Choosing the wrong electrode material can lead to costly flowmeter failures in corrosive environments. Understanding these three premium materials prevents measurement disasters.

Platinum electrodes excel in oxidating acids but cost 10× more than alternatives. Hastelloy C276 handles reducing acids better than titanium, while titanium Gr2 offers the best price/performance for chlorine environments. Material selection depends on pH, chemical compatibility, and budget constraints more than generic corrosion ratings.

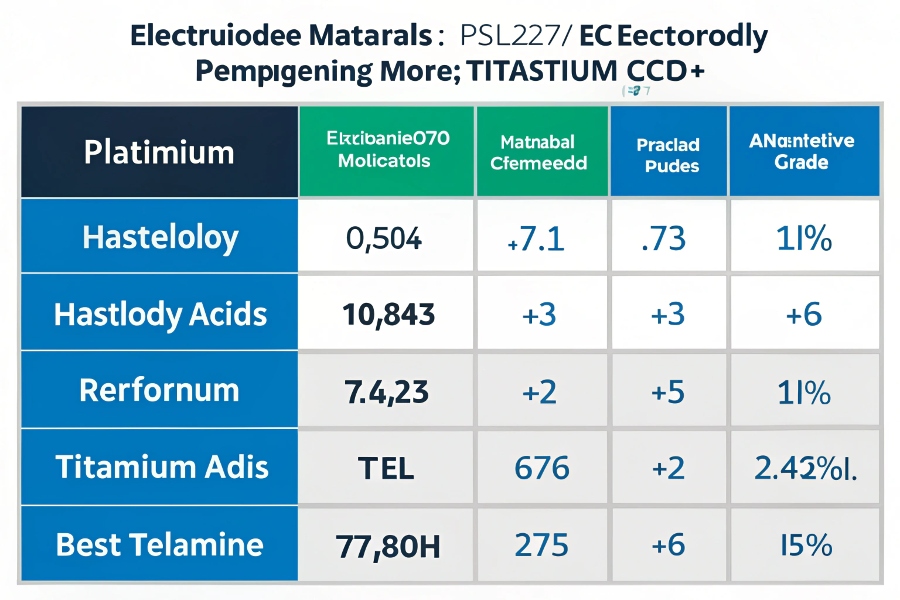

Material Selection Guide

Let’s examine these industrial workhorses in detail to match your specific process conditions.

Why is Platinum a Suitable Material for Electrodes?

The precious metal solution when nothing else survives.

Platinum’s impervious oxide layer (PtO₂) resists all acids except aqua regia, maintaining stable millivolt signals in 98% sulfuric acid and boiling nitric acid. Although costing $1,000+ per electrode, it becomes economical when replacement costs exceed material premiums for continuous processes.

Platinum Electrode Structure

Platinum dominates specific applications despite its price:

Platinum’s Niche Applications

| Application | Reason for Use | Alternative Viability |

|---|---|---|

| Electrowinning (Copper Refining) | Withstands FeCl₃/HCl electrolytes | None – others dissolve |

| 30% Chromic Acid Anodizing | Only material resisting Cr⁶⁶ oxidation | Hastelloy lasts <6 months |

| HF-Alkaline Mixes | Handles pH swings 0-14 | Ceramic electrodes fragile |

| Pharmaceutical CIP | Passes FDA extractables testing | Lower grade metals leach ions |

| Superconductive Cooling | -269°C performance | Other metals become brittle |

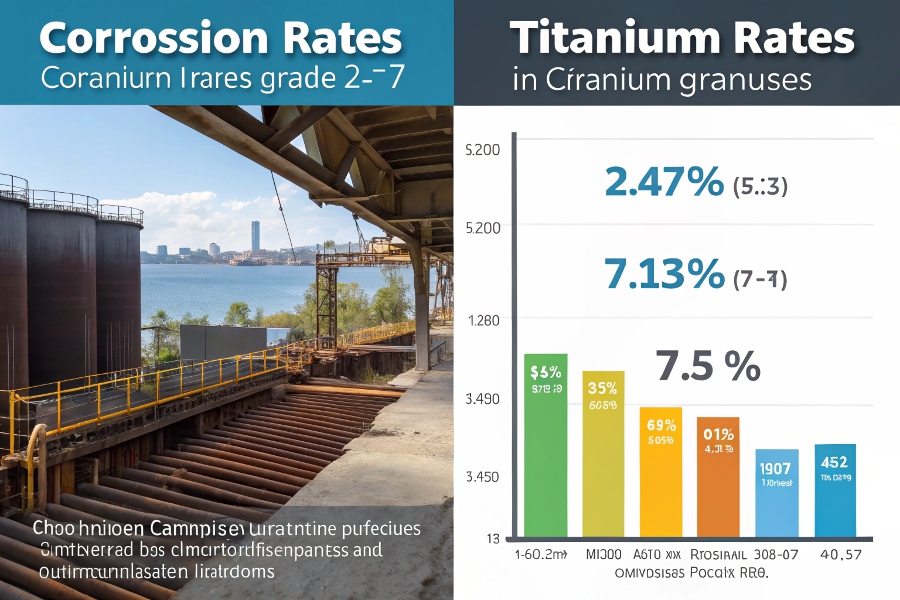

What is the Most Corrosion Resistant Titanium Alloy?

Grade 7 titanium (Ti-0.15Pd) outperforms standard grades.

Grade 7’s 0.15% palladium addition creates cathodic protection, reducing pitting in chlorides and oxidizing acids. While costing 3× more than Grade 2, it extends service life from <1 year to 5+ years in bleach (NaClO) and 15% HCl applications, proving cheaper long-term.

Ti Grade Corrosion Rates

Titanium varieties serve distinct purposes:

Titanium Selection Matrix

| Grade | Composition | Best For | Avoid |

|---|---|---|---|

| Gr1 | 99.5% Ti | Seawater cooling | Any reducing acids |

| Gr2 | Ti-0.3Fe | Chlorine gas lines | pH<2 sulfuric acid |

| Gr7 | Ti-0.15Pd | Hot brine systems | Fluoride solutions |

| Gr12 | Ti-0.3Mo-0.8Ni | Sulfide slurries | Nitric acid >60°C |

| Gr16 | Ti-0.05Pd | Nuclear condensate | Hydrofluoric acid |

Hastelloy’s Chemical Superiority

The nickel-based champion for reducing environments.

Hastelloy C276 (Ni-16Mo-16Cr-4W) withstands sulfuric and phosphoric acids that dissolve titanium. Its molybdenum-rich matrix resists chloride pitting better than platinum in neutral-to-acidic pH, making it ideal for chemical processing under $80/electrode.

Hastelloy vs Acids

Hastelloy subtypes address specific challenges:

Hastelloy Variant Comparison

| Alloy | Key Additions | Temperature Limit | Weakness |

|---|---|---|---|

| C22 | Higher Cr (21%) | 400°C | Cost premium |

| B3 | 28% Mo | 350°C | Oxidizing acids |

| G30 | 15% Co | 450°C | Sulfuric >80% |

| X | Fe-Ni-Mo-Cr | 1100°C | Aqueous corrosion |

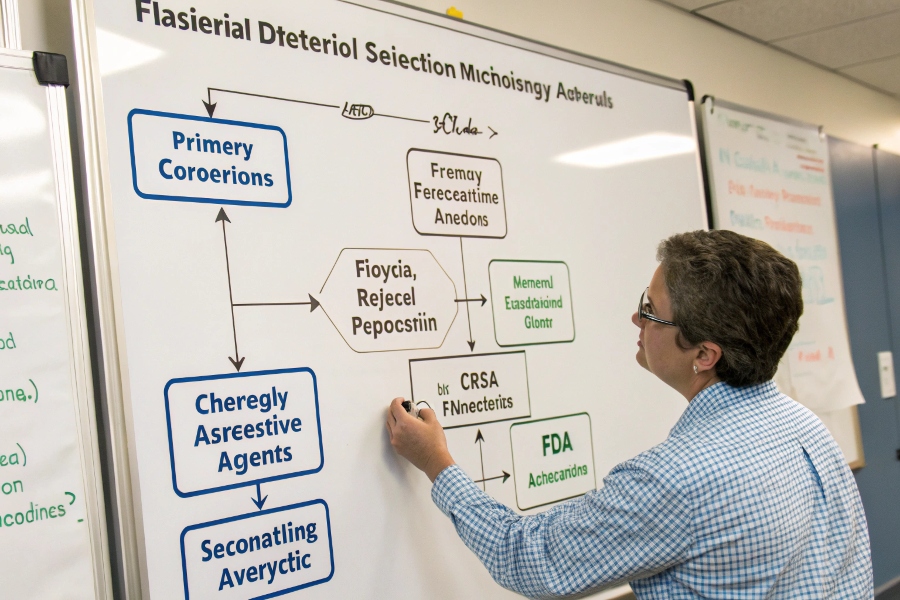

Material Selection Methodology

Seven-step decision process:

- Identify Primary Corrodent – Not just "acid" but specific ions (Cl⁻, F⁻, S²⁻)

- Check Redox Potential – Oxidizing (nitric) vs reducing (HCl) environments differ

- Temperature Extremes – Some materials passivate differently when hot

- Abrasion Factors – Hard-facing required for slurries >3% solids

- Electrochemical Effects – Stray currents accelerate corrosion

- FDA/NSF Requirements – Platinum needed for ultrapure processes

- Total Cost Analysis – Include replacement labor/downtime costs

Decision Tree

Cost-Performance Tradeoffs

| Material | Initial Cost | Life Expectancy | Effective Annual Cost |

|---|---|---|---|

| Platinum | $1,200 | 10-15 years | $80-120/year |

| Hastelloy | $320 | 3-5 years | $64-107/year |

| Ti Gr7 | $280 | 5-7 years | $40-56/year |

| Ti Gr2 | $110 | 1-3 years | $37-110/year |

| SS316L | $85 | <1 year | $85+/year |

Installation Best Practices

Even premium materials fail if installed incorrectly.

- Electrical Isolation – Prevent galvanic corrosion with PTFE gaskets

- Flow Direction – Orient electrodes opposite pipe weld seams

- Gasket Compression – 30-40 N·m torque prevents crevice corrosion

- Cable Routing – Separate from power lines to avoid stray currents

- Grounding – Use dedicated ground rings for lined pipe

Emerging Alternatives

New materials entering the market:

- Graphene-Coated Electrodes – Combines platinum’s corrosion resistance with lower cost

- Additive Manufactured Alloys – Custom metal matrix compositions

- Conductive Ceramics – Silicon carbide options for extreme temps

Conclusion

Platinum remains unbeatable for oxidizing acids despite its cost, while Hastelloy dominates reducing environments. Titanium Grade 7 offers the smart compromise for chloride services. The "best" material depends on your specific chemical exposure, temperature profile, and total cost considerations—not generic corrosion tables. Always conduct real fluid immersion tests before final selection, as minor contaminants often dictate material performance more than bulk chemistry.