How To Use Differential Pressure Transmitters In HVAC Systems Effectively?

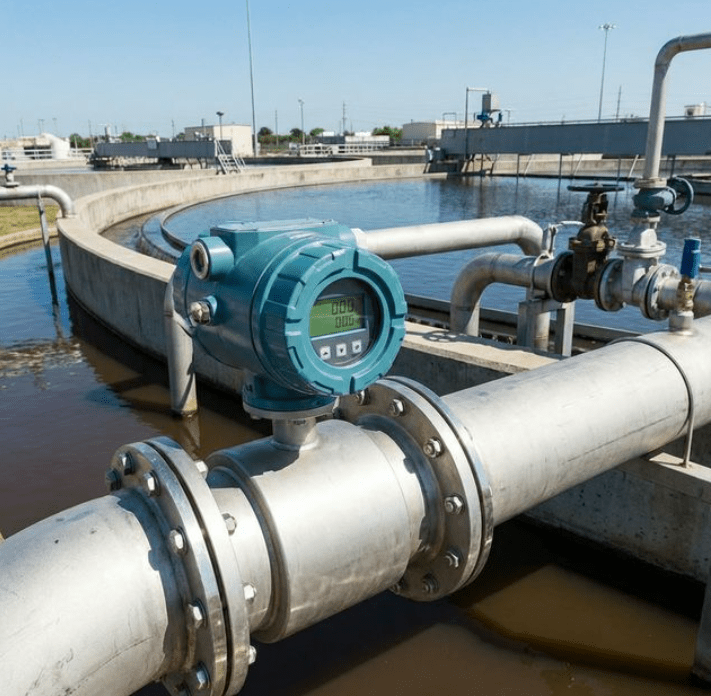

Poor differential pressure monitoring in HVAC systems can lead to inefficient operation and high energy costs. A differential pressure transmitter in HVAC systems measures pressure