Tank operators often face challenges with unreliable level measurements, leading to inventory discrepancies and potential safety risks.

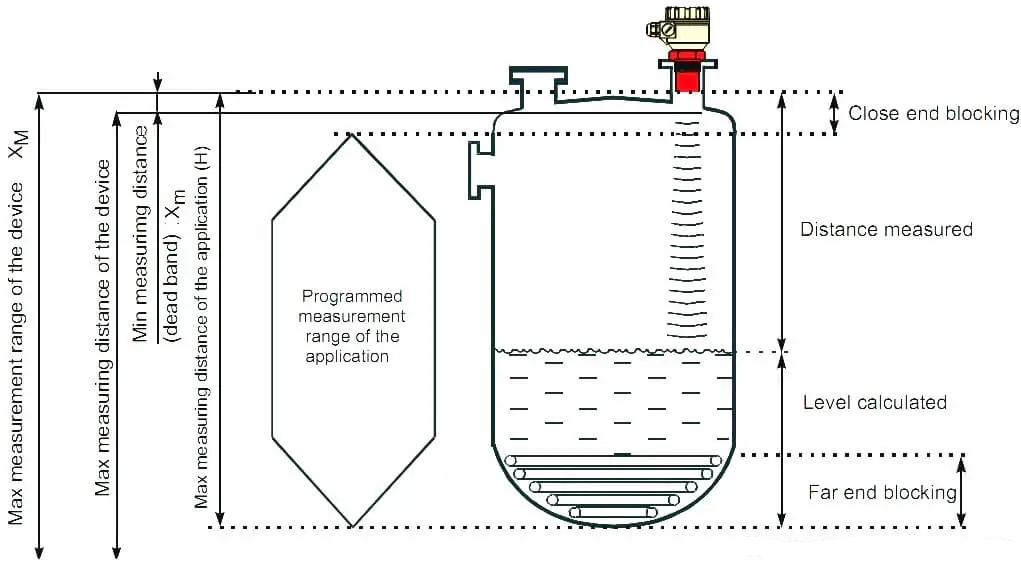

Ultrasonic level sensors are non-contact devices that measure tank contents by emitting sound waves and calculating distance based on echo time. They provide accurate measurements with typical accuracy of ±0.25%.

Ultrasonic Level Sensor Tank Installation

Let me share insights from my years of experience implementing tank level monitoring solutions.

What Type of Sensor Is Typically Used for Liquid Level Detection in Tanks?

Choosing the right sensor type is crucial for accurate measurements.

Ultrasonic sensors are the most common choice for liquid level detection due to their reliability, easy maintenance, and non-contact operation. They work well with various liquids and tank configurations.

%(percentage)sensor-types

Tank Level Sensor Types

Here’s what I’ve learned from numerous installations:

Available Sensor Technologies

Contact Sensors

Type Advantages Limitations Float Simple, low cost Mechanical wear Capacitive Good accuracy Regular cleaning Conductive Simple design Limited applications Non-Contact Sensors

Type Advantages Limitations Ultrasonic Easy maintenance Vapor sensitivity Radar High accuracy Higher cost Laser Precise Environmental sensitivity

Selection Criteria

- Tank dimensions

- Liquid properties

- Environmental conditions

- Budget considerations

- Accuracy requirements

These factors guide the selection of optimal sensor technology.

What Is the Ultrasonic Sensor for Water Tank Level?

Water tank monitoring requires reliable measurement solutions.

Ultrasonic sensors for water tanks are specialized devices designed to measure water levels accurately. They typically operate at frequencies between 20-200 kHz and provide continuous level monitoring.

Water Tank Level Measurement

Based on my implementation experience:

Key Features

Technical Specifications

- Measurement range: 0.3-8m typical

- Accuracy: ±0.25%

- Output options: 4-20mA, digital

- Power supply: 24VDC typical

Application Benefits

- Non-contact measurement

- Easy installation

- Low maintenance

- Cost-effective operation

Implementation Considerations

Installation Requirements

- Proper mounting

- Cable protection

- Signal routing

- Power connection

Configuration Steps

- Tank parameters

- Calibration settings

- Alarm points

- Output scaling

These aspects ensure optimal sensor performance.

What Should I Avoid with Ultrasonic Level Sensors?

Understanding limitations prevents measurement errors.

Avoid installing sensors in locations with excessive vapor, foam, or turbulence. Keep sensors away from tank walls and ensure proper alignment and ventilation.

Ultrasonic Sensor Installation Guidelines

From my troubleshooting experience:

Common Installation Mistakes

Physical Placement

- Too close to walls

- Improper alignment

- Insufficient clearance

- Unstable mounting

Environmental Factors

- High temperature exposure

- Excessive vapor presence

- Direct sunlight

- Heavy dust/particles

Best Practices

- Regular maintenance

- Signal monitoring

- Temperature compensation

- Proper ventilation

- Cable protection

Following these guidelines maximizes measurement reliability.

What Is a Tank Level Sensor?

Understanding sensor basics helps in selection and implementation.

A tank level sensor is a device that measures the amount of liquid or solid material in a tank. It converts level measurements into electronic signals for monitoring and control purposes.

Tank Level Sensor Basic Principles

Drawing from my field experience:

Sensor Fundamentals

Operating Principles Method Description Application Direct Physical contact Simple tanks Indirect Non-contact measurement Complex systems Calculated Pressure-based Large tanks Output Types

- Analog signals

- Digital communication

- Wireless transmission

- Local display

Application Areas

Industry Sectors

- Water treatment

- Chemical processing

- Food and beverage

- Oil and gas

- Manufacturing

Monitoring Requirements

- Continuous level

- Point level

- Interface detection

- Volume calculation

Understanding these aspects helps in proper sensor selection.

Conclusion

Ultrasonic level sensors provide reliable tank monitoring when properly selected and installed. Understanding their capabilities, limitations, and best practices ensures successful implementation across various applications.