Many engineers and facility managers worry about measurement accuracy when selecting flow meters for their applications.

Modern ultrasonic flow meters can achieve accuracy rates of ±0.5% to ±2% of reading, depending on the model, installation, and application conditions.

Ultrasonic Flow Meter Accuracy Comparison

Let me share my experience with ultrasonic flow meter accuracy and the factors that influence it.

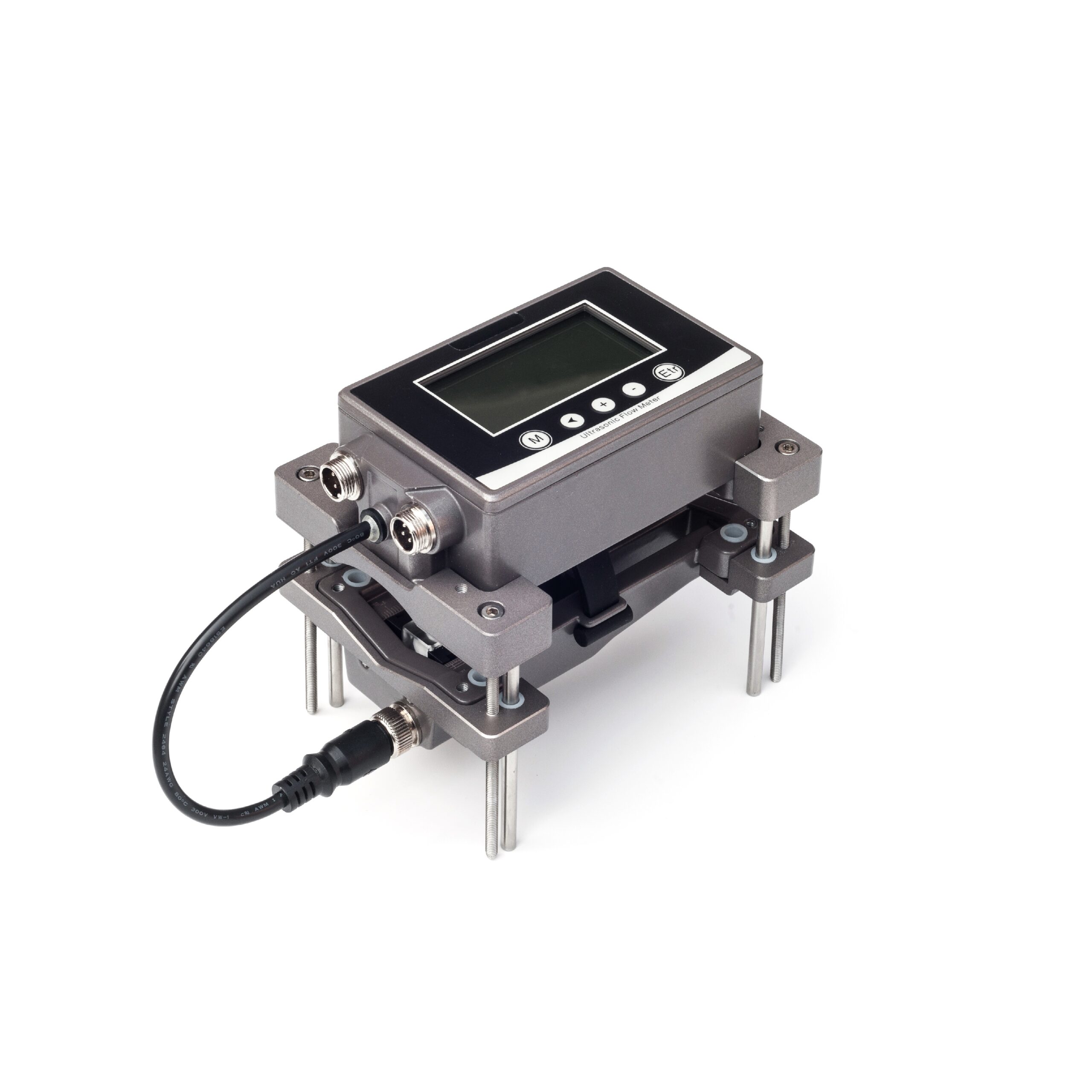

Are Ultrasonic Flow Meters Accurate?

Facility managers often question whether ultrasonic technology can provide reliable measurements for their critical processes.

Ultrasonic flow meters are highly accurate when properly installed and maintained, offering stable measurements across a wide flow range with minimal drift over time.

Factors Affecting Ultrasonic Flow Meter Accuracy

From my field experience:

Accuracy Factors

-

Key Parameters

Factor Impact Solution Best Practice Installation Signal quality Proper mounting Follow guidelines Flow profile Reading accuracy Straight runs Adequate spacing Fluid properties Signal strength Regular checks Fluid analysis Calibration Measurement drift Regular verification Scheduled maintenance -

Performance Optimization

- Signal strength monitoring

- Zero point verification

- Regular calibration

- Environmental protection

Application Considerations

-

Installation Requirements

- Pipe condition assessment

- Mounting location selection

- Environmental factors

- Power supply stability

-

Maintenance Protocol

- Regular inspections

- Performance monitoring

- Calibration schedule

- Documentation

What Is The Most Accurate Flow Meter?

Finding the most accurate flow measurement solution can be challenging with so many options available.

Coriolis flow meters generally provide the highest accuracy (±0.1%), followed by ultrasonic meters, but the best choice depends on specific application requirements.

Flow Meter Technology Comparison

Based on my expertise:

Technology Comparison

-

Accuracy Rankings

Technology Typical Accuracy Best For Limitations Coriolis ±0.1% Mass flow High cost Ultrasonic ±0.5% Clean liquids Installation sensitive Magnetic ±0.2% Conductive fluids Limited applications Vortex ±1.0% Steam/gas Minimum flow required -

Selection Criteria

- Process requirements

- Budget constraints

- Installation conditions

- Maintenance capabilities

Application-Specific Factors

-

Industry Requirements

- Custody transfer

- Process control

- Billing applications

- Regulatory compliance

-

Cost Considerations

- Initial investment

- Installation expenses

- Maintenance costs

- Life cycle value

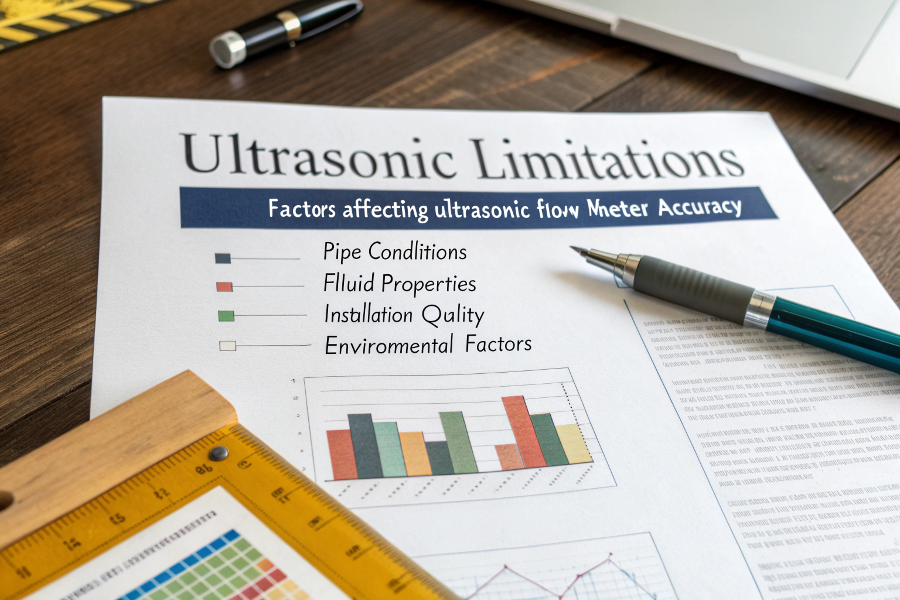

What Are The Limitations Of Ultrasonic Flow Meter?

Understanding limitations is crucial to avoid unexpected performance issues and measurement errors.

Ultrasonic flow meters can be affected by pipe conditions, fluid properties, installation quality, and environmental factors that may impact measurement accuracy.

Ultrasonic Flow Meter Limitations

Drawing from my implementation experience:

Common Limitations

-

Technical Constraints

Limitation Impact Solution Prevention Flow profile Accuracy loss Straight runs Proper installation Air bubbles Signal disruption De-aeration Process optimization Pipe coating Signal attenuation Surface preparation Regular maintenance Temperature changes Reading drift Compensation Temperature monitoring -

Installation Challenges

- Space requirements

- Pipe accessibility

- Environmental conditions

- Power availability

Mitigation Strategies

-

Design Considerations

- Proper sizing

- Location selection

- Environmental protection

- Backup systems

-

Operational Measures

- Regular maintenance

- Performance monitoring

- Staff training

- Documentation

What Is The Error Of Ultrasonic Flow Meter?

Understanding potential measurement errors helps in maintaining system accuracy and reliability.

Typical ultrasonic flow meter errors range from ±0.5% to ±2% of reading, with additional uncertainties possible due to installation and environmental factors.

Ultrasonic Flow Meter Error Analysis

Based on my field experience:

Error Sources

-

Contributing Factors

Error Source Typical Range Impact Control Method Installation ±0.5% Accuracy Proper setup Temperature ±0.2% Stability Compensation Flow profile ±0.3% Linearity Straight runs Signal processing ±0.1% Resolution Regular checks -

Error Management

- Regular calibration

- Performance monitoring

- Environmental control

- Maintenance scheduling

Quality Assurance

-

Verification Methods

- In-situ testing

- Comparative analysis

- Zero point checks

- Calibration records

-

Improvement Measures

- Staff training

- Process optimization

- Equipment upgrades

- Documentation

Conclusion

Ultrasonic flow meters provide excellent accuracy when properly selected, installed, and maintained, with typical errors of ±0.5% to ±2%, making them suitable for most industrial applications.