Incorrect flow meter installation can lead to measurement errors, equipment damage, and process inefficiencies.

Ultrasonic flow meters can be installed vertically, but proper orientation and installation guidelines must be followed to ensure accurate measurements and prevent air entrapment.

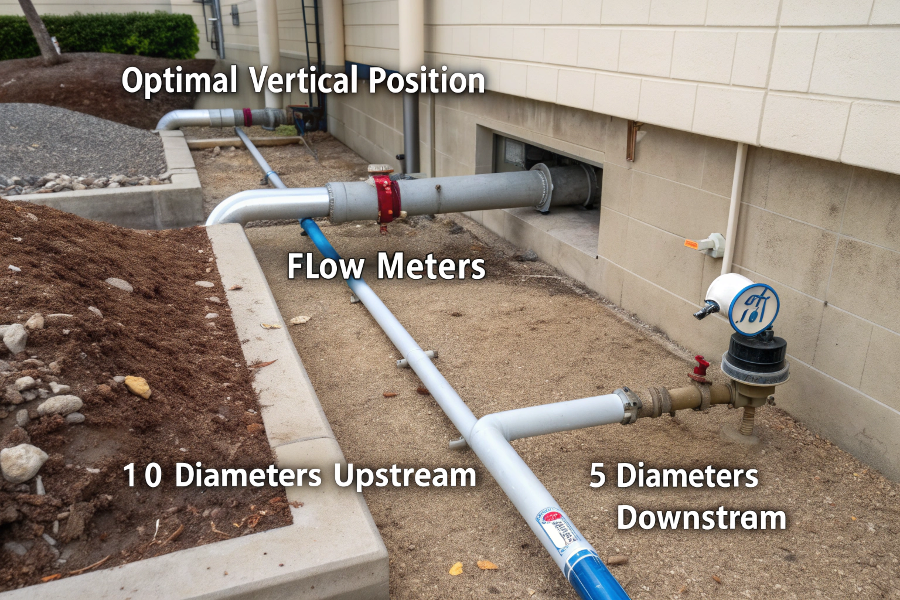

Vertical Flow Meter Installation

I’ve helped numerous customers with flow meter installations, and I’ll share key insights to ensure your vertical installation succeeds.

Can a Flow Meter Be Installed Vertically?

Many installers worry about vertical installations affecting measurement accuracy.

Yes, flow meters can be installed vertically, but the flow direction should be upward to ensure pipe remains full and air bubbles naturally escape.

Vertical Flow Direction

Vertical Flow Direction

From my installation experience:

Vertical Installation Considerations

-

Key Factors

Factor Requirement Reason Flow direction Upward Prevents air pockets Pipe fill 100% full Ensures accuracy Mounting Secure Prevents vibration Access Maintenance space Enables service -

Critical Requirements

- Proper support structure

- Correct orientation

- Adequate straight runs

- Appropriate isolation

Installation Best Practices

-

Pre-Installation Checks

- Site assessment

- Space verification

- Support evaluation

- Flow conditions

-

Installation Steps

- Alignment verification

- Secure mounting

- Level checking

- Signal testing

What Is The Vertical Position of a Flow Meter?

Understanding proper positioning is crucial for measurement accuracy.

The optimal vertical position for flow meters is in an upward flow section, with straight pipe runs of 10 diameters upstream and 5 diameters downstream.

Flow Meter Position Requirements

Based on my field experience:

Position Requirements

-

Installation Dimensions

Location Requirement Purpose Upstream 10D minimum Flow profile Downstream 5D minimum Stability Support points 2-3 locations Stability Access space 1m clearance Maintenance -

Location Considerations

- Flow profile effects

- Pipe support needs

- Maintenance access

- Environmental factors

Positioning Guidelines

-

Measurement Accuracy

- Profile development

- Signal strength

- Noise reduction

- Stability factors

-

Practical Aspects

- Installation ease

- Maintenance access

- Safety considerations

- Cost effectiveness

What Flow Meter Can Be Used Upright?

Selecting the right meter type is essential for vertical installations.

Several flow meter types work well in vertical installations, including ultrasonic, magnetic, vortex, and Coriolis meters, each with specific installation requirements.

Vertical Flow Meter Types

Drawing from my selection experience:

Meter Type Comparison

-

Vertical Compatibility

Meter Type Suitability Limitations Ultrasonic Excellent Needs full pipe Magnetic Very good Conductive fluids Vortex Good Min velocity Coriolis Excellent Cost/size -

Application Factors

- Fluid properties

- Flow conditions

- Space constraints

- Budget limitations

Selection Criteria

-

Technical Requirements

- Flow range

- Accuracy needs

- Process conditions

- Installation space

-

Practical Considerations

- Installation costs

- Maintenance needs

- Support requirements

- Life cycle costs

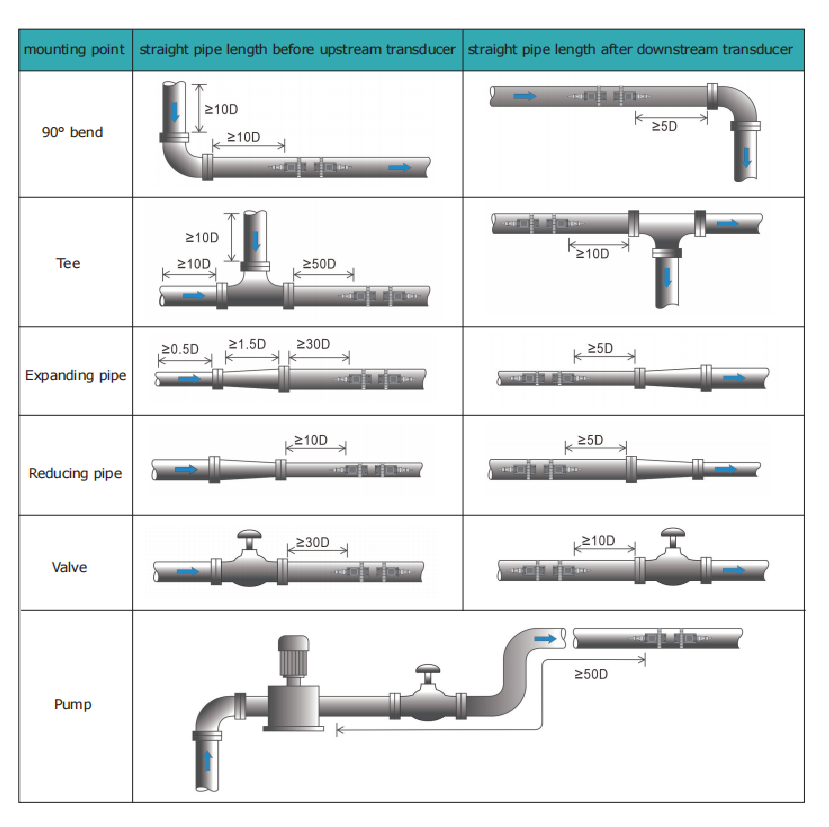

What Is The Rule of Thumb for Flow Meter Installation?

Following basic installation rules prevents common problems.

The primary rule is maintaining straight pipe runs of 10 diameters upstream and 5 diameters downstream, with proper support and full pipe conditions.

Flow Meter Installation Rules

Based on my installation expertise:

General Rules

-

Installation Guidelines

Rule Requirement Purpose Straight run 10D/5D Flow profile Pipe fill 100% Accuracy Support Every 3D Stability Orientation Flow arrow Direction -

Critical Factors

- Flow conditioning

- Vibration control

- Temperature effects

- Pressure considerations

Implementation Steps

-

Planning Phase

- Site survey

- Documentation review

- Resource allocation

- Schedule planning

-

Execution Phase

- Installation sequence

- Quality checks

- Testing procedures

- Documentation

Conclusion

Successful vertical flow meter installation requires proper positioning, adequate straight runs, and following manufacturer guidelines while considering specific application requirements.