Many plant operators face unexpected measurement failures when using magnetic flow meters with low-conductivity fluids.

Fluid conductivity directly affects magnetic flow meter performance, with a minimum requirement of 5 μS/cm for standard meters. Lower conductivity leads to unreliable measurements or complete meter failure.

I’ve seen numerous cases where understanding conductivity requirements could have prevented costly measurement errors.

What Is The Conductivity Requirement For Magnetic Flow Meter?

Many users struggle with selecting the right magnetic flow meter for their application due to conductivity concerns.

Standard magnetic flow meters require minimum fluid conductivity of 5 μS/cm, while specialized meters can measure down to 1 μS/cm with reduced accuracy.

From my field experience:

Conductivity Requirements by Application

Industry Standards

Application Min. Conductivity1 Typical Accuracy Notes Process Water 5 μS/cm ±0.5% Standard use Demineralized Water 1-5 μS/cm ±1.0% Special design Chemical Process >20 μS/cm ±0.3% Best performance Slurries >100 μS/cm ±0.5% Abrasion resistant - Temperature effects

- Chemical composition

- Pressure influence

- Flow velocity impact

Optimization Methods

Installation Considerations

- Proper grounding

- Electrode material

- Liner selection

- Signal processing

Performance Enhancement

- Regular calibration

- Conductivity monitoring

- Temperature compensation

- Signal verification

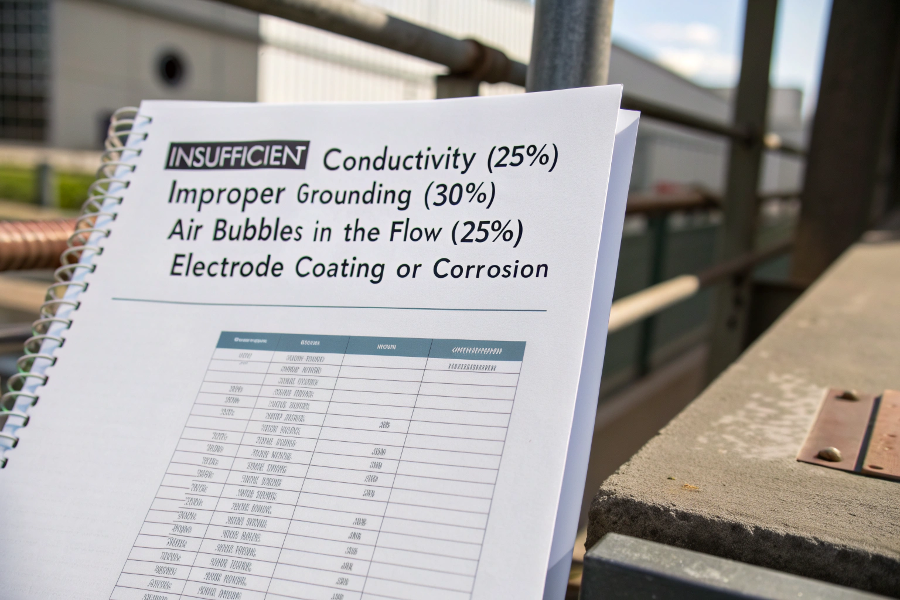

What Causes Errors In A Magnetic Flow Meter?

Understanding error sources helps prevent measurement inaccuracies and system failures.

Common error sources include insufficient conductivity, improper grounding, air bubbles in the flow, and electrode coating or corrosion.

Magnetic Flow Meter Error Sources

Based on my troubleshooting experience:

Error Analysis

Common Problems

Error Source Impact Solution Prevention Low Conductivity3 No Signal Fluid Treatment Proper Selection Poor Grounding Noise Better Grounding Regular Checks Air Bubbles Spikes Air Elimination Installation Design Coating Signal Loss Cleaning Material Selection Environmental Factors

- Temperature variations

- Electromagnetic interference4

- Vibration effects

- Chemical exposure

Solution Strategies

Preventive Measures

- Regular maintenance

- Process monitoring

- Staff training

- Documentation

Corrective Actions

- Troubleshooting procedures

- Calibration checks

- Component replacement

- Process optimization

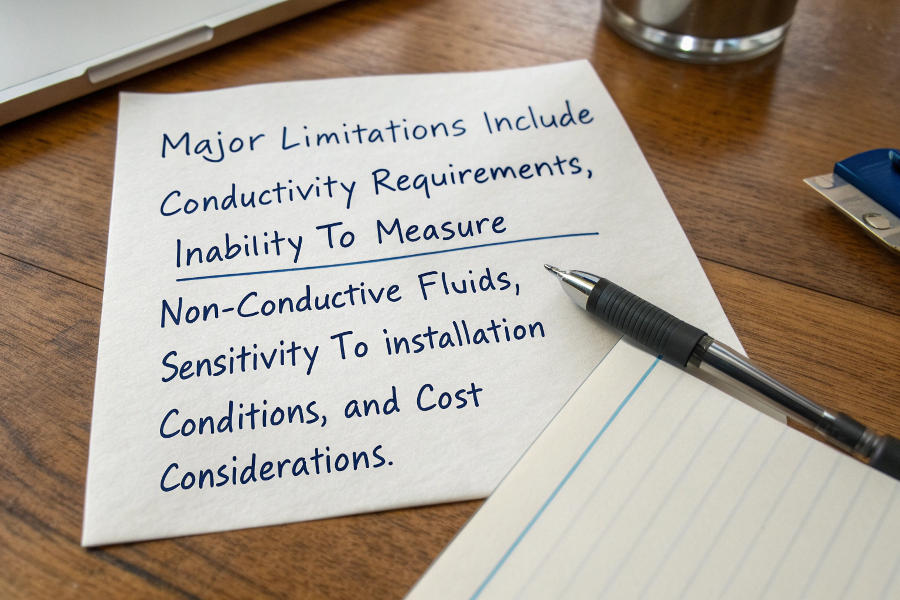

What Are The Limitations Of An Electromagnetic Flow Meter?

Understanding limitations helps in proper application selection and prevents misuse.

Major limitations include conductivity requirements, inability to measure non-conductive fluids, sensitivity to installation conditions, and cost considerations.

Electromagnetic Flow Meter Limitations

From my application experience:

Limitation Categories

Technical Constraints

Limitation Impact Alternative Consideration Conductivity No Measurement Different Technology Application Review Installation Accuracy Loss Better Location Space Planning Maintenance Cost Impact Simplified Design Budget Planning Environment Performance Issues Protection Site Assessment Application Constraints

- Fluid properties

- Process conditions

- Installation space

- Budget limitations

Management Strategies

Design Considerations

- Alternative technologies

- Hybrid solutions

- Cost optimization

- Performance requirements

Implementation Plans

- Installation guidelines

- Maintenance schedules

- Training programs

- Documentation systems

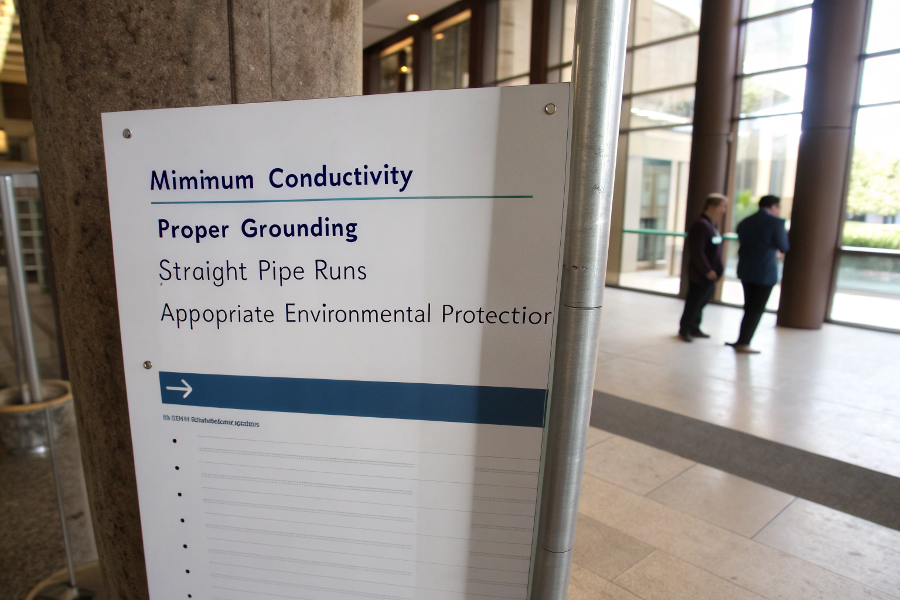

What Are The Requirements For A Magnetic Flow Meter?

Proper installation and operation require understanding specific requirements.

Key requirements include minimum conductivity, proper grounding, straight pipe runs, and appropriate environmental protection.

Magnetic Flow Meter Requirements

Drawing from my installation experience:

Installation Requirements

Physical Requirements

Requirement Specification Purpose Verification Straight Run 5D Upstream Flow Profile Inspection Grounding Multiple Points Signal Quality Testing Protection IP67 Minimum Environmental Certification Power Supply Stable Source Operation Monitoring Process Requirements

- Flow conditions

- Pressure limits

- Temperature range

- Chemical compatibility

Operation Requirements

Maintenance Needs

- Regular calibration

- Electrode cleaning

- Signal verification

- Documentation

Performance Monitoring

- Accuracy checks

- Zero point verification

- Span validation

- Error monitoring

Conclusion

Conductivity significantly affects magnetic flow meter performance, making proper understanding of requirements, limitations, and error sources essential for successful application and operation.

Understanding Min. Conductivity is crucial for ensuring optimal performance in various water applications. ↩

Exploring Conductivity Factors helps in optimizing processes and improving water quality management. ↩

Understanding low conductivity can help you mitigate signal issues in electrical systems. ↩

Exploring this topic will provide insights into protecting devices from interference. ↩