After spending $23,000 to replace a seized turbine meter in a chemical plant, I learned the hard way that not all flow technologies suit every application. The right choice can slash maintenance costs by 60% while improving accuracy.

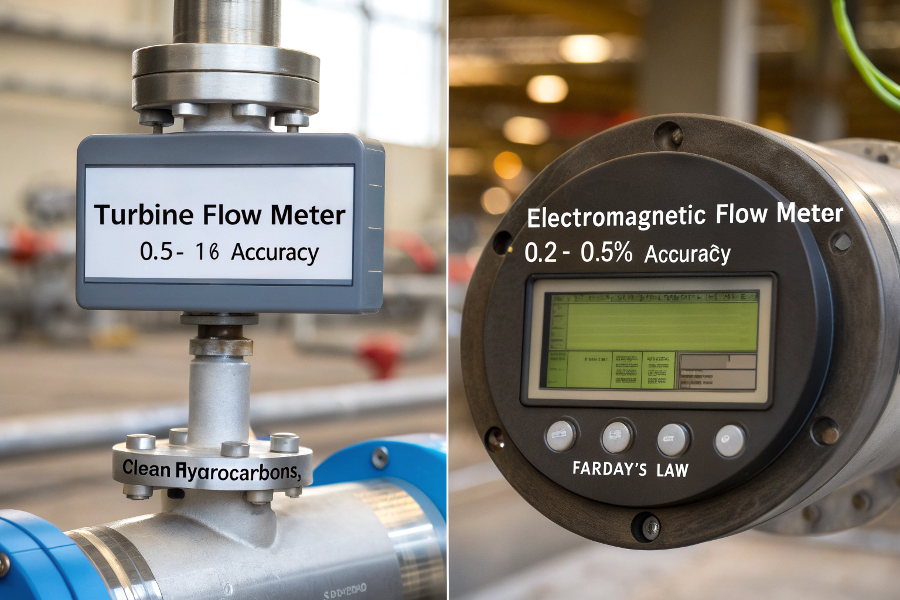

Key difference: Turbine meters (mechanical, 0.5-1% accuracy) use spinning blades disrupted by viscosity/solids, while electromagnetic meters (no moving parts, 0.2-0.5% accuracy) measure conductive liquids via Faraday’s Law. Electromagnetic handles sewage/slurries better; turbines excel in clean hydrocarbons.

Flow Meter Comparison

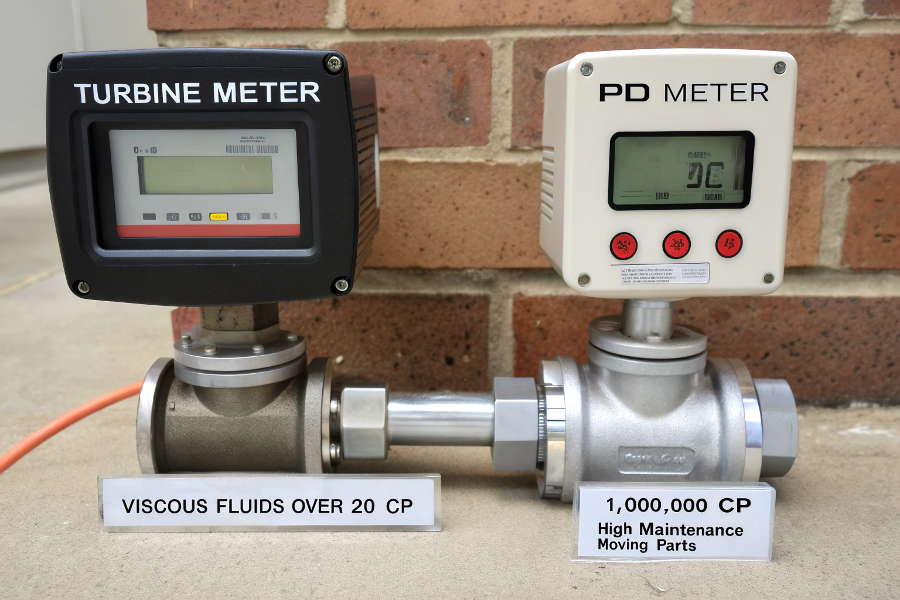

How Do Turbine and Positive Displacement (PD) Flow Meters Differ?

Seeing a PD meter’s gears jammed with paper pulp after just 72 hours convinced me to reevaluate our entire metering system at the paper mill.

Critical distinctions:

- Turbine Meters (dynamic measurement):

✔ Higher flow capacity

✔ Lower pressure drop

✖ Fails with viscous fluids (>20 cP) - PD Meters (volumetric counting):

✔ Handles viscosity up to 1,000,000 cP

✔ No straight-run requirements

✖ High maintenance moving parts

Mechanical Meter Types

5 Application-Specific Considerations

| Application | Better Choice | Why |

|---|---|---|

| Diesel fuel loading | Turbine | 0.25% accuracy at high flow |

| Molasses transfer | PD | Handles 10,000 cP viscosity |

| Lube oil blending | PD | Measures small batches precisely |

| Pipeline crude oil | Turbine | Lower ∆P over long distances |

| Chemical dosing | PD | ±0.1% accuracy at low flow |

Client Example: A Shell lubricants plant reduced downtime 80% by switching from turbine to PD meters for additive blending, despite 3× higher upfront cost.

Ultrasonic vs Turbine Flow Meters: When to Use Which?

The revelation came when our offshore platform’s turbine meters undercounted by 18% due to entrained gas – a $700,000 revenue loss over 5 years.

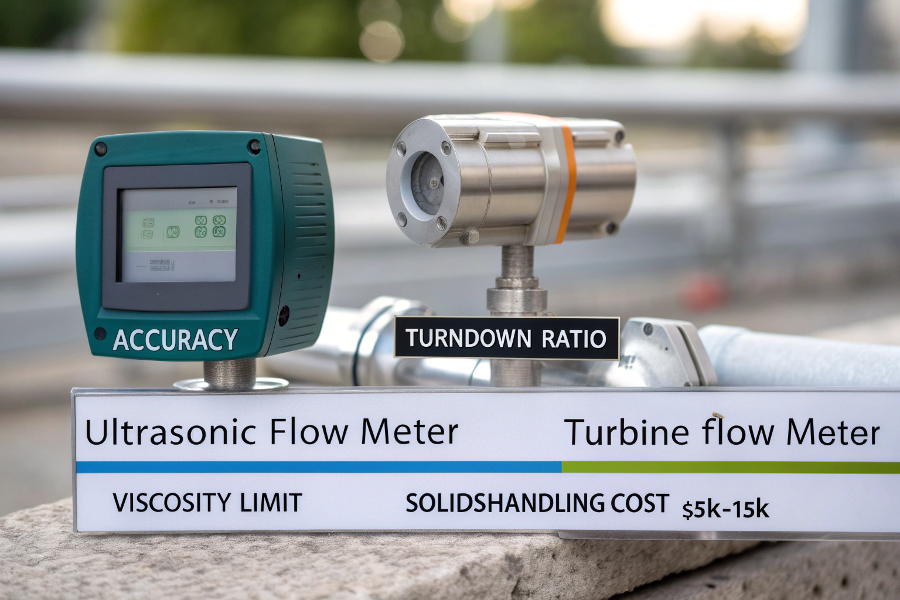

Technical showdown:

| Parameter | Ultrasonic | Turbine |

|---|---|---|

| Accuracy | ±0.5-1% | ±0.25-0.5% |

| Turndown | 100:1 | 10:1 |

| Viscosity Limit | Unlimited | <20 cP |

| Solids Handling | Excellent | Poor |

| Installation Cost | $5k-15k | $3k-8k |

Non-invasive Comparison

5 Decision Factors

Fluid Type

- Ultrasonic: Crude oil with sand

- Turbine: Clean LNG

Flow Range

- Ultrasonic: Highly variable flows

- Turbine: Steady high flows

Maintenance

- Ultrasonic: 10+ year lifespan

- Turbine: Annual bearing changes

Upfront Cost

- Turbine wins under $5k budgets

Accuracy Needs

- Custody transfer? Pay extra for Coriolis

Case Study: Chevron saved $2.1M/year by using ultrasonic instead of turbine meters in 32 multiphase flowlines.

Which Flow Meter Type Delivers Maximum Accuracy?

Discovering 0.03% error in our custody transfer meters meant recovering $280,000 in lost revenue annually – proving accuracy matters.

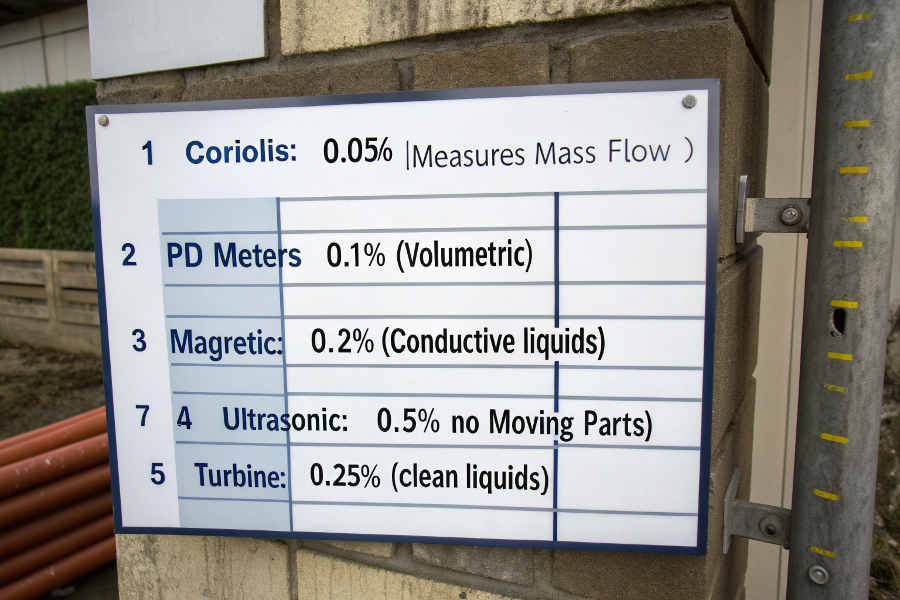

Accuracy hierarchy (typical):

1️⃣ Coriolis: ±0.05% (measures mass flow)

2️⃣ PD meters: ±0.1% (volumetric)

3️⃣ Magnetic: ±0.2% (conductive liquids)

4️⃣ Ultrasonic: ±0.5% (no moving parts)

5️⃣ Turbine: ±0.25% (clean liquids only)

flow meter accuracy

Total Measurement Uncertainty Components

| Error Source | Turbine | Magnetic | Coriolis |

|---|---|---|---|

| Calibration | ±0.15% | ±0.1% | ±0.02% |

| Installation | ±0.3% | ±0.05% | ±0.01% |

| Fluid Changes | ±0.5% | ±0.1% | ±0.05% |

| Long-term Drift | ±0.2%/yr | ±0.05%/yr | ±0.01%/yr |

Pro Tip: ISO 5167 requires considering all uncertainty components – ExxonMobil’s spreadsheet tracks 14 variables for custody transfer.

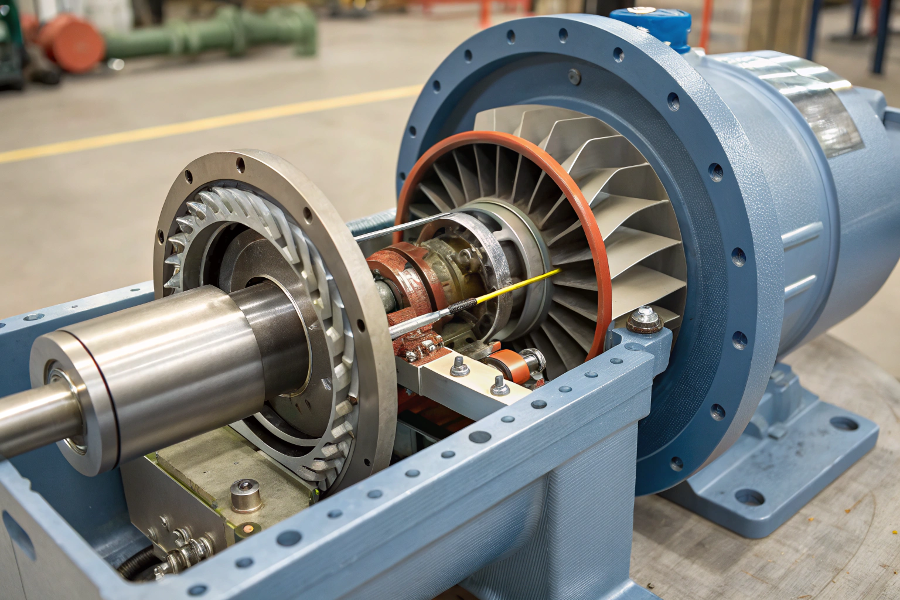

What Exactly is a Turbine Flow Meter?

That moment when I took apart a 15-year-old turbine meter and found the bearings had worn 0.3mm, causing 8% under-registration of gasoline flows.

Turbine meter anatomy:

- Rotor: Balanced blades (typically 6-10)

- Bearings: Hardest-wearing component

- Pickup: Magnetic or RF sensor

- Straightener: Vanes remove swirl

Key specs:

- Size: ½" to 24"

- Flow Range: 0.3-10 m/s

- Pressure: Up to 6,000 psi

- Temperature: -200°C to 350°C

Internal Components

Performance Curve Characteristics

| Flow Rate | % Accuracy | Behavior |

|---|---|---|

| <10% max | Unusable | Stall |

| 10-30% | ±1-2% | Nonlinear |

| 30-100% | ±0.25-0.5% | Linear |

| >100% | Damage | Overspeed |

Maintenance Reality: Every 2-5 years needs new bearings ($800-$2,000) and rotor inspection. Saudi Aramco’s 2,000 turbine meters average 3,100 operating hours between failures.

Conclusion

Selecting between turbine and electromagnetic flow meters requires evaluating fluid properties, accuracy needs, and lifecycle costs. For dirty/conductive fluids, electromagnetic wins; clean hydrocarbons favor turbines. Always conduct a 10-year TCO analysis before deciding.

Need help choosing? Download our flow meter selector matrix covering 28 selection criteria across all major technologies.