Last month, a water utility manager asked me why their new ultrasonic flow meter showed different readings from their old mechanical meter. The answer lies in understanding true measurement accuracy.

Modern ultrasonic flow meters can achieve accuracy rates of ±0.5% to ±1.0% of reading under optimal conditions. Their accuracy depends on installation quality, fluid properties, and operating conditions.

Ultrasonic Flow Meter Accuracy Overview

| Performance | |

|---|---|

| Flow Rate | ±0.03m/s~±12m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% of measured value |

| Linearity | ±1% |

| Pipe Size | DN25-DN1200 |

| Function | |

| Output | Analog output: 4-20mA, Max. load 750Ω ;Pulse output: 0~10KHz |

| Communication | RS232/RS485 Modbus(M-Bus or Hart is optional) |

| Power Supply | 10-36VDC / 90-245VAC |

| Display | 240*128 backlit LCD |

| Temperature | Transmitter:-20℃–60℃;Transducer:-40℃–80℃(TT01,TT02);Transducer:-40℃–130℃(TT03,TT05);Transducer:-40℃–180℃(TT02H);Transducer:0℃–65℃(TT02S);Transducer:0℃–135℃(TT03S) |

| Humidity | Up to 99%RH, non-condensing |

| Physical | |

| Transmitter | PC+ABS, IP65 |

| Transducer | Enccapulated design IP68;Double-shielded transducer cable;Standard/Max. cable length: 30ft/1000ft(9m/300m) |

I’ve tested hundreds of flow meters across various industries. Let me share what really determines their accuracy.

What Factors Impact Ultrasonic Flow Meter Accuracy?

A recent chemical plant installation showed 3% deviation until we identified and corrected issues with upstream flow disturbance and pipe conditions.

Key accuracy factors include fluid properties, pipe conditions, installation location, and environmental factors. Proper installation and calibration can help to maintain optimal accuracy levels.

Critical Accuracy Factors

Installation Requirements

Factor Impact on Accuracy Best Practice Common Issues Straight run Up to ±5% 10D upstream, 5D downstream Space constraints Flow profile Up to ±3% Flow conditioners Disturbance sources Mounting Up to ±2% Proper alignment Installation errors Pipe condition Up to ±1% Clean, scale-free surface Internal buildup Operating Parameters

- Flow velocity range

- Reynolds number

- Temperature variations

- Pressure fluctuations

How Do Ultrasonic Flow Meters Perform Across Different Industries?

During my field evaluations, I’ve seen remarkable consistency in water treatment applications but more challenges in chemical processing environments.

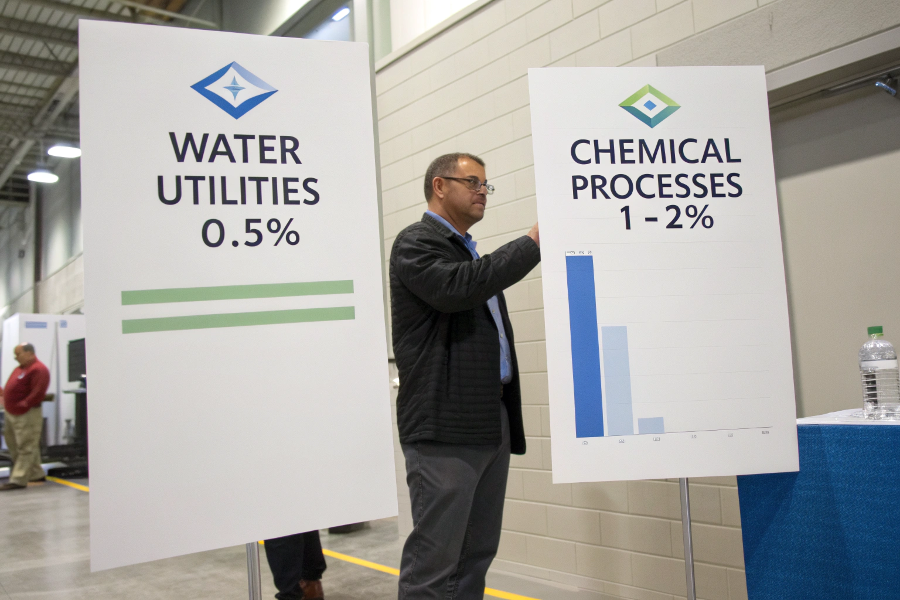

Industry performance varies significantly. Water utilities routinely achieve ±0.5% accuracy, while chemical processes might see ±1-2% due to more challenging conditions.

Industry-Specific Performance Data

Industry Performance Analysis

Accuracy by Application

Industry Typical Accuracy1 Key Challenges Success Factors Water/Wastewater ±0.5% Debris, air bubbles Clean fluid Chemical ±1-2% Corrosion, coating Material selection Oil & Gas ±1% Multi-phase flow Flow conditioning Power Generation ±0.7% High temperature Proper insulation

How Do Ultrasonic Meters Compare to Other Flow Technologies?

Last year, I conducted side-by-side testing of different flow technologies. The results revealed interesting accuracy patterns across operating ranges.

Ultrasonic meters often outperform mechanical meters in long-term accuracy and typically match or exceed electromagnetic meters in clean liquids. They maintain accuracy better over time with no moving parts.

Comparative Analysis

Technology Performance Matrix

Technology Accuracy Range Maintenance Needs Cost Factors Ultrasonic ±0.5-1% Low Initial investment Magnetic ±0.2-0.5% Medium Liner replacement Coriolis ±0.1-0.2% Low High initial cost Turbine ±1-2% High Regular rebuilds Long-term Accuracy Comparison

- Initial accuracy vs. long-term stability

- Maintenance impact on accuracy

- Cost of ownership considerations

- Application-specific performance

What Are the Best Practices for Maximizing Accuracy?

Recently, I helped a facility improve their measurement accuracy from ±2.5% to ±0.7% by implementing these specific practices.

Optimal accuracy requires proper sizing, careful installation planning, regular calibration, and ongoing maintenance. Following best practices can significantly improve measurement reliability.

Implementation Strategy

Accuracy Optimization Steps

Phase Action Items Expected Impact Verification Method Planning Site assessment Foundation for success Pre-installation check Installation Following guidelines Immediate accuracy Post-install verification Operation Regular monitoring Sustained performance Continuous validation Maintenance Scheduled checks Long-term reliability Periodic calibration Verification Program

- Regular calibration schedule

- Performance monitoring

- Data trending analysis

- Maintenance documentation

Conclusion

Ultrasonic flow meters can achieve excellent accuracy when properly selected, installed, and maintained. Their typical accuracy of ±0.5-1% makes them suitable for most industrial applications.

Want to achieve optimal accuracy in your application? Contact us for a detailed assessment and recommendations.

Understanding typical accuracy helps in evaluating performance standards across different sectors. ↩