Last month, a manufacturing plant was shocked by their energy bills. Without proper energy monitoring, they had no idea they were wasting 40% of their heating costs.

Clamp on ultrasonic flow meters measure energy by combining flow rate measurements with temperature data. They calculate thermal energy by measuring the temperature difference between supply and return lines.

I’ve spent years helping facilities optimize their energy monitoring. Let me explain how these systems work and why they’re so effective.

How Does Ultrasonic Technology Convert Flow to Energy Measurement?

During a recent installation, a client was amazed to see real-time energy calculations from simple external sensors. The technology behind this is fascinating.

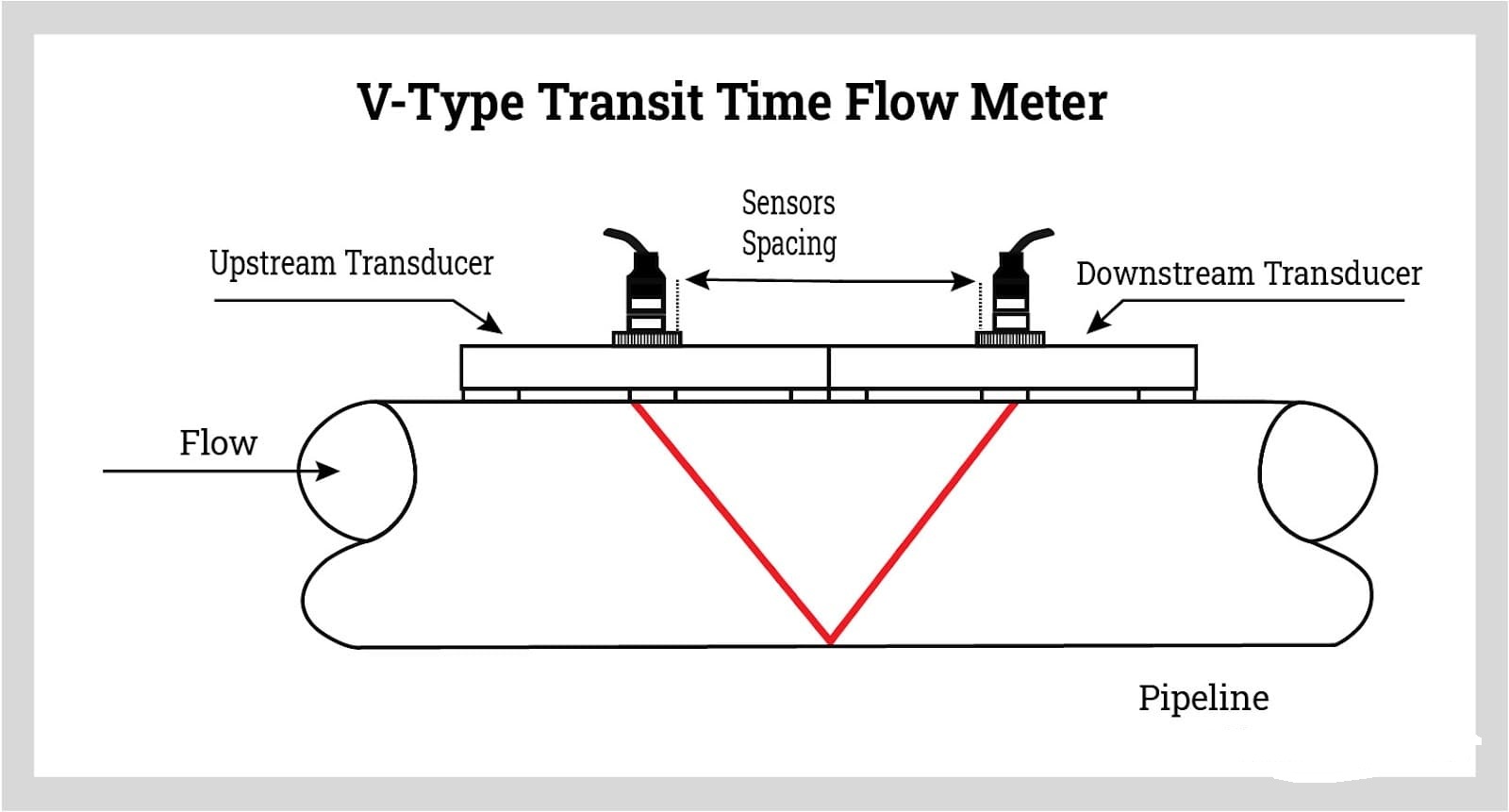

Ultrasonic meters measure transit time differences to determine flow rate, then multiply it by specific heat capacity and temperature difference to calculate energy transfer.

Ultrasonic Measurement Principle

Understanding the Energy Calculation Process

Measurement Components

Parameter Method Purpose Accuracy Impact Flow Rate Transit Time Volume measurement ±1% Temperature RTD Sensors ΔT measurement ±0.1°C Specific Heat Fluid Properties Energy content Based on fluid Density Temperature Compensation Mass flow Dynamic update Calculation Steps

- Flow velocity measurement

- Volume flow calculation

- Temperature difference monitoring

- Energy rate computation

- Consumption totalization

How Is Energy Monitored Across Different Applications?

I recently helped a hospital reduce their chilled water energy costs by 25% through precise monitoring.

Energy monitoring varies by application – HVAC systems focus on BTU calculations, while industrial processes might measure steam energy or cooling loads.

Application-Specific Monitoring

Energy Monitoring1 by Sector

Application Energy Type Key Parameters Benefits HVAC2 Thermal ΔT, flow rate Efficiency Industrial Process heat Steam flow, pressure Cost control District heating Distribution Network balance Billing Cooling systems Refrigeration Cooling load Optimization

Why Are Temperature Sensors Critical for Energy Measurement?

One facility saved $100,000 annually after upgrading to high-precision temperature sensors in their energy monitoring system.

Temperature sensors provide the critical ΔT value needed for energy calculations. Precise temperature measurement can mean the difference between profit and loss.

Temperature Measurement Integration

Temperature Sensing Requirements

Component Function Accuracy Need Integration RTD Sensors ΔT measurement ±0.1°C Direct mount Transmitters Signal conversion High stability 4-20mA output Calibration Accuracy ensure Regular checks Traceability Compensation Error reduction Dynamic Software based

What Makes Clamp-On Meters Ideal for Energy Measurement?

A chemical plant avoided a week-long shutdown by using clamp-on meters for their energy audit. The non-invasive installation made all the difference.

Clamp-on meters offer non-invasive installation, zero pressure drop, and maintenance-free operation. They can be installed without process interruption.

Benefits Analysis

Installation and Operation Advantages

Feature Benefit Cost Impact ROI Factor Non-invasive No pipe cutting Labor savings Immediate Zero pressure drop Energy savings Efficiency gain Continuous No maintenance Reduced costs Operating expense Long-term Portable option Flexibility Multiple use High value

What Technical Challenges Must Be Addressed?

Last week, I solved a tricky installation where pipe coating was affecting measurement accuracy. Technical challenges require specific solutions.

Key challenges include proper sensor positioning, acoustic coupling, and signal processing in difficult conditions. Solutions involve advanced algorithms and installation techniques.

Challenge Resolution Strategies

Common Issues and Solutions

Challenge Impact Solution Result Signal noise Accuracy loss Advanced DSP Clean data Pipe condition Coupling issues Surface prep Better signal Flow profile Reading errors Path optimization Higher accuracy Environmental Interference Shielding Stability

Conclusion

Clamp-on ultrasonic flow meters offer a versatile, accurate solution for energy measurement across various applications, combining flow and temperature data for comprehensive energy monitoring.

Need help designing your energy monitoring system? Contact our experts for a customized solution.