Process engineers frequently question whether vortex meters can meet their measurement tolerances. The truth lies in understanding their performance envelope.

Vortex flow meters typically achieve ±1% of rate accuracy for liquids and ±1.5% for gases/steam under ideal conditions, with Rosemount models reaching ±0.65% for liquids. Their accuracy depends on proper installation, fluid properties, and velocity range (typically requiring >0.3 m/s).

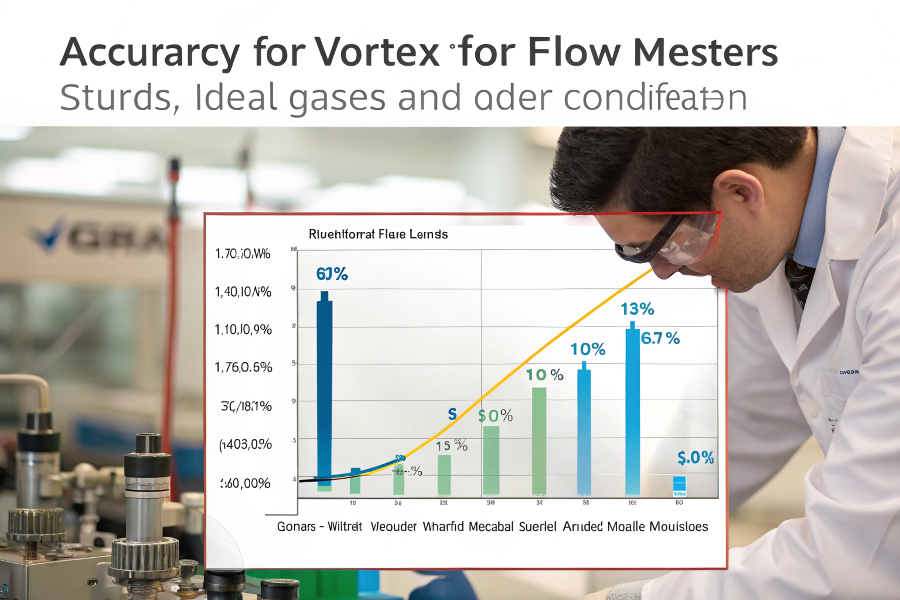

Accuracy Performance Curve

Three factors dominate vortex meter accuracy: fluid characteristics, installation conditions, and electronic signal processing.

How Accurate Is the Vortex Flow Meter?

Four key accuracy considerations:

Accuracy Comparison by Fluid Type

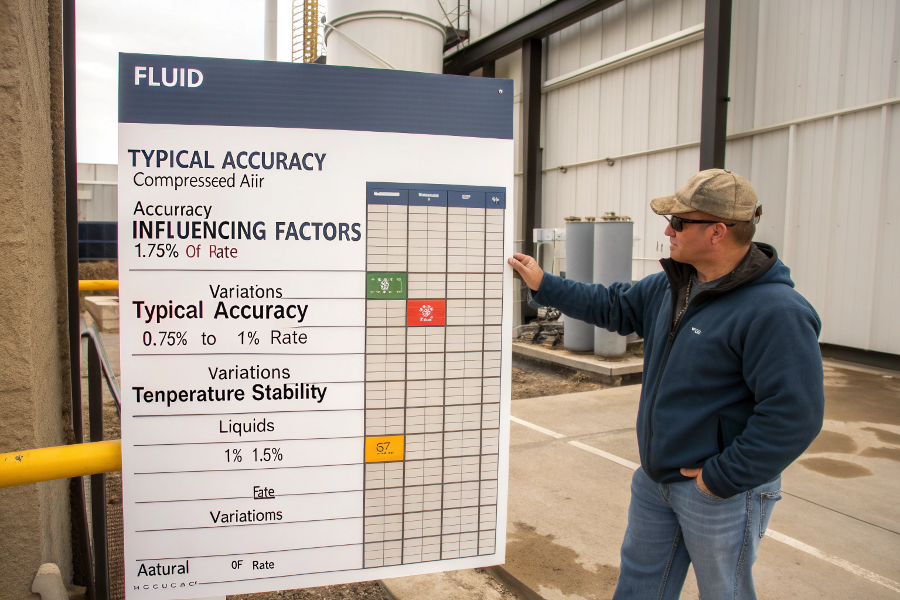

| Fluid | Typical Accuracy | Influencing Factors |

|---|---|---|

| Water | ±0.75% to ±1% of rate | Temperature stability |

| Steam | ±1% to ±1.5% of rate | Dryness fraction |

| Natural Gas | ±1% to ±1.75% of rate | Pressure variations |

| Compressed Air | ±1.25% to ±2% | Pulsation effects |

| Chemical Liquids | ±1% to ±1.5% | Viscosity changes |

Performance Variables

- Flow Profile – Requires 15D upstream straight pipe

- Vibration Levels – Digital filtering improves performance

- Temperature Swings – Affects K-factor calibration

- Density Changes – Requires compensation for gases

- Signal Processing – Advanced DSP boosts accuracy

Key Accuracy Influencers

Real-World Expectation Table

| Condition | Accuracy Impact |

|---|---|

| Ideal installation | Meets factory specs |

| Vibration present | +0.5% degradation |

| Poor flow profile | +1.0% error |

| Low flow rate | +2.0% deviation |

| Two-phase flow | Unpredictable |

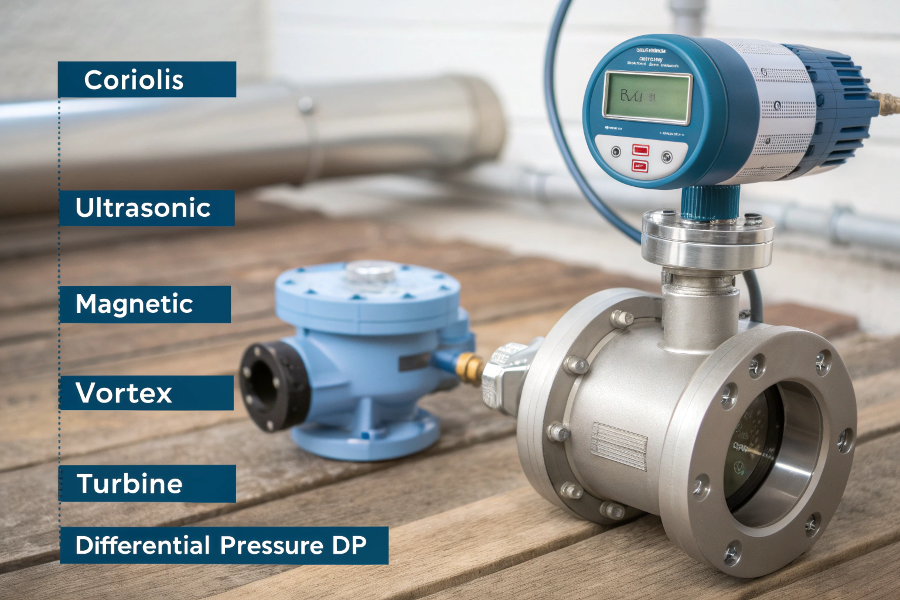

Which Flowmeter Has the Highest Accuracy?

Three technology tiers for precision measurement:

Accuracy Ranking Chart

| Meter Type | Best Case Accuracy | Typical Application |

|---|---|---|

| Coriolis | ±0.1% of rate | Custody transfer liquids |

| Ultrasonic | ±0.35% of rate | Large pipe gases |

| Magnetic | ±0.5% of rate | Conductive liquids |

| Vortex | ±0.65% of rate | Steam/gas processes |

| Turbine | ±0.75% of rate | Clean hydrocarbons |

| DP | ±1% of rate | General industry |

Technology Tradeoffs

- Coriolis: Highest accuracy but 3-5x vortex cost

- Ultrasonic: No pressure drop but complex installation

- Magnetic: Limited to conductive fluids

- Vortex: Balance of cost and performance

- Turbine: Moving parts require maintenance

- DP: Significant permanent pressure loss

Technology Accuracy Spectrum

Application-Specific Recommendations

- Custody Transfer: Coriolis (mandatory ±0.2%)

- Chemical Dosing: Coriolis or high-end vortex

- Steam Allocation: Vortex with temp/pressure comp

- Compressed Air: Vortex or ultrasonic

- Water Treatment: Magnetic or vortex

How Accurate Is a Flow Meter Reading?

Five reality checks for field accuracy:

Field vs Laboratory Conditions

| Factor | Lab Accuracy | Field Accuracy | Difference Cause |

|---|---|---|---|

| Calibration | ±0.25% | ±0.5% | Reference standard variances |

| Installation | ±0.1% | ±1.0% | Pipe configuration effects |

| Operation | ±0.15% | ±0.75% | Process condition changes |

| Maintenance | ±0.05% | ±0.5% | Sensor degradation |

| Environment | ±0.1% | ±0.3% | Temperature/humidity |

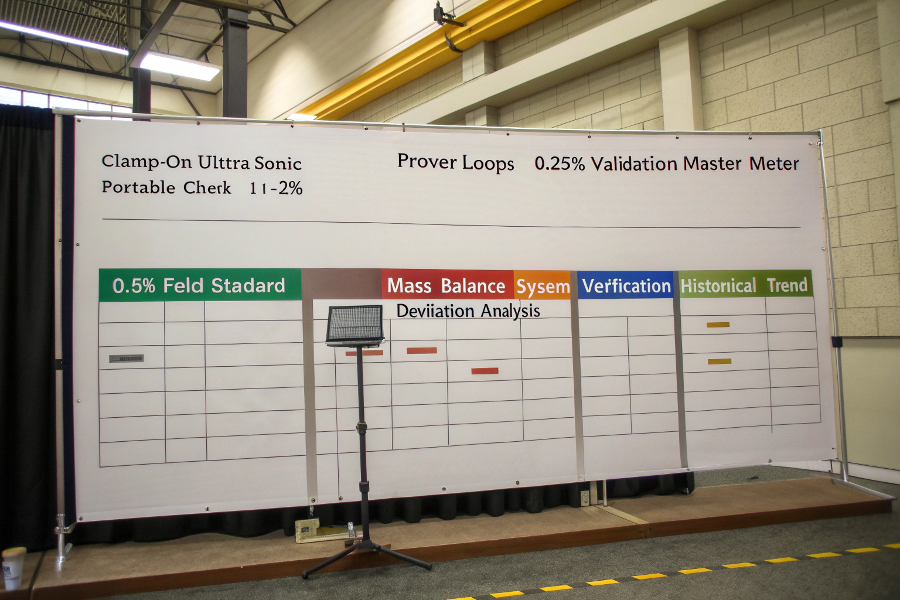

Accuracy Verification Methods

- Clamp-on Ultrasonic – Portable check ±1-2%

- Prover Loops – ±0.25% validation

- Master Meter – ±0.5% field standard

- Mass Balance – System verification

- Historical Trend – Deviation analysis

Field Verification Techniques

Practical Accuracy Tips

- Allow +0.5% minimum for field conditions

- Recalibrate every 3-5 years

- Monitor K-factor shifts

- Install flow conditioners when needed

- Use redundant meters for critical apps

How Accurate Is the Rosemount Vortex Flow Meter?

Three generations of performance evolution:

Rosemount Model Comparison

| Series | Liquid Accuracy | Gas Accuracy | Key Innovation |

|---|---|---|---|

| 8800D | ±0.65% | ±1% | Advanced DSP algorithms |

| 8800 | ±0.75% | ±1.15% | Improved sensor design |

| 8800C | ±1% | ±1.5% | Standard vortex tech |

Special Features Enhancing Accuracy

- MultiSensor Tech – Averages 2 sensing points

- Advanced Diagnostics – Detects installation issues

- Signal Validation – Rejects interference

- Density Compensation – For gas applications

- Temp-Stable Electronics – Minimizes drift

8800D Cutaway View

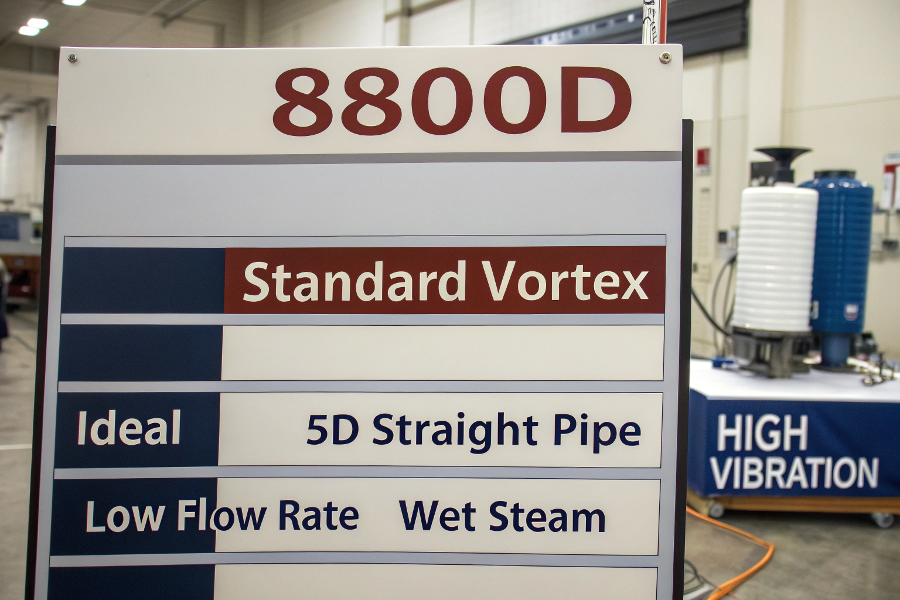

Installation-Specific Performance

| Condition | 8800D Accuracy | Standard Vortex Accuracy |

|---|---|---|

| Ideal | ±0.65% | ±1% |

| 5D straight pipe | +0.15% | +0.5% |

| High vibration | +0.2% | +0.8% |

| Low flow rate | +0.3% | +1.5% |

| Wet steam | +0.25% | +0.75% |

Conclusion

Vortex flow meters deliver reliable ±1% accuracy for most industrial steam and gas applications, with premium models like Rosemount 8800D achieving ±0.65% for liquids. While Coriolis meters offer higher precision, vortex technology provides the optimal balance of accuracy, reliability and cost for process measurement needs. Real-world accuracy depends on proper installation, regular maintenance, and selecting the right technology for each specific fluid and operating condition. Understanding these factors allows engineers to specify vortex meters where their performance characteristics match application requirements while choosing alternative technologies when higher precision becomes mandatory.