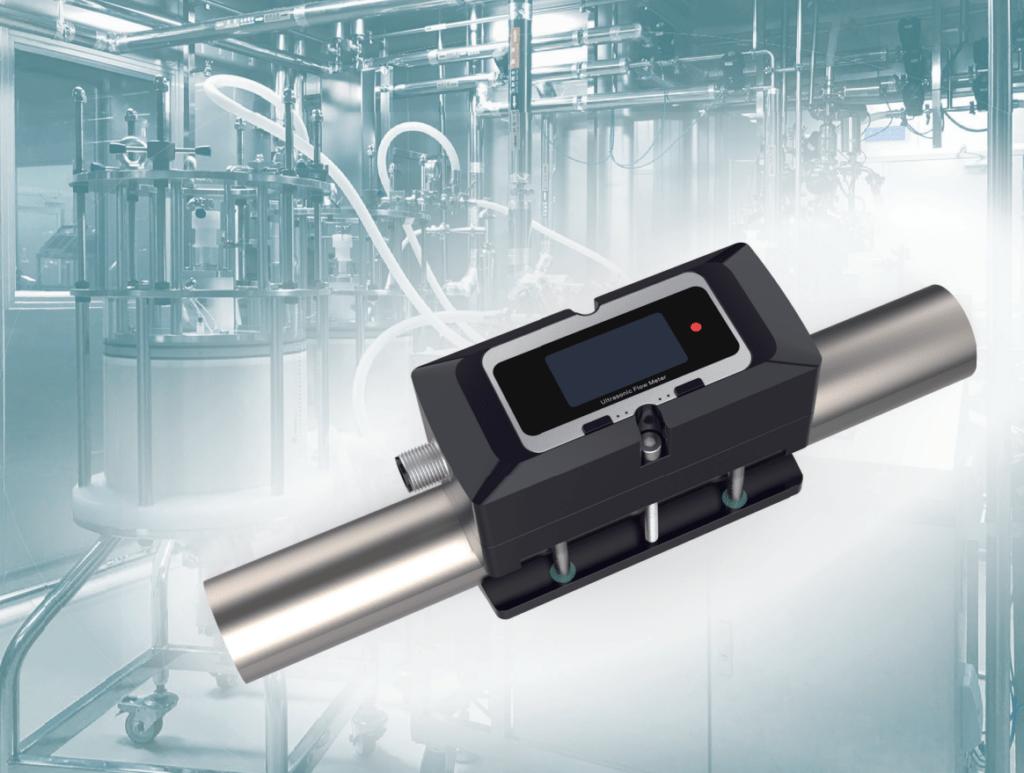

Small Pipe Ultrasonic Flow Meter: Complete Guide for DN10-DN40 Applications

Struggling to find accurate flow measurement solutions for small diameter pipes? You’re not alone—87% of engineers report challenges when measuring flow in pipes below DN50. Quick Answer: Small pipe ultrasonic flow meters (DN10-DN40) use transit-time technology with specialized compact transducers to measure liquid flow rates from 1-400 LPM without cutting pipes. Modern clamp-on designs like […]

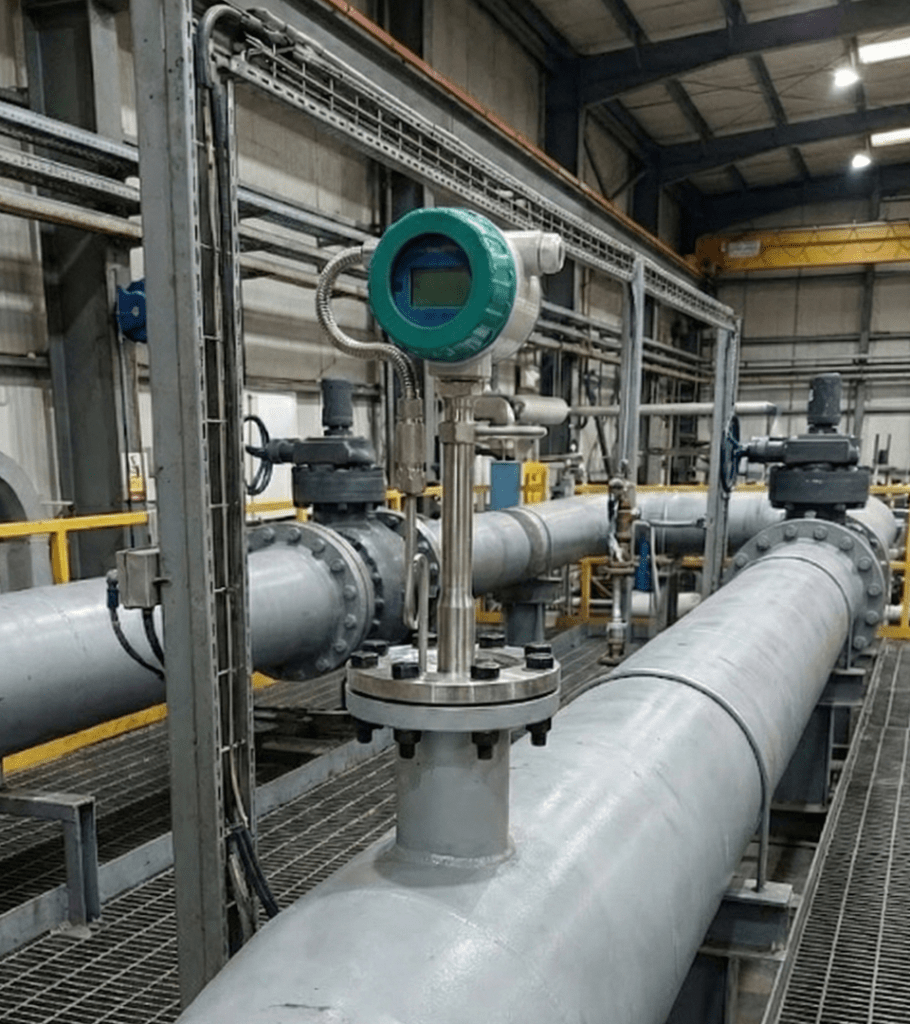

Insertion Vortex Flow Meter: Save 50% on Large Pipes (DN200+)

When a paper mill asked us to quote flow meters for their DN400 steam line, they expected to pay $15,000+ for a full-bore inline vortex meter. We proposed an insertion vortex flow meter instead — at less than half the cost, with comparable accuracy. This is the reality for large pipe applications: insertion vortex flow […]

Vortex Flow Measurement: How It Works & When It Fails

When engineers ask us for a flow meter that can handle steam, compressed air, and liquid in the same facility, our first recommendation is almost always vortex flow measurement technology. Why? Because vortex meters have no moving parts, work across a wide range of Reynolds numbers, and can accurately measure liquid, gas, and steam — […]

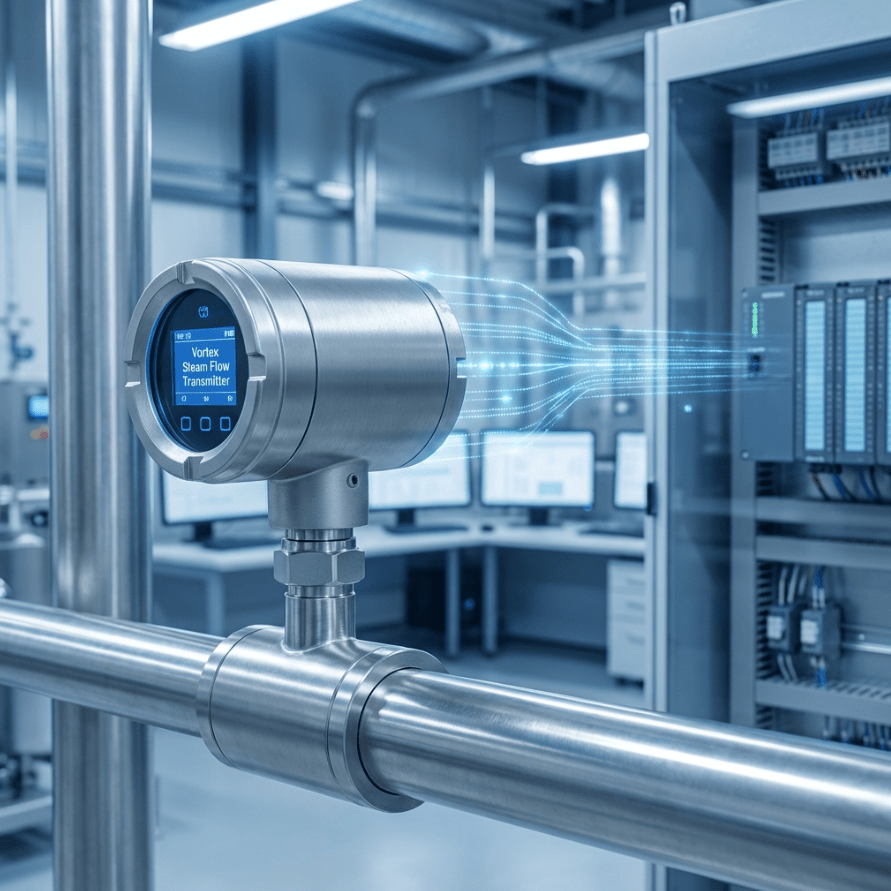

Steam Flow Transmitter: Signals, DCS Integration & Specs

In our years of supporting steam measurement systems, the most common question we receive after installation is: "How do I get the flow signal into my DCS?" Many engineers install a steam flow meter only to realize the raw sensor signal cannot be directly read by their control system. The solution? A steam flow transmitter […]

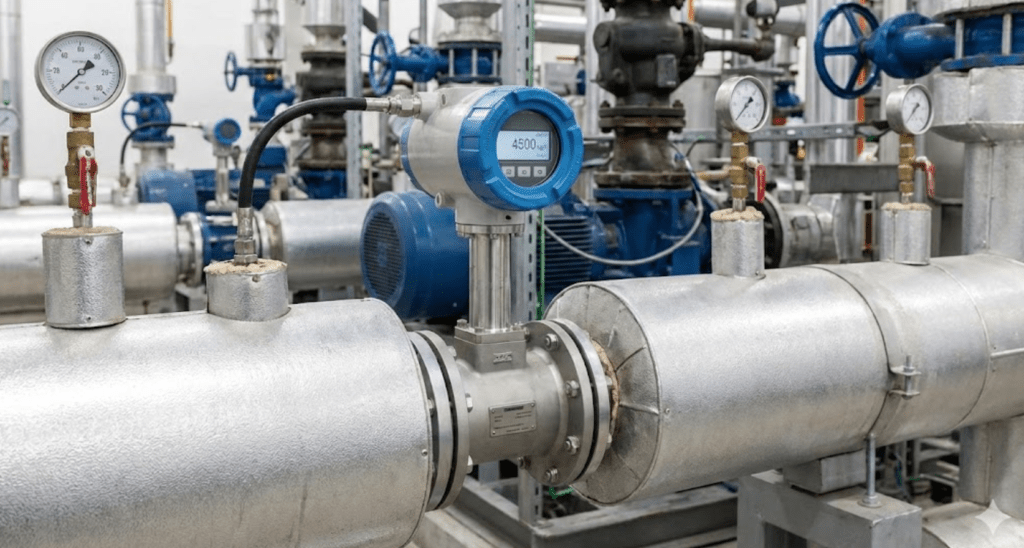

Steam Flow Meter: Types, Selection & Best Practices

Steam is often the second-largest energy cost in industrial facilities—yet studies indicate that 10–30% of generated steam is lost before reaching its intended use point due to leaks, poor condensate return, and inaccurate metering (U.S. Department of Energy). Without reliable measurement, energy waste goes undetected and uncontrolled. A steam flow meter (also called a steam […]

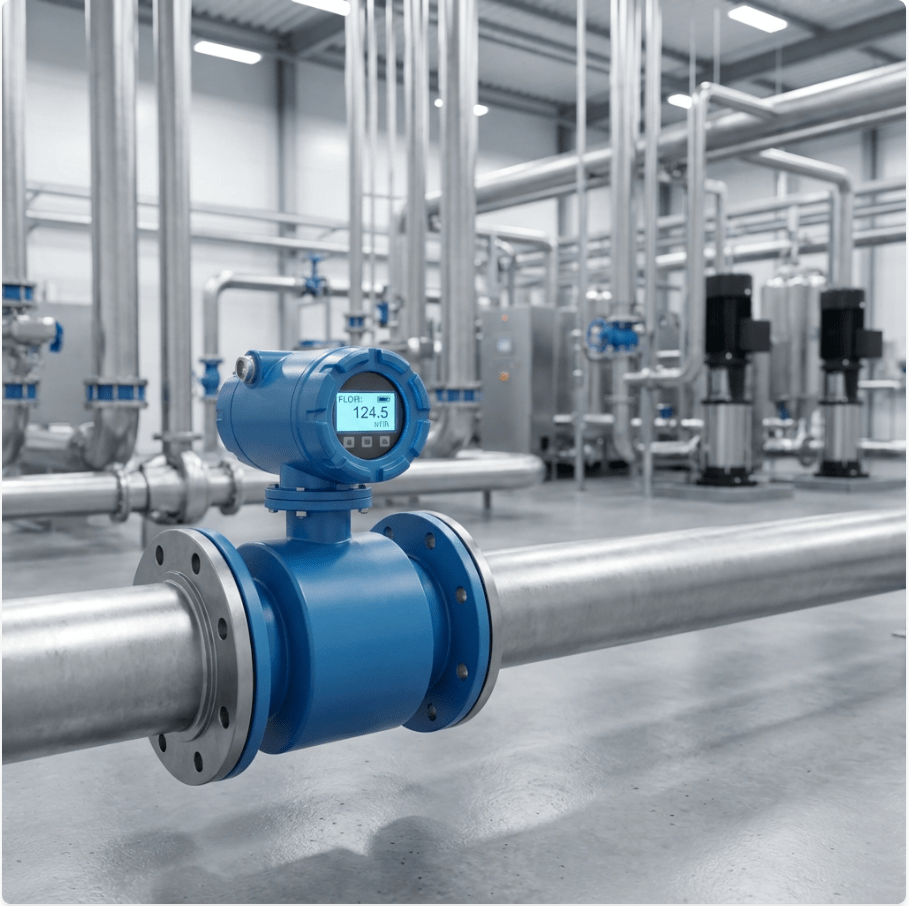

Magnetic Flow Meter: How It Works & Selection Guide

A magnetic flow meter (also known as a magmeter or electromagnetic flow meter) is a precision volumetric flow measurement device designed for conductive liquids in closed pipes. Distinguished by its obstruction-free design, the magnetic flow meter creates virtually no additional pressure drop and contains no moving parts to wear out. It is the industry standard […]

Wall Mount Ultrasonic Flow Meter: Built to Last with Metal & Color TFT

The majority of wall mount ultrasonic flow meters on the market today still use a decades-old design: a plastic enclosure with a small, monochrome LCD screen. While this configuration gets the job done initially, it often fails to meet the demands of long-term industrial use. Plastic degrades. Screens become unreadable. And technicians waste valuable time […]

How to Install a Clamp On Ultrasonic Flow Meter: Step-by-Step Guide

Getting accurate measurements from a clamp on ultrasonic flow meter depends heavily on proper installation. Even the most expensive meter will fail if the transducers aren’t mounted correctly. In this guide, we’ll cover the essential steps to ensure a strong signal and reliable data. 1. Verify Upstream and Downstream Requirements Like all flow meters, clamp […]

Clamp On Ultrasonic Flow Meter Troubleshooting Checklist

Signal issues are the primary frustration for technicians working with clamp on ultrasonic flow meters. One minute it’s working, the next minute the signal strength drops to zero. Use this quick troubleshooting checklist to identify the root cause and get your meter back on track. Quick Reference: Common Symptoms & Fixes Symptom Likely Cause Quick […]

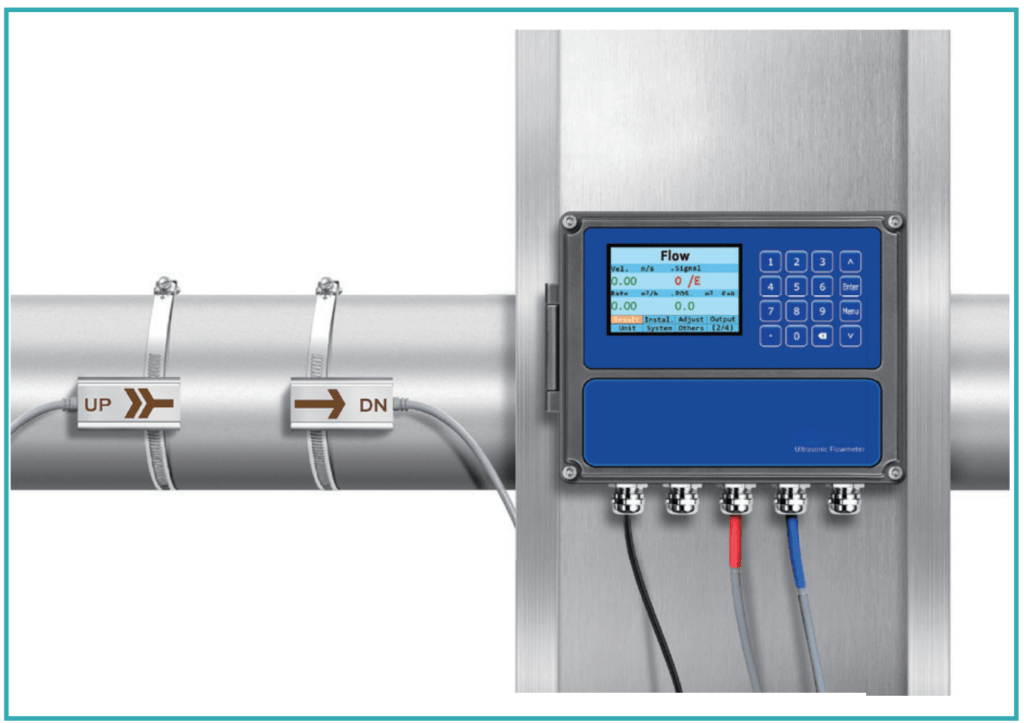

Clamp On Ultrasonic Flow Meter: The Complete Guide to Non-Invasive Flow Measurement

Looking for a flow measurement solution that doesn’t require cutting into your pipes or shutting down your process? A clamp on ultrasonic flow meter offers non-invasive, highly accurate liquid flow measurement with no moving parts and minimal maintenance—making it the go-to choice for modern industrial applications. In this guide, I’ll walk you through everything you […]

The Complete Guide Of Ultrasonic Flow Meter

Last month, a chemical plant in Texas lost over $50,000 in product due to inaccurate flow measurement. Their traditional mechanical meter had been quietly failing, leading to incorrect batch mixing. This common scenario highlights why choosing the right flow meter is crucial. Ultrasonic flow meters use sound wave technology to measure liquid flow, offering non-invasive […]

How Often Do Flow Meters Need To Be Calibrated?

Last year, a food processing plant lost $50,000 in product due to inaccurate measurements from an uncalibrated flow meter. Don’t let this happen to you. Most flow meters require calibration every 12-18 months, but frequency depends on the application, fluid type, and regulatory requirements. Critical processes may need more frequent calibration. Flow Meter Calibration Schedule […]

How Accurate Are Ultrasonic Flow Meters?

Last month, a water utility manager asked me why their new ultrasonic flow meter showed different readings from their old mechanical meter. The answer lies in understanding true measurement accuracy. Modern ultrasonic flow meters can achieve accuracy rates of ±0.5% to ±1.0% of reading under optimal conditions. Their accuracy depends on installation quality, fluid properties, […]

What Are Ultrasonic Flow Meters Used For?

A facility manager once lost $50,000 monthly due to undetected water leaks. Without proper flow monitoring, businesses face significant losses in resources and revenue. Ultrasonic flow meters are used for non-invasive flow measurement in industrial processes, municipal water systems, oil and gas operations, and HVAC systems. They provide accurate, real-time flow data without disrupting the […]

What Is An Electromagnetic Flow Meter For Wastewater?

Many facilities struggle with accurate wastewater flow measurement, leading to inefficient operations and compliance issues. An electromagnetic flow meter uses Faraday’s law of electromagnetic induction to measure conductive fluid flow in pipes, providing accurate measurements for wastewater applications. Electromagnetic Flow Meter Basic Structure Let me explain how electromagnetic flow meters work in wastewater applications, based […]

What Are The Different Types Of Wastewater Flow Meters?

Choosing the wrong flow meter for wastewater applications can lead to measurement errors, maintenance issues, and increased operational costs. Wastewater flow meters include magnetic flowmeters, ultrasonic meters, area-velocity sensors, and open channel measurement devices, each designed for specific applications. Let me share my experience with different types of wastewater flow meters and their applications. What […]

How To Measure The Flow Rate Of Wastewater?

Inaccurate wastewater flow measurement leads to treatment inefficiencies, compliance issues, and increased operational costs. To measure wastewater flow rate, use appropriate flow meters like magnetic, ultrasonic, or open channel devices, combined with proper installation and regular calibration. Let me share my experience in implementing effective wastewater flow measurement solutions. How Do You Measure Wastewater Flow? […]

What Is A Flow Meter In Wastewater Treatment?

Inefficient wastewater treatment can lead to environmental violations and increased operational costs without proper flow measurement. A flow meter in wastewater treatment is a device that measures the volume of water passing through a pipe or channel, crucial for process control and regulatory compliance. I’ve worked with numerous wastewater treatment plants, and I’ll share my […]

How To Calculate Wastewater Flow Rate?

Many wastewater treatment operators struggle with inaccurate flow measurements, leading to inefficient treatment processes and compliance issues. To calculate wastewater flow rate, you can use the velocity-area method (Q = V × A), where Q is flow rate, V is fluid velocity, and A is pipe cross-sectional area. > Wastewater Flow Rate Calculation Methods Let […]

Which Liquid Cannot Be Measured By The Magnetic Flowmeter?

Many industrial users waste money on magnetic flowmeters only to discover they won’t work with their non-conductive liquids like oils or pure water. Magnetic flowmeters cannot measure non-conductive liquids such as oils, hydrocarbons, ultra-pure water, and most organic chemicals due to their requirement for fluid conductivity above 5µS/cm. Non-conductive Liquids and Magnetic Flowmeters Let me […]

The Best Flow Measurement Technologies for Different Fluid Types

Choosing the wrong flow measurement technology can lead to significant accuracy issues and unnecessary maintenance costs in industrial processes. The most suitable flow measurement technology depends on the fluid type, with Coriolis meters offering highest accuracy for liquids, while ultrasonic meters excel in clean fluids and electromagnetic meters in conductive liquids. Let me share my […]

Does Conductivity Affect Magnetic Flow Meter?

Many plant operators face unexpected measurement failures when using magnetic flow meters with low-conductivity fluids. Fluid conductivity directly affects magnetic flow meter performance, with a minimum requirement of 5 μS/cm for standard meters. Lower conductivity leads to unreliable measurements or complete meter failure. I’ve seen numerous cases where understanding conductivity requirements could have prevented costly […]

What Is The Standard For Calibration Of Flowmeter?

Many industrial users struggle with meeting regulatory requirements due to incorrect flow meter calibration practices. Flow meter calibration standards primarily follow ISO 17025, ISO/IEC 9001, and NIST guidelines, requiring traceability, documented procedures, and specified accuracy limits. Flow Meter Calibration Standards Overview Let me share my experience in implementing calibration standards across various industries. What Is […]

How Do You Calculate Sewage Pipes?

Incorrect sewage pipe calculations can lead to costly overflows, backups, and environmental hazards. Sewage pipe calculations involve determining pipe diameter based on flow rate, slope, roughness coefficient, and expected peak loads using Manning’s equation. Sewage Pipe Calculation Methods Let me share my experience in designing and implementing sewage systems across various projects. How To Calculate […]

What Is The Best Flow Meter For Sludge?

Measuring sludge flow accurately can be challenging due to its varying consistency and high solid content. For sludge applications, electromagnetic flow meters are typically the best choice due to their ability to handle high solid content, no moving parts, and maintenance-friendly design. Sludge Flow Meter Application Let me share insights from my experience in implementing […]

How Do You Measure Sewer Flow?

Accurate sewer flow measurement is crucial for preventing environmental disasters and maintaining public health standards. Sewer flow measurement typically involves using specialized flow meters designed for wastewater, including ultrasonic flow meters, area-velocity meters, and electromagnetic flow meters. Sewer Flow Measurement Methods Let me share my experience in implementing various sewer flow measurement solutions across different […]

Can Magnetic Flow Meters Be Installed Vertically?

A process engineer once lost days of production due to air bubbles in a horizontally installed magnetic flow meter. The solution? Vertical installation. Yes, magnetic flow meters can be installed vertically. In fact, vertical installation is often preferred as it helps prevent air bubble accumulation and ensures the pipe stays full. Magnetic Flow Meters Let […]

How To Calculate K-Factor For Vortex Flow Meter?

Calculating K-factor wrongly can lead to significant measurement errors and costly process control issues. The K-factor in vortex flow meters represents the number of pulses generated per unit volume of fluid flow, typically expressed as pulses/m³ or pulses/gallon. K-Factor Calculation Diagram Let me share my experience with K-factor calculations and calibrations from numerous field installations. […]

What Are The Essential Guidelines For Vortex Flow Meter Installation?

Factory teams often face challenges when installing vortex meters, leading to inaccurate measurements and unnecessary downtime. Proper installation makes all the difference. Vortex flow meters require 15 pipe diameters (15D) upstream and 5D downstream straight piping, proper orientation based on fluid type, adequate supports to minimize vibration, and environmental protection from extreme conditions. The minimum […]

How Do Vortex Flow Meters Perform in High Temperature Applications?

Managing flow measurement in high-temperature processes poses significant challenges, often leading to equipment failure and inaccurate readings. Vortex flow meters can handle process temperatures up to 400°C (752°F) with standard sensors, while special high-temperature versions can measure flows at temperatures reaching 800°C (1472°F). High Temperature Vortex Flow Meter Let me share insights from my experience […]

Why Choose Vortex Flow Meters For Compressed Air Measurement?

Plant managers often struggle with accurate compressed air flow measurement, leading to energy waste and inefficient system operation. Vortex flow meters are ideal for compressed air measurement, offering accuracy up to ±1% in pipes from 15mm to 300mm, with stable performance across varying pressures and temperatures. Vortex Flow Meter in Compressed Air System Let me […]

What Makes Vortex Flow Meters Ideal For Water Applications?

Many industrial users struggle with selecting the right flow meter for their water measurement needs, often leading to costly mistakes and inefficient operations. Vortex flow meters are excellent for water applications, offering 1% accuracy, no moving parts, and reliable performance in pipe sizes from 15mm to 300mm, making them ideal for clean liquid measurement. Vortex […]

Which Flow Meter Is Best For Natural Gas Measurement?

Selecting the wrong flow meter for natural gas can lead to significant measurement errors and costly operational inefficiencies. For natural gas measurement, vortex flow meters offer excellent accuracy and reliability, especially in high-pressure applications, with typical accuracies of ±1% of reading and high turndown ratios. Flow Meter Types for Natural Gas Let me share my […]

How To Properly Calibrate A Vortex Flow Meter For Maximum Accuracy?

Flow meter accuracy issues can cost thousands in wasted product and energy, yet many operators overlook proper calibration. Vortex flow meters require regular calibration, typically annually, to maintain their accuracy of ±0.5% to ±1.0% for liquids and ±1.0% to ±2.0% for gases and steam. Vortex Flow Meter Calibration Process Let me share my experience with […]

What Are The Main Applications Of Vortex Flow Meters In Industry?

Many industrial processes face challenges in selecting the right flow measurement technology for their specific needs. Vortex flow meters are widely used in steam systems, compressed air monitoring, natural gas measurement, and liquid applications where their robust design and reliability make them ideal choices. Vortex Flow Meter Industrial Applications Let me share my experience with […]

What Is The Accuracy Of A Vortex Flow Meter And How Does It Compare?

Many engineers struggle with flow measurement accuracy, often wondering if their vortex meters deliver the precision they need. Vortex flow meters typically achieve accuracy rates of ±0.5% to ±1.0% of reading for liquids and ±1.0% to ±2.0% for gases and steam, with excellent repeatability. Flow Meter Accuracy Comparison Let me share insights from my experience […]

Why Choose Vortex Flow Meters For Steam Applications?

Steam flow measurement challenges often lead to inaccurate readings and wasted energy in industrial processes. Vortex flow meters are ideal for steam applications due to their resistance to high temperatures, pressure variations, and ability to handle saturated and superheated steam conditions. Vortex Flow Meter in Steam Service Let me share my experience with steam flow […]

How Does A Vortex Flow Meter Work And What Makes It Unique?

Engineers often struggle to choose the right flow meter for their applications, especially when dealing with steam and gas measurements. A vortex flow meter works by creating and measuring vortices in the fluid flow. When fluid passes a bluff body, it creates alternating vortices whose frequency is proportional to the flow rate. Vortex Flow Meter […]

What Are The Essential Steps For DP Transmitter Troubleshooting?

Facing issues with DP transmitters can halt production and cause significant losses in industrial processes. To troubleshoot a DP transmitter, follow a systematic approach: check power supply, verify process connections, inspect impulse lines, validate zero/span calibration, and test output signal. DP Transmitter Troubleshooting Guide Let me share proven troubleshooting methods based on my extensive field […]

What Are The Main Differences Between Pressure And Differential Pressure Transmitters?

Many engineers struggle with choosing between pressure and differential pressure transmitters, leading to costly mistakes and inefficient system designs. Pressure transmitters measure absolute or gauge pressure at a single point, while differential pressure transmitters measure the difference in pressure between two points, each serving distinct industrial applications. Pressure vs Differential Pressure Comparison I’ve worked with […]

How Do Differential Pressure Transmitters Work In Industrial Applications?

Understanding differential pressure transmitter operation can be complex, leading to measurement errors and system inefficiencies. A differential pressure transmitter works by measuring the pressure difference between two points using a sensing element, typically a diaphragm, which converts pressure differences into electrical signals. DP Transmitter Operation Principle Let me explain how these devices work based on […]

What Is The Best Mounting Position For Differential Pressure Transmitters?

Last month, a chemical plant discovered their process efficiency dropped by 15% due to incorrect transmitter mounting. A costly mistake that could have been avoided. For most applications, the best mounting position for differential pressure transmitters is below the process taps with impulse lines sloping upward at least 1/10 inch per foot. This ensures air […]

Where Should You Install Differential Pressure Transmitters For Liquid Applications?

Incorrect installation of differential pressure transmitters can lead to inaccurate measurements and system failures. Differential pressure transmitters for liquids should be installed at points where pressure differences need to be measured, such as across filters, pumps, or tanks, with proper consideration for air bubbles and sediment accumulation. DP Transmitter Installation Overview Let me share our […]

What Is The Best Location For Differential Pressure Sensors In Chilled Water Systems?

Poor sensor placement in chilled water systems leads to inaccurate readings and inefficient system operation. Differential pressure sensors in chilled water systems should be installed at critical points in the distribution network, typically at the most hydraulically remote load or at points representing 75-90% of the total system pressure drop. Chilled Water System Overview Let […]

How Do Differential Pressure Transmitters Work In Boiler Systems?

Improper boiler pressure monitoring can lead to dangerous operating conditions and inefficient steam production. A differential pressure transmitter in boilers measures pressure differences between two points to monitor water level, steam flow, and system performance, ensuring safe and efficient boiler operation. Boiler DP System Overview Let me share our expertise in implementing differential pressure solutions […]

How To Use Differential Pressure Transmitters In HVAC Systems Effectively?

Poor differential pressure monitoring in HVAC systems can lead to inefficient operation and high energy costs. A differential pressure transmitter in HVAC systems measures pressure differences between two points to monitor airflow, filter conditions, and system performance, helping maintain optimal indoor air quality and energy efficiency. HVAC DP System Overview Let me share our experience […]

Can You Use A Differential Pressure Transmitter For Water Applications?

Water level measurement errors can cause serious operational problems in water treatment and storage facilities. Yes, you can measure water level using pressure. A differential pressure transmitter measures water level by detecting the hydrostatic pressure created by the water column, where 1 meter of water equals approximately 0.098 bar of pressure. Water Level DP Measurement […]

How To Accurately Measure Tank Level With Differential Pressure Transmitters?

Tank level measurement errors can lead to serious inventory discrepancies and safety issues. A differential pressure transmitter measures tank level by comparing the pressure at the tank bottom (caused by liquid height) to a reference pressure, typically atmospheric pressure for open tanks. DP Tank Level Measurement System Let me share our experience in implementing DP […]

How Does A Differential Pressure Transmitter Work For Flow Measurement?

Many process engineers struggle with understanding how DP transmitters can accurately measure flow rates. A DP transmitter measures flow by calculating the pressure difference between two points in a pipe using a primary element (like an orifice plate), converting this pressure drop into flow rate using the square root relationship. > DP Flow Measurement Principle […]

How Do You Accurately Measure Differential Pressure Transmitter Performance?

Many instrument technicians struggle with understanding and verifying DP transmitter accuracy specifications. Differential pressure transmitter accuracy is typically expressed as a percentage of span or URL (Upper Range Limit), including factors like linearity, hysteresis, and repeatability. DP Transmitter Accuracy Overview Let me share our experience in dealing with accuracy specifications and calibration procedures. How To […]