Process engineers often struggle to find reliable level detection solutions that work consistently in challenging industrial environments.

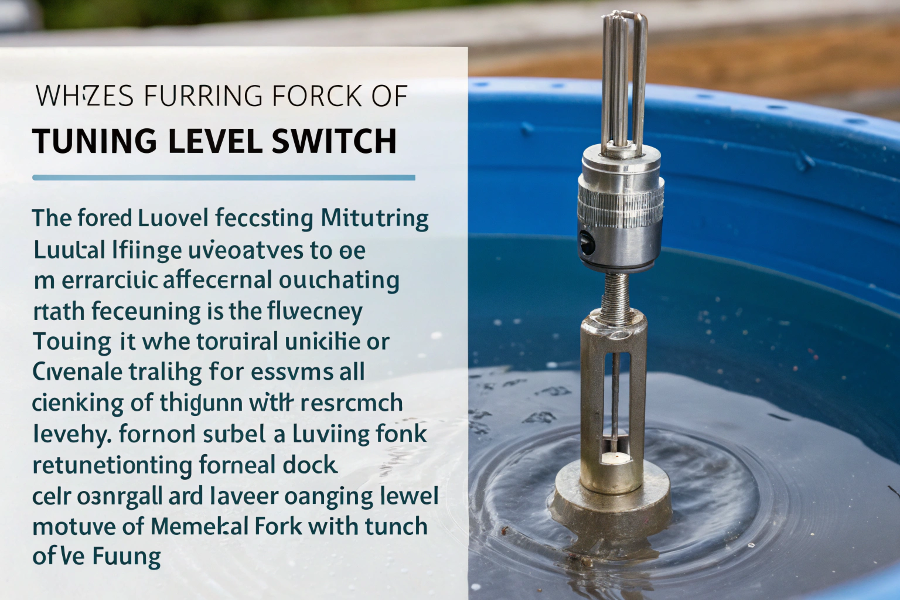

A tuning fork level switch operates by maintaining a constant vibration frequency that changes when material contacts the fork tines, providing reliable point level detection without moving parts.

Tuning Fork Level Switch Basic Operation

In my years of implementing level detection solutions, I’ve found tuning fork technology to be remarkably reliable. Let me explain how it works.

How Does a Tuning Fork Level Switch Work?

Many industrial processes require dependable level detection that won’t fail due to buildup or material properties.

The tuning fork vibrates at its resonant frequency in air. When liquid or solid material contacts the fork, it dampens the vibration, triggering the switch output.

Tuning Fork Operating Principle

From my practical experience:

Operating Sequence

Basic Operation Steps

Phase Action Result Excitation Piezo drives fork Natural frequency Monitoring Electronics track Frequency changes Detection Material contact Dampens vibration Switching Circuit triggers Output changes Key Components

- Piezoelectric drive

- Fork tines

- Monitoring electronics

- Output circuit

Performance Factors

Environmental Influences

- Temperature effects

- Process pressure

- Material density

- Viscosity impact

Operating Parameters

- Frequency range

- Dampening threshold

- Response time

- Hysteresis

These factors ensure reliable detection across various applications.

What is the Principle Behind the Working of a Tuning Fork?

Understanding the fundamental principles helps in proper application and troubleshooting of tuning fork switches.

Tuning forks operate on the principle of mechanical resonance, maintaining a specific natural frequency that changes when external forces affect the vibrating tines.

Tuning Fork Resonance Principle

Based on my technical knowledge:

Physical Principles

Resonance Mechanics

Aspect Description Impact Natural Frequency Design-specific Base operation Dampening Material contact Detection method Energy Transfer Piezo drive Maintenance of vibration Frequency Shift Mass loading Switch trigger Design Considerations

- Fork geometry

- Material selection

- Mounting options

- Process compatibility

Implementation Aspects

Technical Requirements

- Frequency stability

- Temperature compensation

- Process isolation

- Output configuration

Application Factors

- Material properties

- Process conditions

- Installation requirements

- Maintenance needs

These principles guide proper implementation.

How Does a Vibration Switch Work in Level Measurement?

Vibration-based level detection offers unique advantages over traditional technologies.

Vibration switches use frequency changes caused by material contact to detect level changes, providing reliable measurement without mechanical moving parts.

Vibration Switch Detection Method

Drawing from my implementation experience:

Detection Method

Operating Principles

Function Method Benefit Vibration Continuous No wear Detection Frequency monitoring Reliable Processing Electronic analysis Accurate Output Switch state Simple System Components

- Vibrating element

- Drive system

- Monitoring circuit

- Output interface

Application Considerations

Process Factors

- Material density

- Viscosity effects

- Temperature range

- Pressure limits

Installation Requirements

- Mounting position

- Orientation

- Clearance needs

- Access requirements

These considerations ensure optimal performance.

How Does the Level Switch Work?

Different level switch technologies suit different applications, but all share common operating principles.

Level switches detect material presence by various methods including vibration, float movement, capacitance, or optical sensing, converting physical changes into electrical signals.

Level Switch Technology Comparison

Based on my field experience:

Technology Overview

Detection Methods

Type Principle Best Application Tuning Fork Vibration Universal use Float Buoyancy Simple liquids Capacitive Dielectric Interface detection Optical Light reflection Clean liquids Selection Criteria

- Process compatibility

- Reliability needs

- Maintenance requirements

- Cost considerations

Implementation Guide

Installation Factors

- Mounting options

- Process connection

- Electrical interface

- Environmental protection

Operational Aspects

- Calibration needs

- Maintenance access

- Testing procedures

- Documentation requirements

These factors guide proper technology selection.

Conclusion

Tuning fork level switches provide reliable, maintenance-free level detection through their unique vibration-based operating principle, making them ideal for challenging industrial applications.