Choosing the wrong flow meter can lead to measurement inaccuracies, maintenance headaches, and wasted investment.

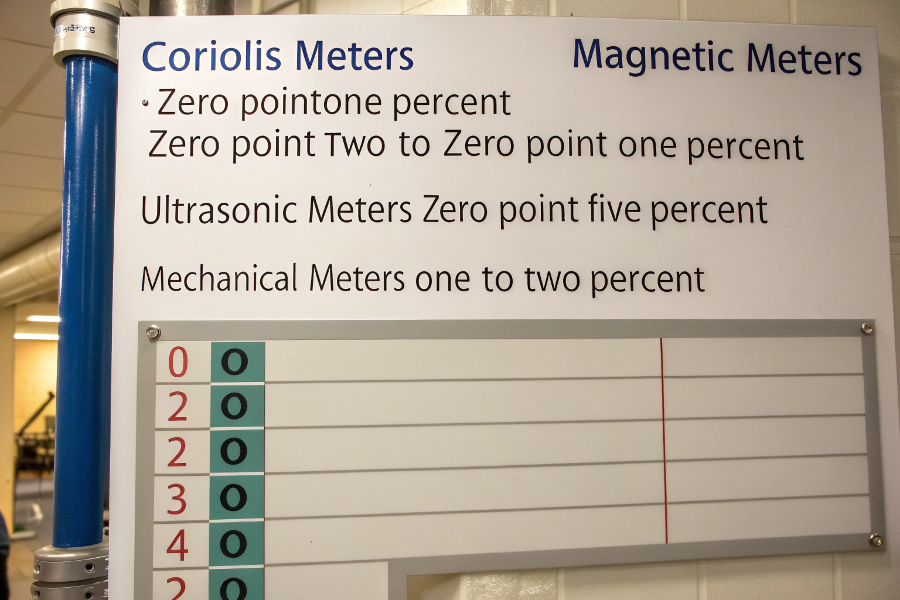

Flow meter technologies vary in accuracy from 0.1% to 5%, with Coriolis meters offering the highest accuracy (0.1%), followed by magnetic (0.2-0.5%), ultrasonic (0.5-1%), and mechanical meters (1-2%).

Flow Meter Technology Comparison Chart

I’ve worked with various flow meter technologies, and here’s my comprehensive analysis.

What is the Most Accurate Type of Flow Meter?

Many industrial processes suffer from measurement errors due to selecting less accurate flow meters for critical applications.

Coriolis flow meters provide the highest accuracy at ±0.1% of rate, directly measuring mass flow while being largely immune to fluid property changes and flow profile effects.

Flow Meter Accuracy Comparison

Based on my field experience:

Accuracy Comparison

Technology Rankings

Technology Accuracy Repeatability Coriolis ±0.1% ±0.05% Magnetic ±0.2% ±0.1% Ultrasonic ±0.5% ±0.15% Vortex ±0.7% ±0.2% Influencing Factors

- Installation conditions

- Fluid properties

- Flow range

- Environmental factors

Application Considerations

Selection Criteria

- Process requirements

- Cost constraints

- Maintenance needs

- Installation limits

Performance Optimization

- Calibration frequency

- Installation quality

- Regular maintenance

- Environmental protection

Understanding accuracy requirements ensures proper selection.

What are the Different Types of Flowmeters?

Misunderstanding flow meter types and their applications can result in poor measurement performance and unnecessary costs.

Common flow meter types include differential pressure, electromagnetic, ultrasonic, Coriolis, vortex, and mechanical meters, each suited for specific applications and conditions.

From my experience with various technologies:

Technology Overview

Operating Principles

Type Measurement Principle Best Application Magnetic Faraday’s Law Conductive Liquids Ultrasonic Sound Wave Transit Clean Liquids/Gas Coriolis Mass Flow Direct High Accuracy Needs Vortex Vortex Shedding Steam/Gas/Liquid Application Factors

- Fluid type

- Flow conditions

- Process requirements

- Installation constraints

Selection Guidelines

Key Considerations

- Accuracy needs

- Cost limitations

- Maintenance capability

- Environmental conditions

Installation Requirements

- Space availability

- Straight run needs

- Power availability

- Communication options

Understanding technology options enables proper selection.

What are the Disadvantages of Ultrasonic Flow Meter?

Overlooking ultrasonic flow meter limitations can lead to unexpected measurement problems and system failures.

Ultrasonic flow meters face challenges with aerated fluids, high-solid content, and signal distortion, requiring specific installation conditions and fluid clarity for optimal performance.

Based on my troubleshooting experience:

Common Challenges

Limitation Categories

Challenge Impact Solution Air Bubbles Signal Loss De-aeration Solids Content Accuracy Drop Filtration Signal Path Installation Issues Proper Mounting Temperature Changes Drift Compensation Installation Issues

- Straight run requirements

- Mounting location

- Signal interference

- Environmental effects

Mitigation Strategies

Design Considerations

- Path configuration

- Transducer selection

- Installation planning

- Maintenance access

Operating Requirements

- Regular cleaning

- Signal monitoring

- Calibration checks

- Environmental protection

Understanding limitations enables proper application.

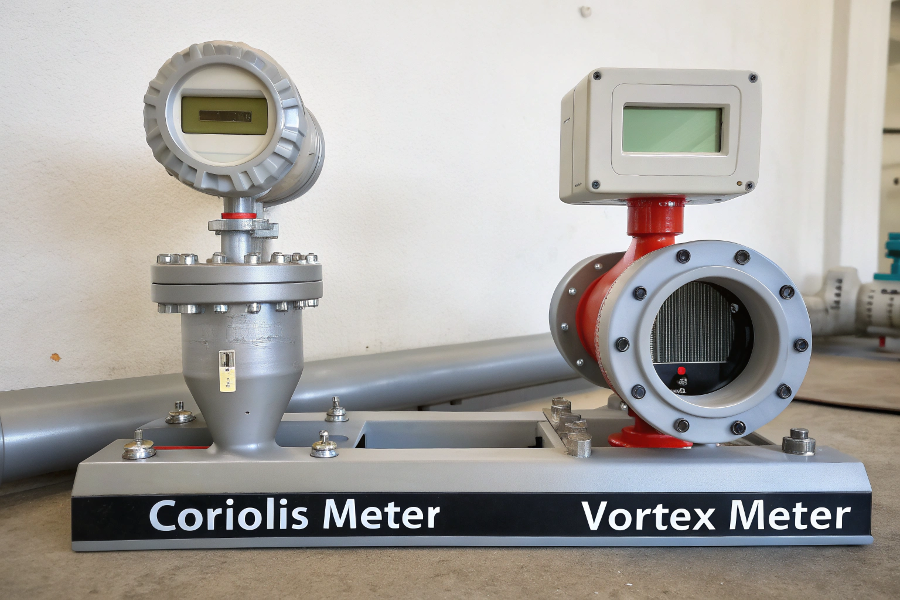

What is the Difference Between Coriolis and Vortex Flow Meter?

Confusion between Coriolis and vortex technologies can result in improper meter selection and application.

Coriolis meters measure mass flow directly using tube vibration principles, while vortex meters measure volumetric flow by counting vortices created by flow obstacles.

Coriolis vs Vortex Flow Meter Comparison

From my experience with both technologies:

Technical Differences

Key Characteristics

Feature Coriolis Vortex Accuracy ±0.1% ±0.7% Mass Flow Direct Inferred Pressure Drop Higher Medium Cost Higher Lower Application Factors

- Flow ranges

- Fluid properties

- Process conditions

- Installation requirements

Selection Guidelines

Process Considerations

- Accuracy needs

- Budget constraints

- Maintenance capability

- Space availability

Installation Requirements

- Mounting options

- Support needs

- Straight runs

- Power requirements

Understanding differences ensures proper selection.

Conclusion

Each flow meter technology has unique strengths and limitations, making proper selection critical for achieving optimal measurement performance in specific applications.