Why Mag Meters Dominate Wastewater Plants—And What They Replace

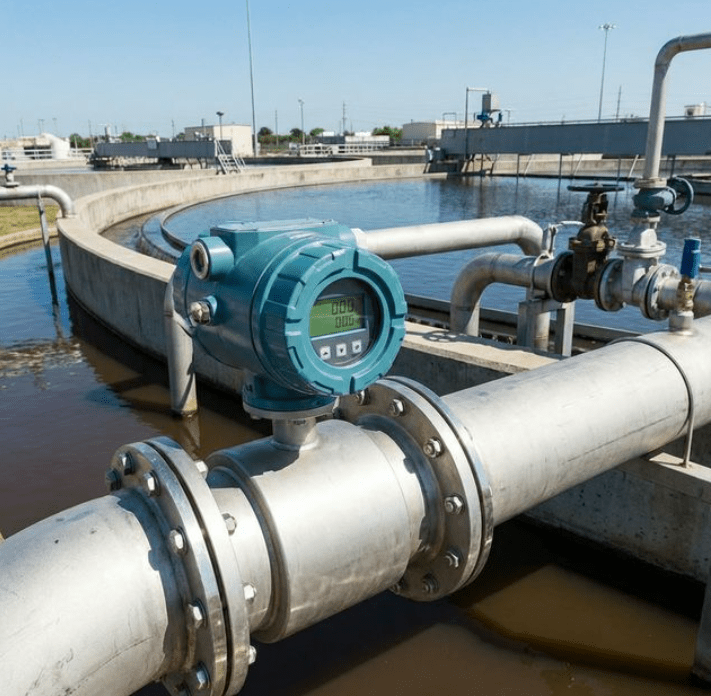

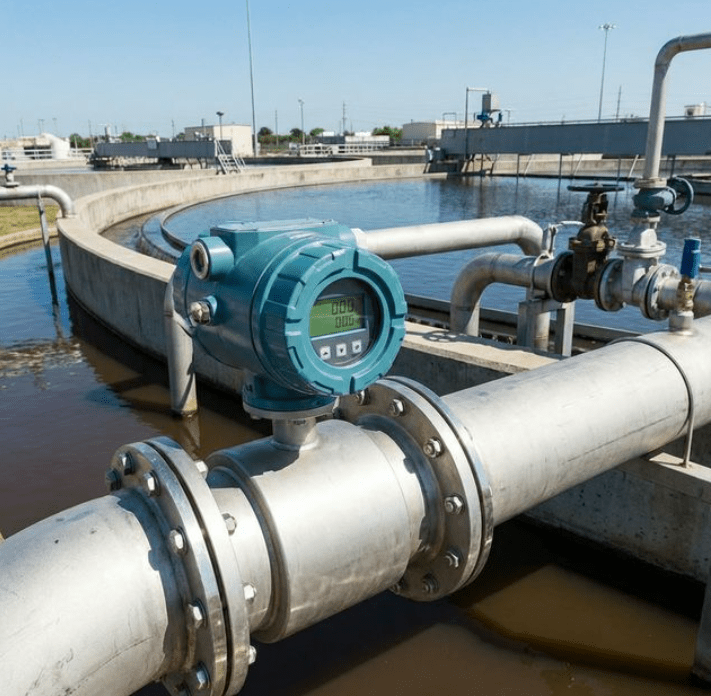

High-reliability electromagnetic flow meter installed on a wastewater treatment plant sludge line "We tried a vortex flow meter on our return activated sludge line. It

High-reliability electromagnetic flow meter installed on a wastewater treatment plant sludge line "We tried a vortex flow meter on our return activated sludge line. It

"We installed three electromagnetic flow meters on our DI water return lines. None of them worked. The readings were completely erratic—jumping from zero to max

Every wastewater treatment operator knows the frustration: you’ve just replaced a clogged Venturi meter on your return activated sludge line—for the third time this year.

Ever watched a sulfuric acid leak destroy a $15,000 inline flow meter—and narrowly miss injuring an operator? In our 15+ years installing flow measurement solutions

Have you ever wondered why your ultrasonic flow meter works perfectly on clean water but completely fails on your chemical slurry line? In our 15+

Struggling to find accurate flow measurement solutions for small diameter pipes? You’re not alone—87% of engineers report challenges when measuring flow in pipes below DN50.

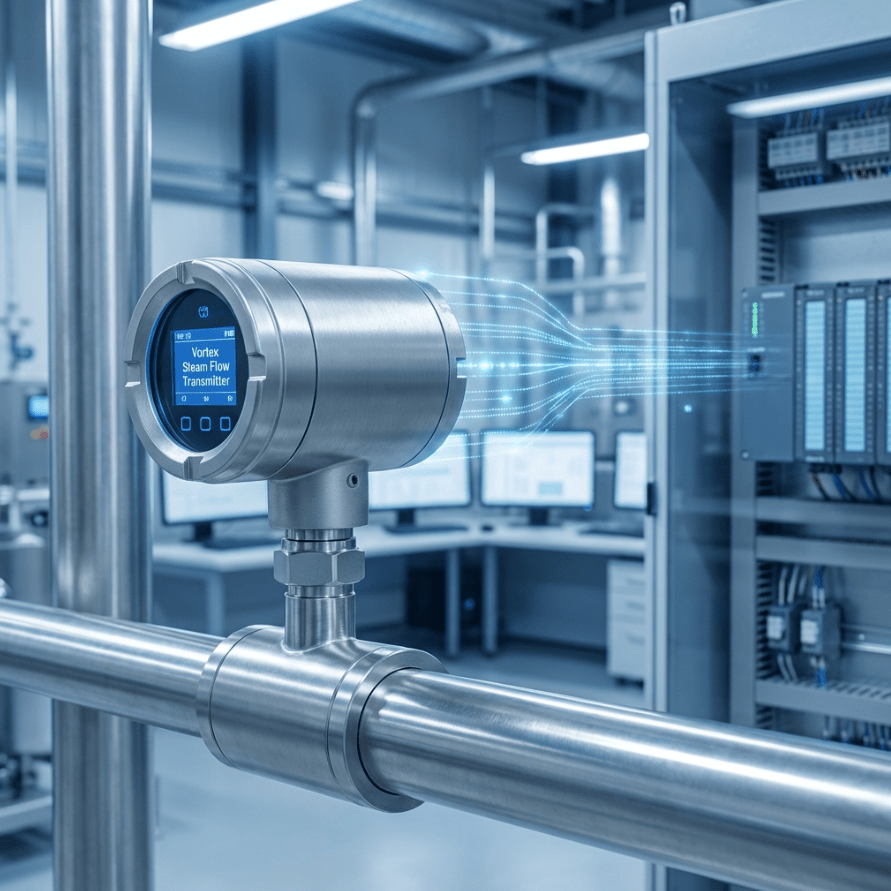

When a paper mill asked us to quote flow meters for their DN400 steam line, they expected to pay $15,000+ for a full-bore inline vortex

When engineers ask us for a flow meter that can handle steam, compressed air, and liquid in the same facility, our first recommendation is almost

In our years of supporting steam measurement systems, the most common question we receive after installation is: "How do I get the flow signal into

Steam is often the second-largest energy cost in industrial facilities—yet studies indicate that 10–30% of generated steam is lost before reaching its intended use point

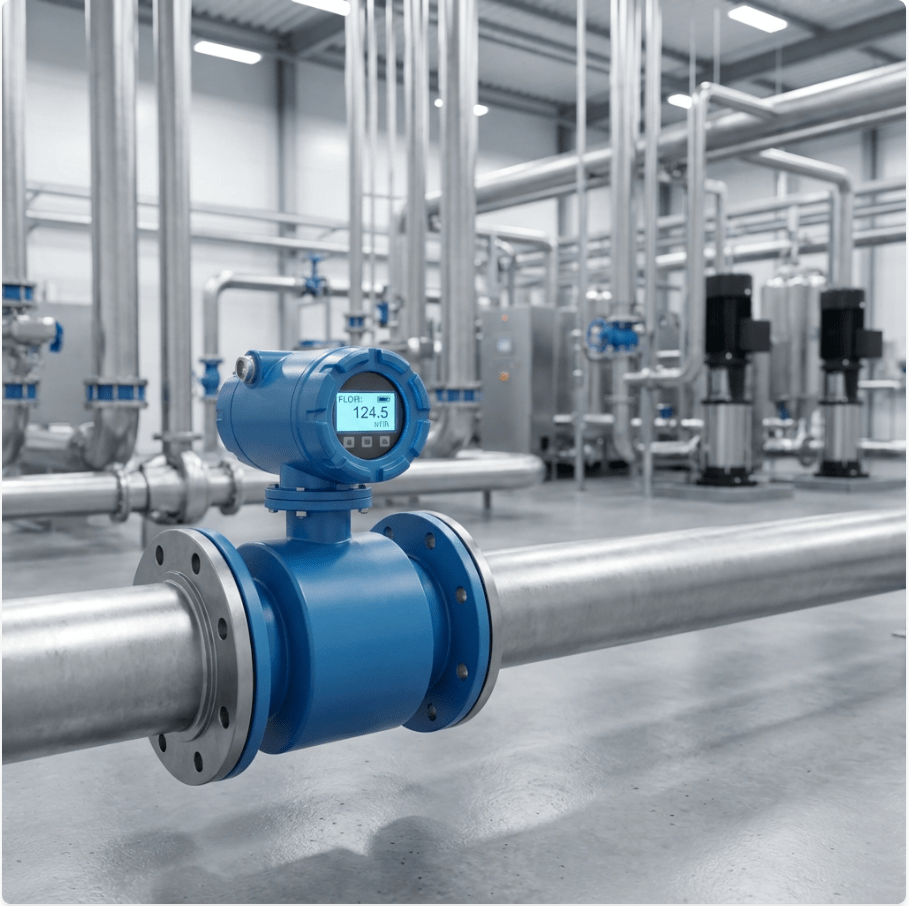

A magnetic flow meter (also known as a magmeter or electromagnetic flow meter) is a precision volumetric flow measurement device designed for conductive liquids in

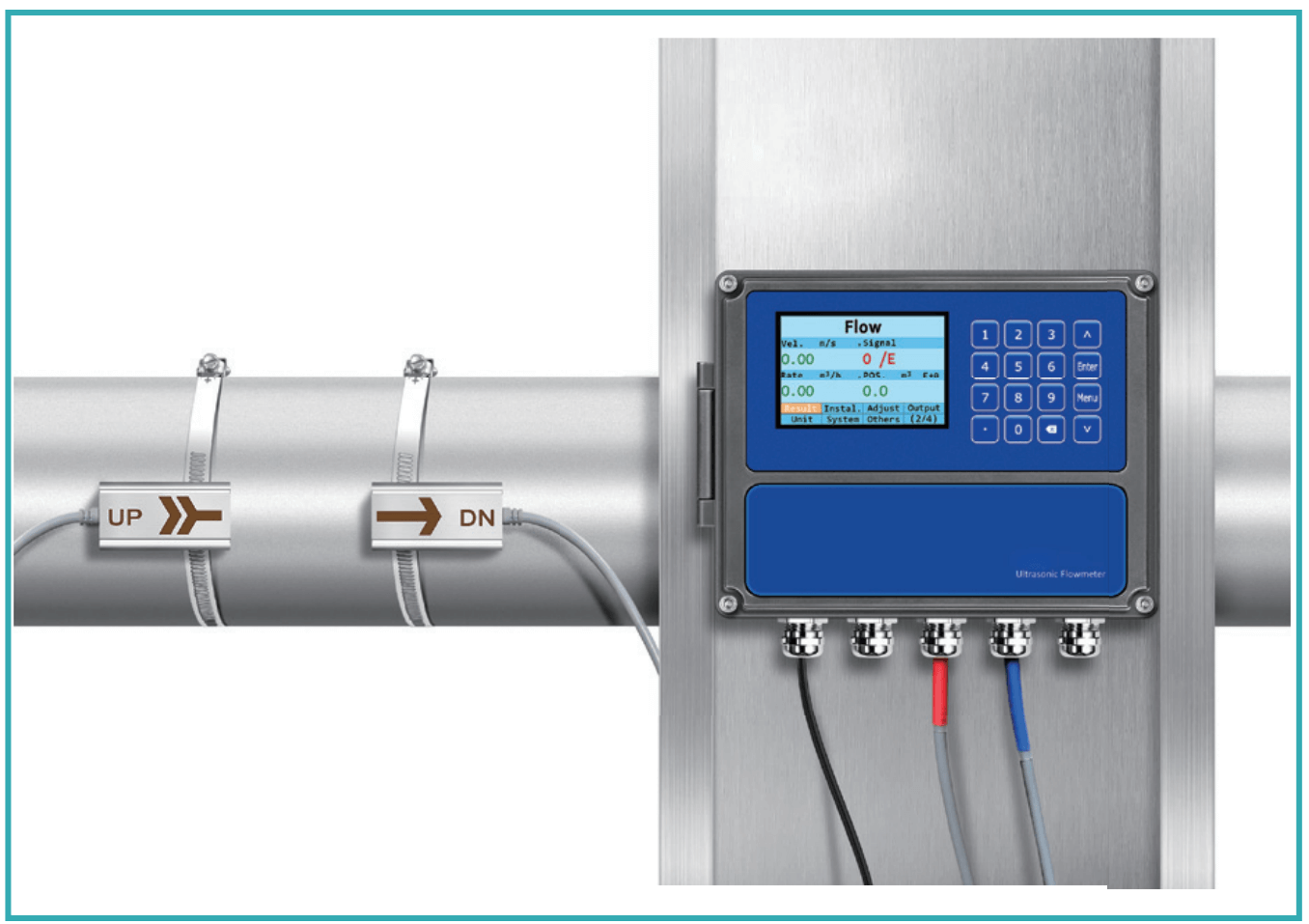

The majority of wall mount ultrasonic flow meters on the market today still use a decades-old design: a plastic enclosure with a small, monochrome LCD

Getting accurate measurements from a clamp on ultrasonic flow meter depends heavily on proper installation. Even the most expensive meter will fail if the transducers

Signal issues are the primary frustration for technicians working with clamp on ultrasonic flow meters. One minute it’s working, the next minute the signal strength

Looking for a flow measurement solution that doesn’t require cutting into your pipes or shutting down your process? A clamp on ultrasonic flow meter offers

Last month, a chemical plant in Texas lost over $50,000 in product due to inaccurate flow measurement. Their traditional mechanical meter had been quietly failing,

Last year, a food processing plant lost $50,000 in product due to inaccurate measurements from an uncalibrated flow meter. Don’t let this happen to you.

Last month, a water utility manager asked me why their new ultrasonic flow meter showed different readings from their old mechanical meter. The answer lies

A facility manager once lost $50,000 monthly due to undetected water leaks. Without proper flow monitoring, businesses face significant losses in resources and revenue. Ultrasonic

Many facilities struggle with accurate wastewater flow measurement, leading to inefficient operations and compliance issues. An electromagnetic flow meter uses Faraday’s law of electromagnetic induction

Choosing the wrong flow meter for wastewater applications can lead to measurement errors, maintenance issues, and increased operational costs. Wastewater flow meters include magnetic flowmeters,

Inaccurate wastewater flow measurement leads to treatment inefficiencies, compliance issues, and increased operational costs. To measure wastewater flow rate, use appropriate flow meters like magnetic,

Inefficient wastewater treatment can lead to environmental violations and increased operational costs without proper flow measurement. A flow meter in wastewater treatment is a device

Many wastewater treatment operators struggle with inaccurate flow measurements, leading to inefficient treatment processes and compliance issues. To calculate wastewater flow rate, you can use

Many industrial users waste money on magnetic flowmeters only to discover they won’t work with their non-conductive liquids like oils or pure water. Magnetic flowmeters

Choosing the wrong flow measurement technology can lead to significant accuracy issues and unnecessary maintenance costs in industrial processes. The most suitable flow measurement technology

Many plant operators face unexpected measurement failures when using magnetic flow meters with low-conductivity fluids. Fluid conductivity directly affects magnetic flow meter performance, with a

Many industrial users struggle with meeting regulatory requirements due to incorrect flow meter calibration practices. Flow meter calibration standards primarily follow ISO 17025, ISO/IEC 9001,

Incorrect sewage pipe calculations can lead to costly overflows, backups, and environmental hazards. Sewage pipe calculations involve determining pipe diameter based on flow rate, slope,

Measuring sludge flow accurately can be challenging due to its varying consistency and high solid content. For sludge applications, electromagnetic flow meters are typically the

Accurate sewer flow measurement is crucial for preventing environmental disasters and maintaining public health standards. Sewer flow measurement typically involves using specialized flow meters designed

A process engineer once lost days of production due to air bubbles in a horizontally installed magnetic flow meter. The solution? Vertical installation. Yes, magnetic

Calculating K-factor wrongly can lead to significant measurement errors and costly process control issues. The K-factor in vortex flow meters represents the number of pulses

Factory teams often face challenges when installing vortex meters, leading to inaccurate measurements and unnecessary downtime. Proper installation makes all the difference. Vortex flow meters

Managing flow measurement in high-temperature processes poses significant challenges, often leading to equipment failure and inaccurate readings. Vortex flow meters can handle process temperatures up

Plant managers often struggle with accurate compressed air flow measurement, leading to energy waste and inefficient system operation. Vortex flow meters are ideal for compressed

Many industrial users struggle with selecting the right flow meter for their water measurement needs, often leading to costly mistakes and inefficient operations. Vortex flow

Selecting the wrong flow meter for natural gas can lead to significant measurement errors and costly operational inefficiencies. For natural gas measurement, vortex flow meters

Flow meter accuracy issues can cost thousands in wasted product and energy, yet many operators overlook proper calibration. Vortex flow meters require regular calibration, typically

Many industrial processes face challenges in selecting the right flow measurement technology for their specific needs. Vortex flow meters are widely used in steam systems,

Many engineers struggle with flow measurement accuracy, often wondering if their vortex meters deliver the precision they need. Vortex flow meters typically achieve accuracy rates

Steam flow measurement challenges often lead to inaccurate readings and wasted energy in industrial processes. Vortex flow meters are ideal for steam applications due to

Engineers often struggle to choose the right flow meter for their applications, especially when dealing with steam and gas measurements. A vortex flow meter works

Facing issues with DP transmitters can halt production and cause significant losses in industrial processes. To troubleshoot a DP transmitter, follow a systematic approach: check

Many engineers struggle with choosing between pressure and differential pressure transmitters, leading to costly mistakes and inefficient system designs. Pressure transmitters measure absolute or gauge

Understanding differential pressure transmitter operation can be complex, leading to measurement errors and system inefficiencies. A differential pressure transmitter works by measuring the pressure difference

Last month, a chemical plant discovered their process efficiency dropped by 15% due to incorrect transmitter mounting. A costly mistake that could have been avoided.

Incorrect installation of differential pressure transmitters can lead to inaccurate measurements and system failures. Differential pressure transmitters for liquids should be installed at points where

Poor sensor placement in chilled water systems leads to inaccurate readings and inefficient system operation. Differential pressure sensors in chilled water systems should be installed

Improper boiler pressure monitoring can lead to dangerous operating conditions and inefficient steam production. A differential pressure transmitter in boilers measures pressure differences between two

We will contact you within 1 working day, please pay attention to the email id

“[email protected]”.

Social Chat is free, download and try it now here!