Did your mag meter suddenly stop giving reliable readings? Before you reset, know this: factory resets erase ALL custom settings.

To safely reset an electromagnetic flow meter: Power off, hold both arrow buttons while powering on, wait for "FAC" display (3-5 sec), press Enter to confirm, then re-enter basic parameters (pipe size, units, K-factor). Avoid full resets unless absolutely necessary – calibration settings will be lost.

Button Sequence for Factory Reset

Here’s how to distinguish between needed recalibration vs. risky full reset.

How to Reset Electromagnetic Flow Meter?

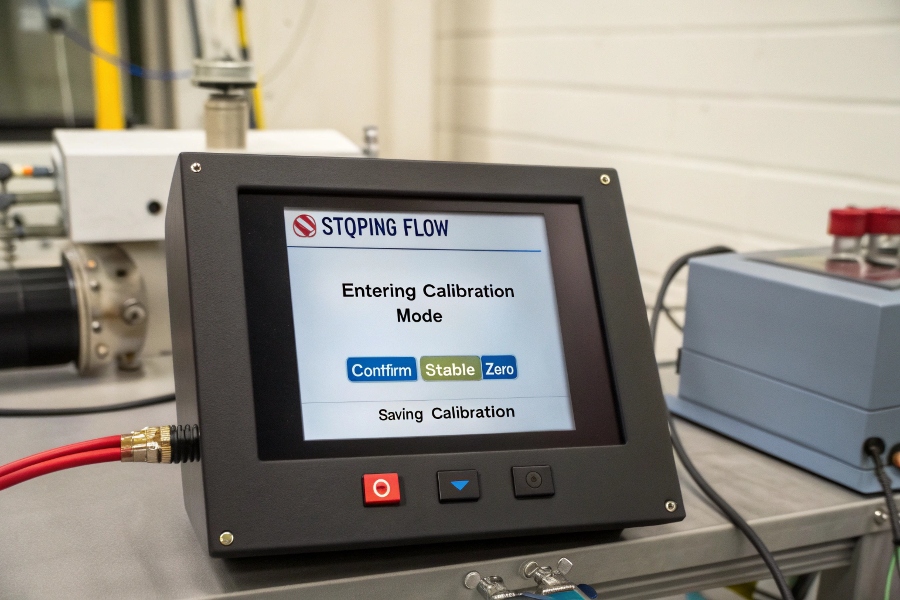

Most "resets" are actually just zero adjustments.

For 90% of issues: Try zero calibration first (stop flow, enter calibration mode, confirm stable zero, save). Full factory reset should ONLY be used for configuration corruption or post-repairs. Document all settings before resetting – you’ll need to reinput pipe diameter, liner material, and electrode type.

Zero Adjustment Menu

Critical pre-reset checklist:

Settings You MUST Record Before Resetting

| Parameter | Location in Menu | Typical Value | Importance |

|---|---|---|---|

| Pipe diameter | Basic Configuration | 100mm | Affects all flow calc |

| Liner material | Meter Properties | PTFE | Chemical compatibility |

| Electrode type | Sensor Config | 316L Stainless | Measurement accuracy |

| K-factor | Calibration | 1.023 (unique) | Custom calibration |

| Output scaling | I/O Configuration | 4-20mA = 0-100m³/h | Control system match |

How to Reset Digital Flow Meter?

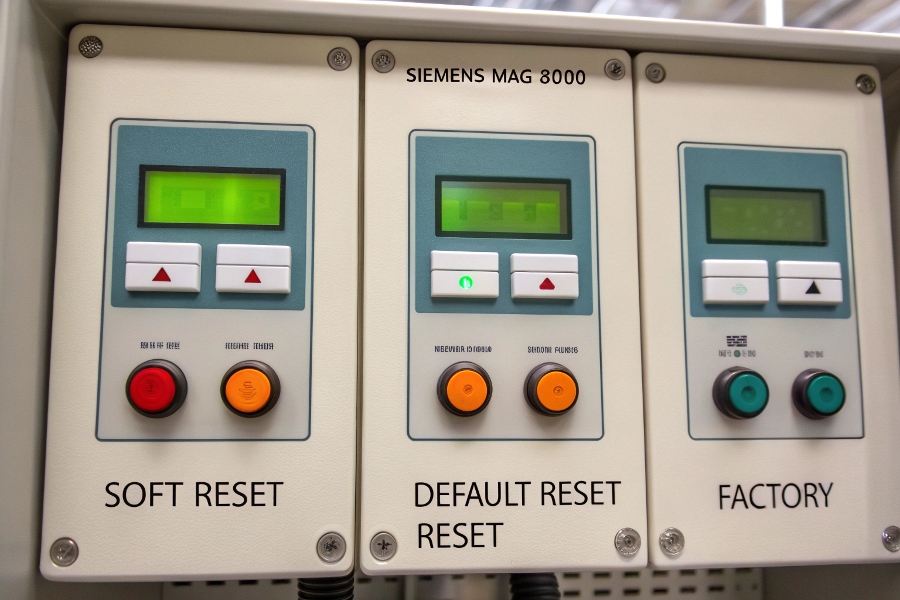

Digital doesn’t mean "self-repairing" – understand your reset options.

Three reset levels: 1) Soft reset (power cycle, keeps settings), 2) Default reset (backs to shipped config), 3) Factory reset (wipes all). Use 10-second power button hold for soft reset on most digital meters. For Siemens MAG 6000, press ▲▼◄► simultaneously for 5 seconds.

Reset Type Comparison

Manufacturer-specific procedures:

Common Digital Meter Reset Sequences

| Brand/Model | Soft Reset | Factory Reset |

|---|---|---|

| Krohne Waterflux | Power cycle | Hold ENTER+ESC 8 sec |

| Endress Promag 50 | ▲+▼ during startup | Service tool required |

| Yokogawa ADMAG TI | Mode+Power 3 sec | Password-protected menu |

| ABB FMT500 | Front panel combo | Jumper switch inside |

How to Calibrate an Electromagnetic Flow Meter?

Calibration and reset serve different purposes – know when to use each.

For calibration: 1) Zero adjust (no flow condition), 2) Span adjust (known reference flow), 3) Linearization (mid-range checks). Unlike resetting, calibration preserves configuration while improving accuracy. Use calibration first – it fixes 80% of "need reset" cases.

Accuracy Recovery Methods

Step-by-step calibration guide:

Field Calibration Protocol

| Step | Action | Tolerance | Tools Needed |

|---|---|---|---|

| Zero Verification | Isolate meter, verify zero | ±0.5% of span | Process multimeter |

| Flow Test 1 | 25% flow rate comparison | ±1% of reading | Ultrasonic clamp-on |

| Flow Test 2 | 70% flow rate verification | ±0.7% of reading | Tank scale/clock |

| Final Adjustment | Modify K-factor if needed | Max ±2% change | Calibration report |

How Do I Reset My Airflow Meter?

Gas meters need special considerations – don’t treat like liquid meters.

Key differences: 1) Always perform zero in actual process gas (not air), 2) Temperature compensation is critical, 3) Most require proprietary software for full reset. For thermal meters, resetting also clears the gas property library – potentially dangerous if wrong gas is selected.

Thermal Meter Service Mode

Gas-specific precautions:

Air/Gas Meter Reset Warnings

| Meter Type | Reset Risk | Mandatory Checks Post-Reset |

|---|---|---|

| Thermal Mass | Gas database cleared | Reinstall gas parameters |

| Differential Press | Flow calculations lost | Re-enter STD conditions |

| Vortex | K-factor & density wiped | Verify fluid states |

| Ultrasonic | Profile correlation deleted | Re-map flow profile |

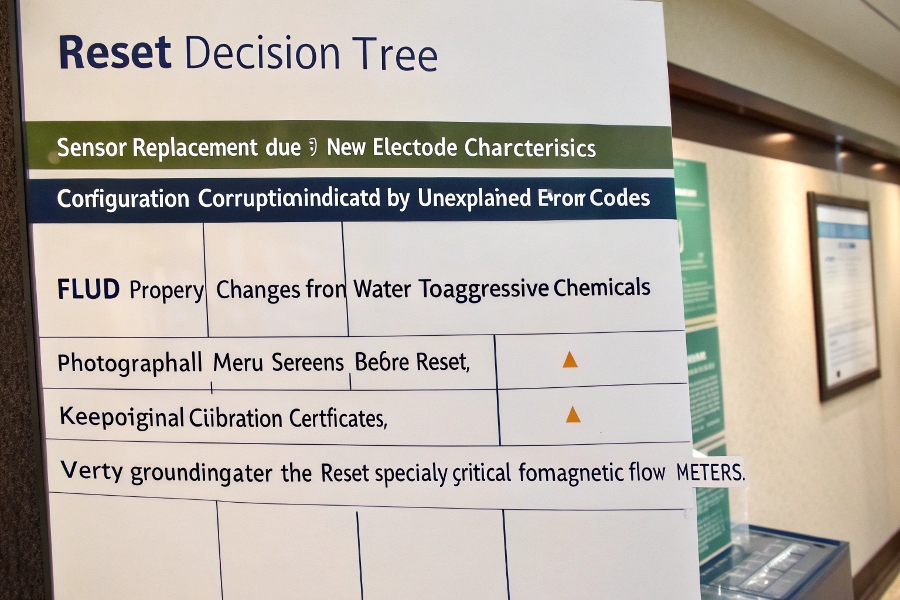

When Resetting Is Truly Necessary

Despite warnings, three legitimate cases demand full reset:

1) After sensor replacement (new electrode characteristics)

2) Configuration corruption (unexplained error codes)

3) Fluid property changes (switch from water to aggressive chemical)

Always:

- Photograph all menu screens pre-reset

- Keep original calibration certificates

- Verify grounding post-reset (critical for mag meters)

Reset Justification Flowchart

Conclusion

Resetting an electromagnetic flow meter should remain a last resort – prioritize recalibration and diagnostics first. When resetting becomes unavoidable, meticulous documentation of original parameters ensures faster recovery.