Choosing the right flow meter impacts your process efficiency. Different industries need different flow measurement solutions.

Electromagnetic flow meters excel in conductive liquid applications (water, acids, slurries) with ±0.5% accuracy and no moving parts, while other technologies like Coriolis (±0.1%) or ultrasonic (±1%) may better suit specific fluid properties or installation requirements.

Electromagnetic Flow Meters

After installing thousands of meters across industries, we’ve identified these key selection factors.

Which Type of Flowmeter Is Most Accurate?

Accuracy depends on application conditions.

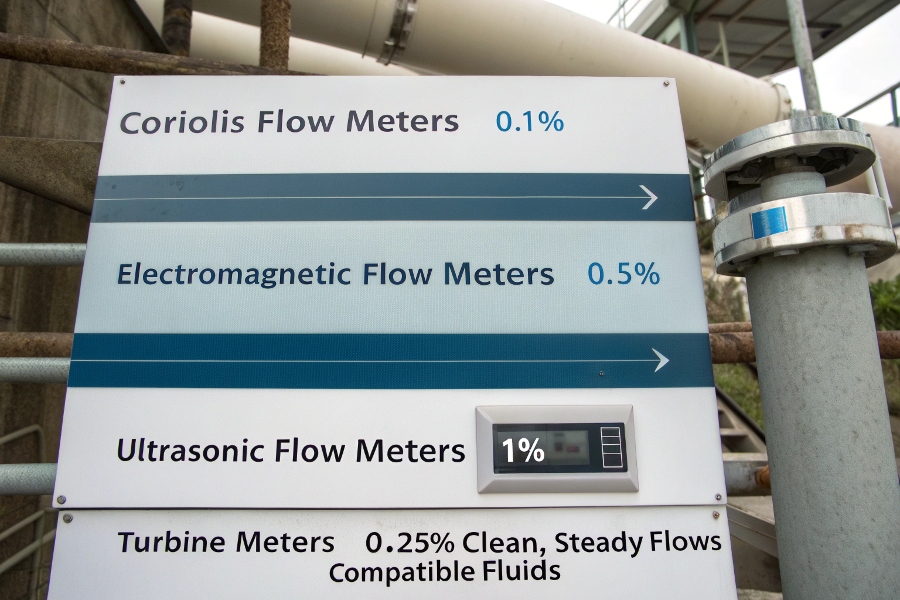

Coriolis flow meters provide the highest accuracy (±0.1%) for mass flow measurement, followed by electromagnetic (±0.5% for liquids) and ultrasonic (±1%), with turbine meters achieving ±0.25% in clean, steady flows of compatible fluids.

Flow Meter Accuracy Chart

Understanding accuracy ranges helps proper selection:

Accuracy vs. Application Matrix

| Flow Meter Type | Best Accuracy | Ideal Fluid | Limitations |

|---|---|---|---|

| Coriolis | ±0.1% | All liquids/gases | High cost, pressure drop |

| Electromagnetic | ±0.5% | Conductive liquids | Non-conductive fluids |

| Ultrasonic | ±1% | Clean liquids/gases | Requires calibration |

| Turbine | ±0.25% | Low-viscosity liquids | Wear with solids |

| Positive Displacement | ±0.5% | High viscosity | Moving parts maintenance |

Consider both specifications and real-world conditions.

What Are the Disadvantages of Electromagnetic Flow Meter?

Every technology has limitations.

Electromagnetic flow meters can’t measure non-conductive fluids (oils, gases), require full pipes, and may need frequent calibration in dirty applications, though they excel in conductive liquids like water or acids with minimal maintenance.

These limitations guide proper application:

Common EM Flow Meter Challenges

| Limitation | Industry Impact | Workarounds |

|---|---|---|

| Conductivity Requirement | No hydrocarbons/gases | Use Coriolis/ultrasonic |

| Full Pipe Needed | Air bubbles cause errors | Proper installation |

| Liner Degradation | Chemical compatibility | Material selection |

| Electrode Fouling | Dirty fluids problematic | Cleaning systems |

| Power Requirements | Needs energized coils | Backup power solutions |

Understanding these helps avoid misapplication.

What Is the Most Commonly Used Flow Measuring Device in Industry?

Usage varies by sector.

Electromagnetic flow meters dominate water/wastewater (60%+), while orifice plates lead in gas flow (45%), and Coriolis meters grow in chemical (30%) and food (25%) industries due to their versatility and direct mass measurement capability.

Flow Meter Industry Adoption

Industry-specific preferences emerge:

Industry Adoption Patterns

| Industry | Primary Type | Secondary Type | Reason for Choice |

|---|---|---|---|

| Water/Wastewater | Electromagnetic | Ultrasonic | Conductive fluids |

| Oil & Gas | Orifice Plate | Coriolis | Gas measurement |

| Chemical | Coriolis | Magnetic | Mass flow needs |

| Food & Beverage | Positive Displacement | Sanitary magnetic | Hygienic requirements |

| Pharmaceuticals | Coriolis | Thermal | Precision dosing |

Local regulations often influence selections.

What Is the Difference Between Electromagnetic Flowmeter and Ultrasonic Flow Meter?

Key distinctions guide selection.

Electromagnetic flow meters measure conductive liquids via magnetic fields (no moving parts), while ultrasonic meters use sound waves for liquids/gases (transit-time or Doppler), with EM being more accurate (±0.5% vs ±1%) but unable to measure non-conductive fluids.

Ultrasonic Flow Meters

Technical differences matter:

Feature-by-Feature Comparison

| Parameter | Electromagnetic | Ultrasonic | Advantage |

|---|---|---|---|

| Fluid Types | Conductive liquids | Liquids/gases | Ultrasonic more versatile |

| Accuracy | ±0.5% rate | ±1% rate | EM more precise |

| Installation | Requires full pipe | Clamp-on options | Ultrasonic easier |

| Pressure Drop | None | Minimal | Tie |

| Cost | Moderate | High-end options | EM typically cheaper |

| Maintenance | Low (no moving parts) | Medium (sensor issues) | EM wins |

Choose based on fluid properties first.

Conclusion

No single flow meter works for all applications – electromagnetic excels in conductive liquids, while other technologies better serve gases, non-conductives, or specialized needs. Match the technology to your fluid and process requirements.