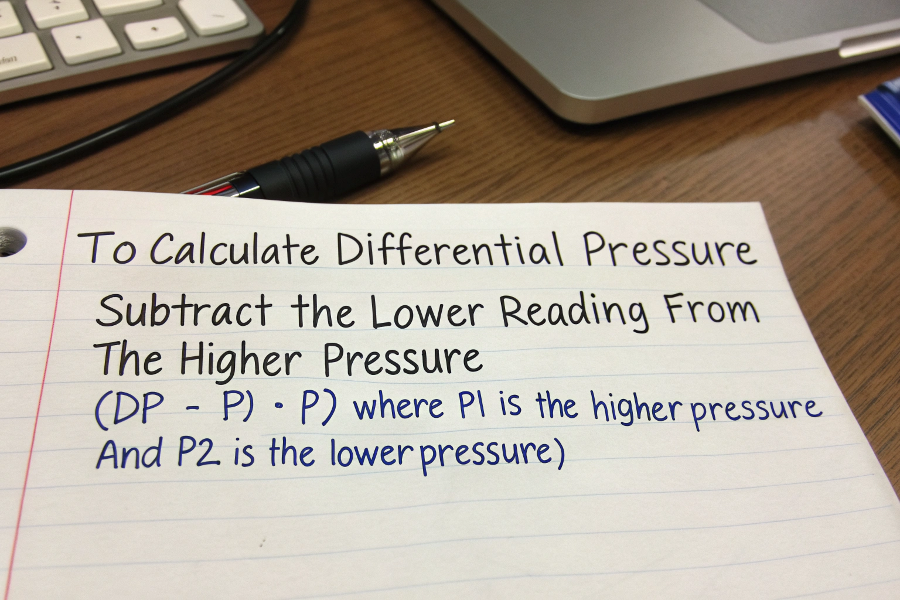

To calculate differential pressure, subtract the lower pressure reading from the higher pressure reading (DP = P1 – P2), where P1 is the higher pressure and P2 is the lower pressure.

Differential Pressure Calculation Basics

Differential Pressure Calculation Basics

Let me share our experience in calculating differential pressure for various applications.

How Do You Calculate Differential Pressure?

Incorrect DP calculations can lead to serious measurement errors and process control issues.

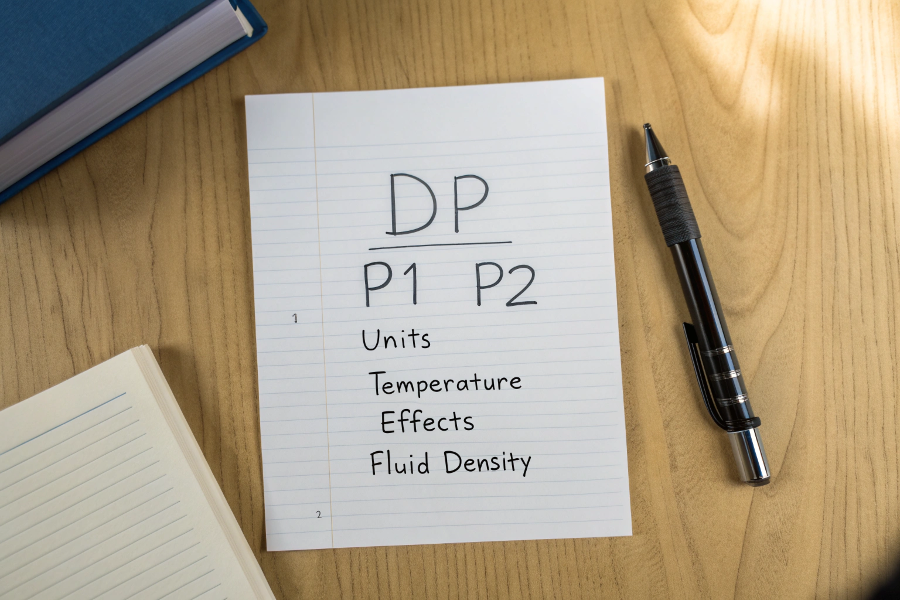

The basic differential pressure calculation follows DP = P1 – P2, but you must consider units, temperature effects, and fluid density for accurate results.

DP Calculation Factors

From our practical experience:

Basic Calculation Steps

Pressure Measurements

Parameter Description Units P1 (High) Upstream pressure PSI/Bar/kPa P2 (Low) Downstream pressure PSI/Bar/kPa DP Differential pressure PSI/Bar/kPa Height Elevation difference Feet/Meters Correction Factors

- Temperature effects

- Static pressure

- Fluid density

- Elevation changes

Advanced Considerations

Environmental Factors

- Ambient temperature

- Process temperature

- Installation height

- Atmospheric pressure

Application Requirements

- Accuracy needs

- Range requirements

- Safety margins

- Calibration intervals

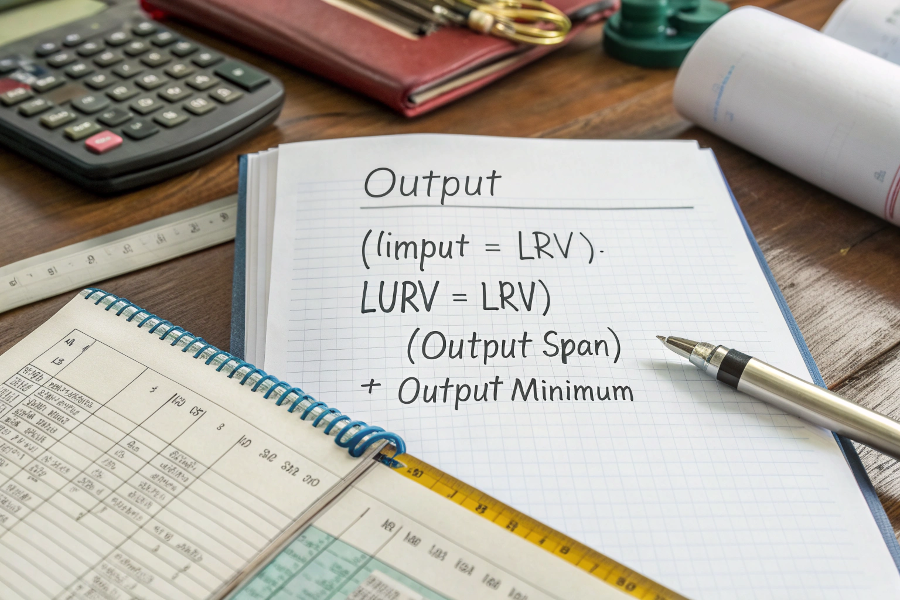

How To Calculate Pressure Transmitter?

Engineers often need guidance on proper transmitter calculations.

Calculate pressure transmitter settings using the formula: Output = ((Input – LRV) / (URV – LRV)) × (Output span) + Output minimum.

Pressure Transmitter Calculation

Based on our field experience:

Calculation Process

Key Parameters

Parameter Definition Usage LRV Lower Range Value Zero point URV Upper Range Value Span end Input Process pressure Variable Output Signal (4-20mA) Result Setup Requirements

- Zero calibration

- Span adjustment

- Linear scaling

- Signal damping

Implementation Steps

Range Setting

- Process limits

- Safety margins

- Turndown ratio

- Resolution needs

Verification Process

- Loop check

- Range validation

- Zero verification

- Span confirmation

How To Calculate DP Type Flow Transmitter Range?

Setting correct flow ranges is crucial for accurate measurements.

Calculate flow range using Q = K√ΔP, where Q is flow rate, K is flow coefficient, and ΔP is differential pressure. Then determine URV and LRV based on maximum and minimum flows.

Flow Range Calculation

Flow Range Calculation

Drawing from our technical expertise:

Range Calculation Steps

Flow Parameters

Parameter Purpose Calculation Maximum Flow URV setting Design max Minimum Flow LRV setting Design min Turndown Range ability Max/Min ratio K Factor Flow coefficient Calibration Critical Factors

- Pipe size

- Fluid properties

- Operating conditions

- Accuracy requirements

Range Optimization

Design Considerations

- Process variations

- Control requirements

- Measurement stability

- Energy efficiency

Operation Factors

- Normal flow

- Maximum flow

- Minimum flow

- Turndown needs

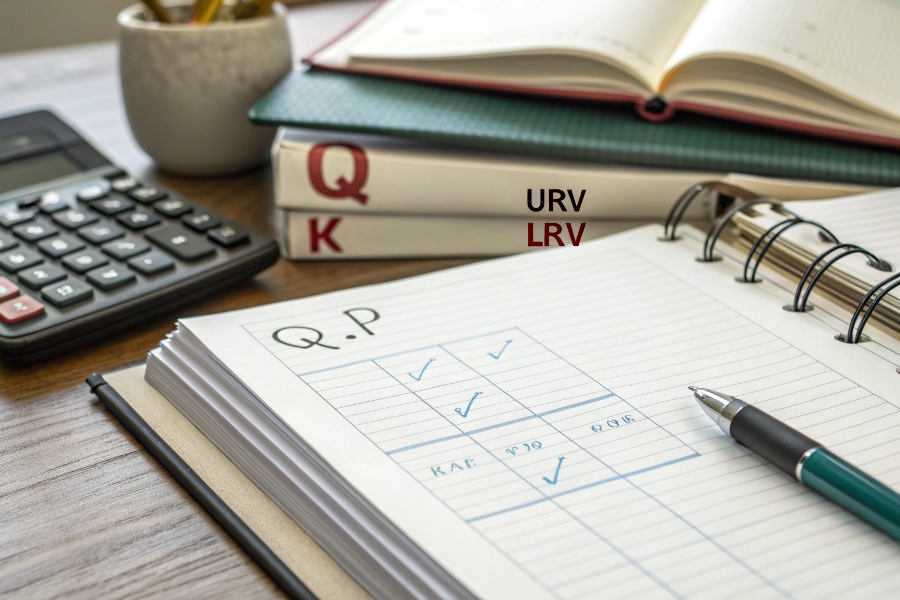

How To Calculate LRV And URV For Flow Transmitter?

Setting proper LRV and URV values is essential for accurate flow measurement.

Calculate LRV as the minimum required flow rate and URV as the maximum expected flow rate, considering the square root relationship between flow and differential pressure.

LRV and URV Calculation

Based on our setup experience:

LRV/URV Determination

Setting Parameters

Value Definition Consideration LRV Zero flow point Minimum flow URV Maximum flow Process max Span URV – LRV Range width Turndown URV/LRV ratio Rangeability Application Factors

- Process requirements

- Control needs

- Safety margins

- Equipment limits

Implementation Guidelines

Calculation Steps

- Process analysis

- Range determination

- Span calculation

- Signal scaling

Verification Process

- Range check

- Signal test

- Response verification

- Documentation

Conclusion

Accurate differential pressure calculations and proper range settings are crucial for reliable flow measurement, requiring careful consideration of process conditions and measurement requirements.