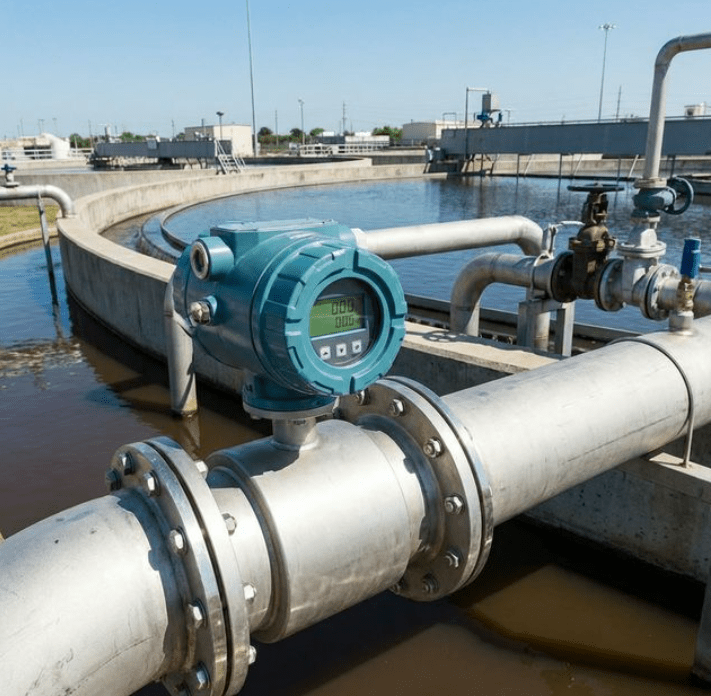

Turbine Flow Meter Troubleshooting: How to Fix Common Issues?

Flow meter problems can disrupt operations and lead to costly mistakes in measurement. When troubleshooting turbine flow meters, check for physical damage, verify power supply,

Flow meter problems can disrupt operations and lead to costly mistakes in measurement. When troubleshooting turbine flow meters, check for physical damage, verify power supply,

Understanding the mechanics behind turbine flow meters is essential for effective implementation. The working principle of a turbine flow meter is based on the movement

Selecting the right flow meter for water applications is vital for accuracy and reliability. A turbine flow meter utilizes a rotor or turbine within the

Incorrect straight run lengths can impact turbine flow meter readings drastically and affect operational accuracy. The standard straight run requirement for a turbine flow meter

Determining the K-factor in turbine flow meters can be tricky, yet essential for accurate flow measurements. The K-factor is calculated by dividing the number of

Incorrect turbine flow meter installation can result in inaccurate measurements, affecting operations significantly. For optimal results, install the turbine flow meter with at least 10

Precision measurement matters in industries where a 1% error can cost $100,000 annually. Turbine meters solve this problem for specific fluid types. The primary advantage

Precision flow measurement drives efficiency in industries managing over $3 trillion in liquid products annually. Turbine meters deliver accuracy where it matters most. Turbine flow

When fluid flows past an obstruction, it creates swirling patterns that reveal precise flow rates. This natural phenomenon powers over 2 million industrial vortex meters

Nearly 35% of uncalibrated vortex meters develop measurement errors exceeding 2% within 12 months. Proper calibration maintains accuracy for custody transfer and process control applications.

Over 60% of vortex meter issues stem from incorrect installation rather than device failure. Early problem detection can prevent costly process interruptions and measurement errors.

Plant operators frequently underestimate vortex meter pressure drops, risking flow capacity reduction and increased pump costs by 5-10%. Small pressure losses accumulate into significant energy

Process engineers frequently overlook straight-run distances, not realizing these requirements can affect measurement accuracy by 5-10%. Small installation errors cause big operational problems. Vortex flow

Many technicians assume vortex meters work equally well in all orientations – until measurement errors appear. Orientation impacts performance more than expected. Vortex flow meters

Process engineers often underestimate piping requirements, resulting in measurement errors up to 5%. Correct straight-run distances prevent these costly mistakes. Vortex flow meters typically require

Process engineers frequently question whether vortex meters can meet their measurement tolerances. The truth lies in understanding their performance envelope. Vortex flow meters typically achieve

Factory engineers often struggle finding flow measurement solutions for steam and aggressive gases. Vortex flow meters solve these challenges with their unique non-contact measurement principle.

Plant managers often face costly measurement errors with traditional flow technologies in steam and gas applications. Vortex flow meters offer reliable alternatives with minimal maintenance

Standard flow meters often fail in specialized small pipe applications, costing companies thousands in inaccurate measurements and downtime. Custom ultrasonic solutions solve these precision challenges.

Lost revenue from flow measurement errors often goes unnoticed until audits reveal shocking losses. Ultrasonic technology provides the financial visibility needed for small pipe systems.

Getting flow measurement wrong in small pipes can cost thousands in errors. The right meter prevents these mistakes while maximizing performance. Selecting the correct flow

Measuring flow in small pipes demands precision traditional methods can’t deliver. Ultrasonic technology rises to this challenge with groundbreaking accuracy. Ultrasonic flow meters achieve ±0.5-1%

Flow measurement in pipes under 2 inches has always been challenging. Traditional methods struggle with accuracy in tight spaces, but ultrasonic technology breaks through these

Struggling with flow measurement in pipes under 25mm diameter? Conventional flow meters often fail in small pipes, but modern ultrasonic technology delivers remarkable precision where

Frustrated by inaccurate flow measurements in your narrow pipelines? Compact ultrasonic flow meters solve unique small-pipe challenges traditional meters can’t handle. Even 0.1mm alignment errors

Struggling to measure flow accurately in narrow pipelines? Small diameter pipes present unique challenges for ultrasonic flow measurement that demand specialized solutions. Traditional clamp-on models

Seeing unexpected flow measurement errors when temperatures change? Temperature impacts every flow meter type differently, often causing significant reading deviations if not properly managed. Even

Need to measure flow in extreme temperature conditions? Ultrasonic flow meters handle surprisingly wide temperature ranges, but performance varies significantly by design and model. Understanding

When a pharmaceutical client rejected three standard ultrasonic meters last month, our custom-configured 1" solution with high-frequency sensors solved their low-flow measurement problem permanently. This

There is a real story. One of my friend told me that he’ll never forget the time he spent three days troubleshooting a clamp-on meter

I’ve seen countless costly mistakes from improper ultrasonic flow meter installations. Poor installation can lead to measurement errors of up to 20% and thousands in

When we installed our first clamp-on meter without checking pipe conditions, we got readings that varied by 15% – until we discovered the hidden flow

During a recent plant audit, we counted 47 ultrasonic flowmeters monitoring everything from chilled water to diesel fuel – each chosen for specific advantages over

When our plant’s main water line needed flow monitoring without shutdown, we tried an ultrasonic meter. The initial excitement faded when fluctuating readings appeared during

After spending $23,000 to replace a seized turbine meter in a chemical plant, I learned the hard way that not all flow technologies suit every

Misjudging sewer flow rates can be costly—a Florida contractor faced $120,000 in repairs after undersizing pipes based on wrong flow calculations that caused chronic backups

When your sewage pump station suddenly records a 30% flow discrepancy, it’s often traced to selecting the wrong flow meter technology for the harsh sewer

Imagine your treatment plant suddenly experiencing a 20% drop in flow rate measurement. Within hours, untreated wastewater might bypass treatment and discharge directly into the

Is your flow meter giving inconsistent readings? You’re not alone – over 70% of industrial plants report annual flow measurement issues costing thousands in downtime

Replacing flow meters too soon wastes thousands – here’s how to maximize EMF lifespan. A properly maintained electromagnetic flow meter typically lasts 10-15 years in

Did you know 37% of electromagnetic flow meter failures stem from temperature and contamination issues? Here’s how to prevent them. Standard EMFs handle 0-60°C, while

Wastewater plants lose thousands annually from inaccurate flow measurement – until they switch to EMF technology. Electromagnetic flow meters (EMFs) excel in wastewater by measuring

Buying a $500 electromagnetic flow meter seems like a smart deal—until you discover the true operating costs. While cheaper EMFs have lower upfront costs, they

The right flowmeter choice can save you thousands annually in maintenance and measurement errors. Select flowmeters based on three key factors: fluid properties (conductivity, viscosity,

Facing choice paralysis between flowmeter technologies? The winning solution depends entirely on your specific process requirements and operating conditions. For conductive liquids, electromagnetic flow meters

Your electromagnetic flow meter (EMF) works hard daily – but how do you know when it’s no longer measuring accurately? Watch for these critical failure

HVAC engineers face a frustrating dilemma – mechanical water meters wear out quickly while ultrasonic models struggle with air bubbles. The solution might surprise you.

Raw sewage contains over 1,000 harmful pathogens per milliliter. Without proper treatment, it poses severe environmental risks. Electromagnetic flow meters (EMFs) enable accurate wastewater measurement

One stray metal particle can ruin an entire batch of milk or beer. Food-grade electromagnetic flow meters provide critical protection. Food-grade EMFs use FDA-approved materials

Flow measurement fails when pipes aren’t full. But why does this happen, and what are your alternatives? EMFs require full pipe conditions to work accurately

We will contact you within 1 working day, please pay attention to the email id

“[email protected]”.

Social Chat is free, download and try it now here!