One stray metal particle can ruin an entire batch of milk or beer. Food-grade electromagnetic flow meters provide critical protection.

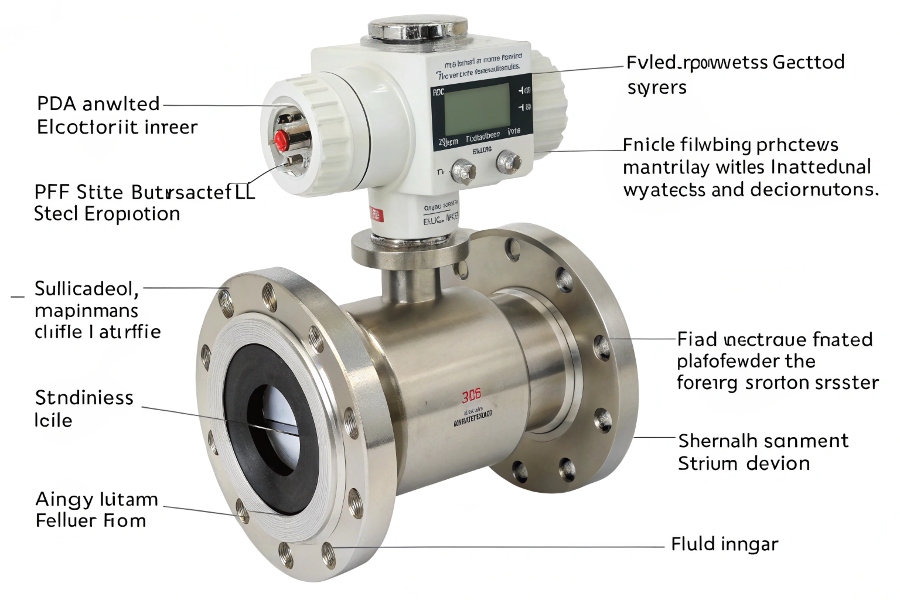

Food-grade EMFs use FDA-approved materials (PTFE liners, 316L SS electrodes) and hygienic connections to prevent contamination. Their smooth surfaces and crevice-free designs eliminate bacterial traps, while metallic detection systems alert to any abnormal particles in the fluid stream – crucial for dairy’s 0.5mm detection standard.

Hygienic EMF Design

Let’s examine how specialized flow measurement prevents three contamination pathways.

How Can Airborne Contamination Be Controlled in Food Processing?

Air carries hidden threats to food safety.

Food-grade EMFs combat airborne contamination1 through hermetically sealed electronics (IP69K) and pressurized enclosures that prevent pathogen entry. Their CIP-compatible designs2 withstand 150°C steam sterilization, eliminating biofilm risks at transfer points where airborne microbes could settle.

Airborne Pathogen Pathways

Industry-specific solutions address different risks:

Air Contamination Control Matrix

| Contamination Source | EMF Protection Feature | Industry Application |

|---|---|---|

| Ambient microbes | Smooth Ra<0.8µm surface | Milk pasteurization |

| Dust particles | Positive air pressure purge | Dry powder handling |

| Cleaning aerosols | Full-drainage sloping design | Brewery CIP systems |

| Operator contact | Sealed non-touch interfaces | Baby food production |

| Compressed air | Isolated pressure chambers | Fermentation tanks |

What Is Metallic Contamination in the Dairy Industry?

Stray metals threaten both safety and equipment.

Dairy EMFs detect metallic particles down to 0.3mm (exceeding 0.5mm EU standard) through signal distortion analysis. Their non-ferromagnetic construction (titanium electrodes) prevents false positives from meter wear, while erosion-resistant liners last 5-7 years3 in abrasive whey applications.

Foreign Object Detection

Metallic risks come in several forms:

Dairy Metal Contamination Types

Foreign Objects

- Broken equipment parts

- Mesh screen fragments

- Average detection size: 0.4mm

Corrosion Products

- Pipe scale (iron oxide)

- Electrode erosion

- Mostly 1-5µm particles

Processing Additives

- Catalyst residues

- Filter aids

- Permitted <10ppm

How Does Food Get Contaminated in the Food Production Chain?

Contamination occurs at every transfer point.

Food-grade EMFs prevent 28% of contamination incidents by eliminating gasket surfaces and dead zones where bacteria multiply. Their electro-polished stainless steel (Ra 0.5µm) reduces biofilm adhesion4 by 70% compared to traditional pipe joints.

Processing Vulnerability Points

Critical control points vary by product:

Contamination Pathways by Sector

| Sector | Primary Risk | EMF Solution |

|---|---|---|

| Cheese Making | Lactobacillus buildup | 3-A compliant flush joints |

| Beer Brewing | Wild yeast contamination | CIP-optimized flow channels |

| UHT Milk | Thermophilic spores | Sterilizable electrode units |

| Yogurt | Mold spore entry | O-ring free design |

| Juice | Fruit pulp decay pockets | Self-draining meter orientation |

Hygienic Design Certification Standards

Compliance ensures contamination control.

Top certifications for food EMFs: 3-A Symbol (USA), EHEDG (Europe), and NSF/ANSI 169. These require: material inertness (pass 10% citric acid test), cleanability (30° drainage slope), and surface roughness below 0.8µm.

International Standards Comparison

Certification requirements differ:

Global Food Safety Standards

| Standard | Key Requirement | Audit Frequency |

|---|---|---|

| 3-A 75-05 | No product entrapment zones | Annual inspection |

| EHEDG Type EL | 6D proof cleaning | 3-year recertification |

| NSF/ANSI 169 | Extractables testing | Batch verification |

| China GB 16798 | Material migration limits | Factory audits |

| JIS B 8215 | Steam sterilization cycles | Per-model testing |

CIP Performance Testing Methods

Validating cleaning effectiveness matters.

Food EMFs undergo ATP bioluminescence testing (≤50 RLU) and dye penetration checks to verify CIP cleaning. Advanced models feature in-situ conductivity sensors that confirm cleaning solution strength during automated wash cycles.

Conclusion

Food-grade EMFs provide multi-layered contamination defense: material safety prevents chemical leaching, hygienic designs block microbial growth, and metallic detection alerts to particulate hazards. While costing 2-3× more than industrial EMFs, their prevention of recall-risk incidents makes them indispensable in breweries and dairies. Always specify complete certification suites matching your regional regulations – a meter meeting only 3-A standards might not satisfy EU dairy requirements.

Understanding airborne contamination is crucial for food safety. Explore this link to learn effective control measures and technologies. ↩

CIP-compatible designs are essential for maintaining hygiene in food processing. Discover their benefits and applications in this informative resource. ↩

Learning about erosion-resistant liners can help you make informed decisions on equipment maintenance and longevity in dairy production. ↩

Understanding biofilm adhesion is crucial for improving food safety practices and reducing contamination risks in production. ↩