Water level measurement errors can cause serious operational problems in water treatment and storage facilities.

Yes, you can measure water level using pressure. A differential pressure transmitter measures water level by detecting the hydrostatic pressure created by the water column, where 1 meter of water equals approximately 0.098 bar of pressure.

Water Level DP Measurement

Let me share our experience with water applications using differential pressure transmitters.

Can You Measure Water Level With Pressure?

Many facility managers worry about the accuracy of water level measurements.

Pressure-based water level measurement is highly accurate and reliable. The hydrostatic pressure at the bottom of a water column directly correlates to the height of water above the sensor.

Water Level Pressure Measurement

From our practical experience:

Measurement Principles

Key Factors

Factor Relationship Consideration Water Height Linear 1m = 0.098 bar Temperature Affects density Compensation needed Installation Depth placement Access requirements Accuracy ±0.1% typical Application dependent Application Types

- Storage tanks

- Wells and boreholes

- Water treatment plants

- Reservoirs

Implementation Guidelines

Setup Requirements

- Sensor placement

- Cable protection

- Ventilation system

- Calibration points

Best Practices

- Regular maintenance

- Zero checking

- Span verification

- Documentation

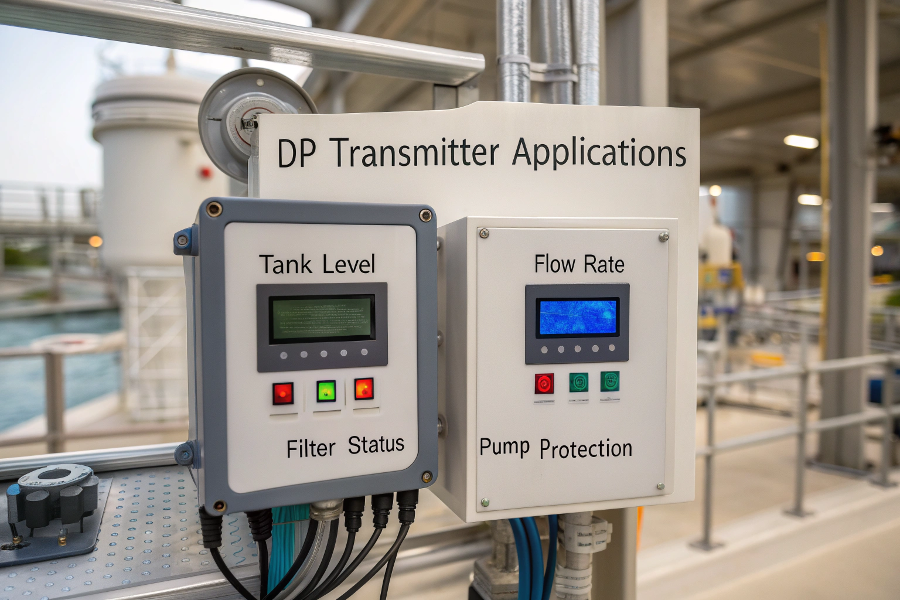

What Is A Differential Pressure Transmitter Used For?

Understanding the versatility of DP transmitters helps in optimal application selection.

A differential pressure transmitter measures the pressure difference between two points and can be used for level, flow, density, and interface measurements in various water applications.

DP Transmitter Applications

Based on our industry experience:

Common Applications

Water Industry Uses

Application Purpose Benefits Tank Level Storage monitoring Inventory control Flow Rate Process control Efficiency Filter Status Maintenance timing Cost reduction Pump Protection Equipment safety Reliability Selection Criteria

- Process conditions

- Accuracy needs

- Installation requirements

- Maintenance access

Technical Considerations

Design Factors

- Pressure range

- Material compatibility

- Environmental protection

- Output signals

Performance Aspects

- Response time

- Long-term stability

- Temperature effects

- Calibration needs

What Is A Pressure Transducer For Water Level Measurement?

Selecting the right pressure transducer is crucial for accurate water level monitoring.

A pressure transducer for water level measurement is a device that converts hydrostatic pressure into an electrical signal, typically 4-20mA, proportional to the water level.

Pressure Transducer Types

Drawing from our technical expertise:

Transducer Types

Common Configurations

Type Operation Application Submersible Direct contact Deep wells External Non-contact Clean tanks Sanitary Hygienic Drinking water Smart Digital output Remote monitoring Key Features

- Accuracy ratings

- Protection class

- Output options

- Material options

Application Guidelines

Selection Factors

- Installation depth

- Water quality

- Environmental conditions

- Maintenance access

Performance Requirements

- Measurement range

- Resolution

- Response time

- Long-term stability

What Is Differential Water Pressure?

Understanding differential water pressure is essential for proper system design.

Differential water pressure is the pressure difference between two points in a water system, used for measuring level, flow, or pressure drop across filters and other equipment.

Water Differential Pressure Concept

Based on our field experience:

Understanding DP in Water Systems

Common Applications

Application Measurement Purpose Filter Systems Pressure drop Maintenance timing Pump Performance Discharge-suction Efficiency monitoring Level Measurement Height difference Volume calculation Flow Control Pressure difference Rate monitoring Critical Factors

- System design

- Operating conditions

- Measurement points

- Maintenance needs

Implementation Strategy

System Requirements

- Range selection

- Installation points

- Signal processing

- Calibration needs

Operational Considerations

- Regular maintenance

- Data logging

- Alarm settings

- Performance tracking

Conclusion

Successful water measurement using differential pressure transmitters requires proper understanding of principles, careful selection of equipment, and regular maintenance to ensure accurate and reliable operation.